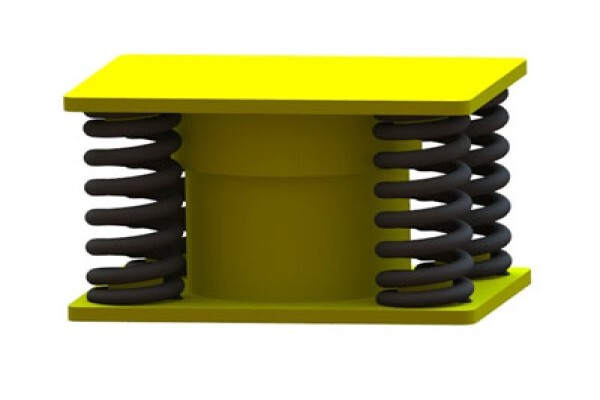

GRB-A type Damping textile machinery isolator

The GRB-A damping vibration isolator reduces vibrations in textile machinery, improving stability, precision, and lifespan. It suppresses dynamic loads, prevents resonance, and provides seismic protection. With anti-slip pads and overload protection, it ensures safe operation. The isolator has a lifespan of over 30 years with minimal maintenance.

Why is the GRB-A type damping vibration isolator best suited for textile machinery?

This equipment features high-speed rotating rollers that often generate vibrations between the machine and its foundation. To prevent issues like machine settlement and distortion, concrete foundation blocks or damping platforms are typically used. The GRB-A precision spring damping vibration isolator effectively addresses these vibration concerns while offering added seismic protection.

Application of GRB-A Type Damping Vibration Isolator in Textile Machinery

The GRB-A type vibration isolator is specially engineered to mitigate vibrations in textile machinery, where high-speed rotating rollers often cause substantial vibration between the equipment and its foundation.

By incorporating this isolator, textile machines experience a reduction in vibration, resulting in smoother operation, improved accuracy in processing, and a longer service life for the equipment. It also minimizes issues like settlement and deformation, removing the need for additional foundation support. Furthermore, the GRB-A isolator offers enhanced seismic protection, safeguarding the equipment’s performance in challenging environments.

What are the advantages of the GRB-A type damping spring isolator

Effectively absorbs dynamic loads, prevents resonance, and isolates over 90% of vibrations.

Boasts a lifespan of over 30 years with minimal maintenance required.

Features anti-seismic capabilities, allowing for easy realignment and leveling of machines if the foundation settles.

Utilizes anti-slip pads, eliminating the need for bolt fixation.

Comes with overload protection, safeguarding the isolator during emergencies and protecting the equipment, ensuring safe and reliable operation.

Includes a load display indicator, simplifying installation, leveling, and maintenance, and enabling continuous monitoring of the isolator’s load condition.