KHD Hand-built Wrapped Bellow

KHD Hand-Wrapped Pipe Flexible Joints feature an economical integral flange design, primarily suited for applications requiring significant movement. These joints are constructed in a W-shaped configuration, made with at least one to two layers of reinforced fabric and vulcanized into a homogeneous product. Available finished thickness options include 3/16 inches, 1/4 inches, or 3/8 inches. KHD utilizes a pre-molded arch design, where the flanges are an integral part of the expansion joint structure. The arch extends through the corner and fully expands in the neutral position.

What is the KHD Hand-built wrapped rubber joint?

KHD Hand-Wrapped Pipe Flexible Joints have several notable characteristics that make them suitable for demanding applications:

Integral Flange Design: The joints feature an economical one-piece flange design, providing strength and reducing the potential for leakage.

W-Shaped Configuration: Their unique W-shaped configuration allows for significant movement and flexibility, accommodating thermal expansion and contraction in piping systems.

Reinforced Fabric Layers: Constructed with one to two layers of reinforced fabric, these joints offer enhanced durability and resistance to wear and tear.

Vulcanized Construction: The joints are vulcanized to form a homogeneous product, ensuring consistent quality and performance.

Various Thickness Options: Available in thicknesses of 3/16 inches, 1/4 inches, or 3/8 inches, allowing for customization based on application requirements.

Pre-Molded Arch Design: The pre-molded arch design allows the flange to be an integral part of the joint structure, providing stability and optimal expansion in neutral positions.

High-Pressure Capability: Designed to withstand high-pressure environments, making them suitable for critical applications.

Corrosion Resistance: Ideal for use in corrosive environments, these joints are often employed in industries like nuclear power, petrochemicals, and energy.

Customizable Sizes: They can be tailored to meet specific dimensional requirements, providing flexibility in installation.

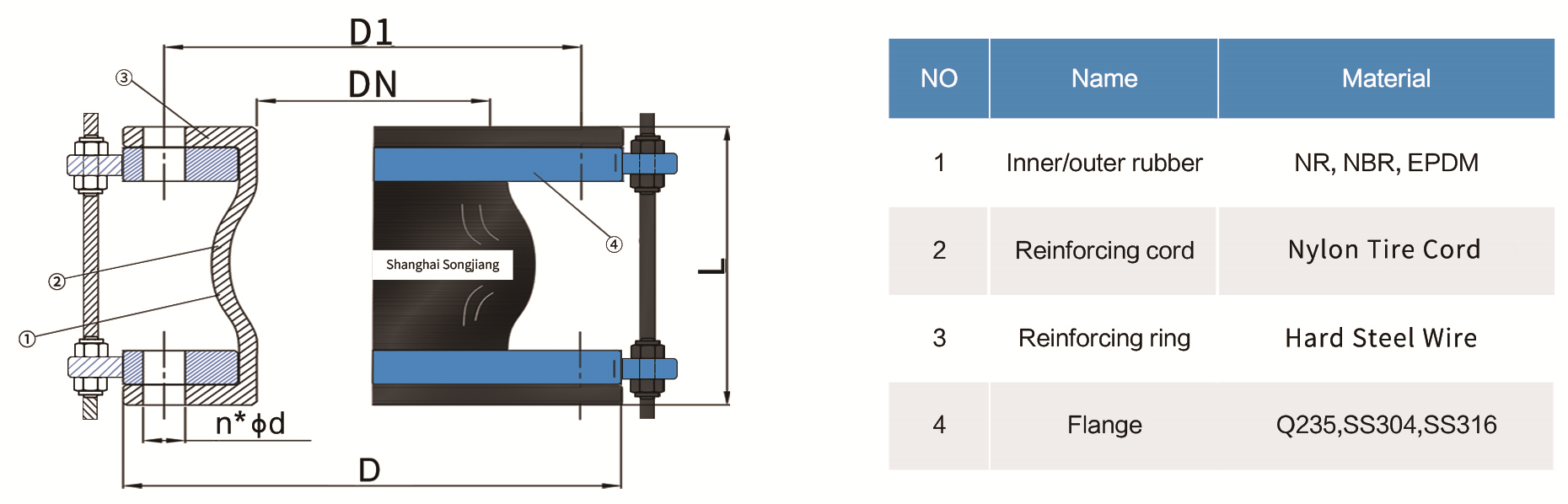

Internal Reinforcement Options: The option to add steel wire rings within the rubber bellows enhances pressure resistance and overall strength.

These features make KHD Hand-Wrapped Pipe Flexible Joints a reliable choice for various industrial applications that demand flexibility, durability, and resistance to extreme conditions.

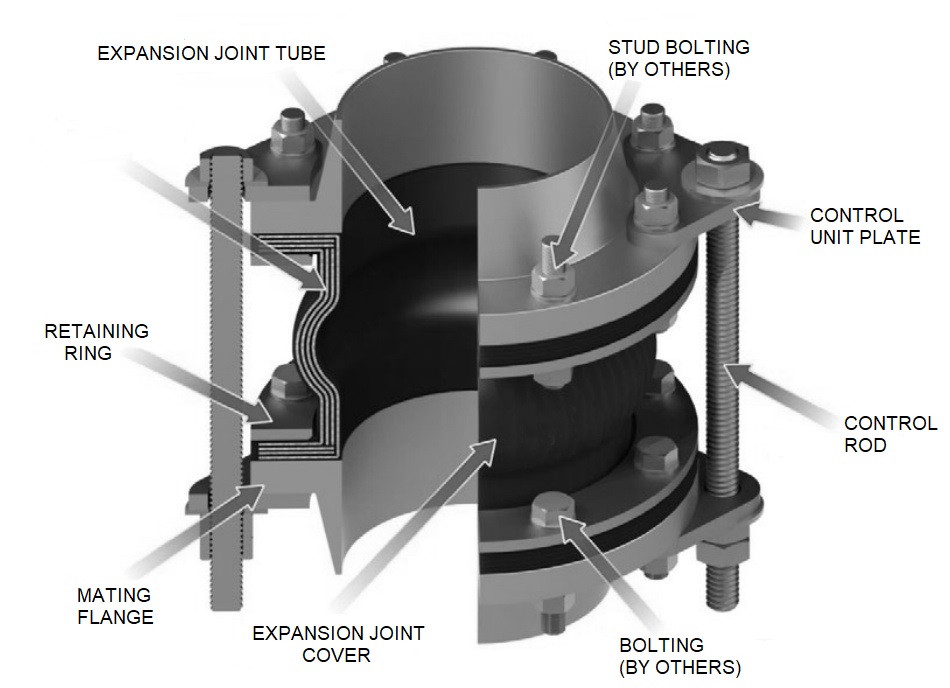

Designs

The installation diagram for the KHD hand-wrapped pipe flexible joints shows that when connecting to pipelines, it is important to align the flanges properly to avoid unnecessary stress. Use appropriate bolts and gaskets to secure the connection, and install the joint in a suitable location, avoiding interference with other equipment. For systems with pressure exceeding 1.6 MPa or pipe diameters larger than DN400, it is recommended to use a control system to manage and monitor the pressure, ensuring safe operation according to relevant safety standards.

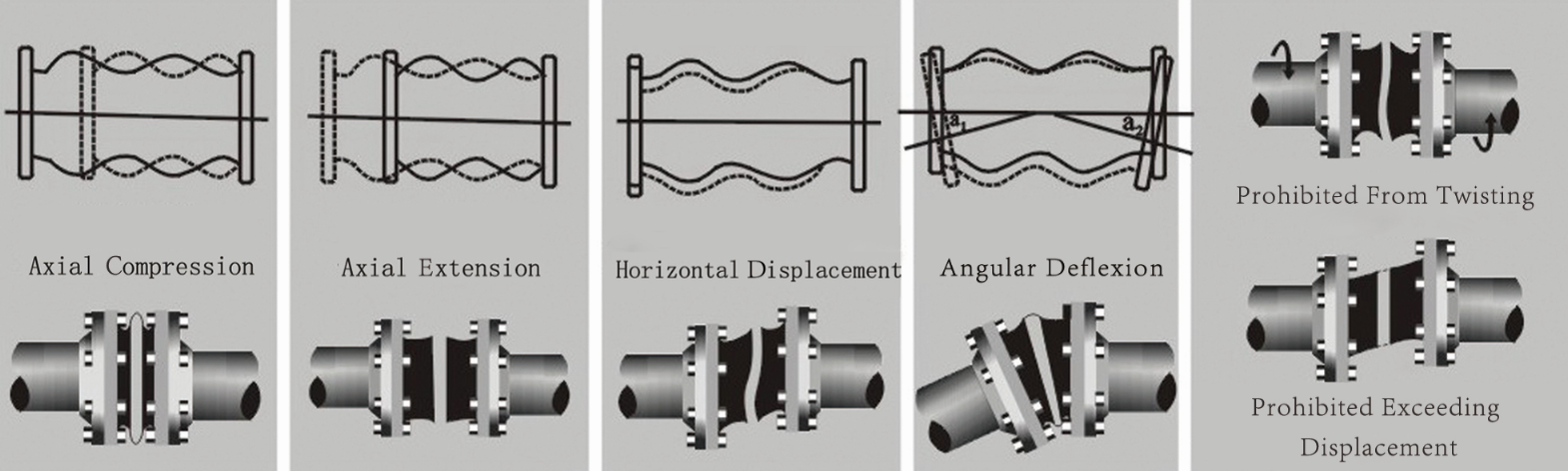

How does a rubber expansion joint displace?

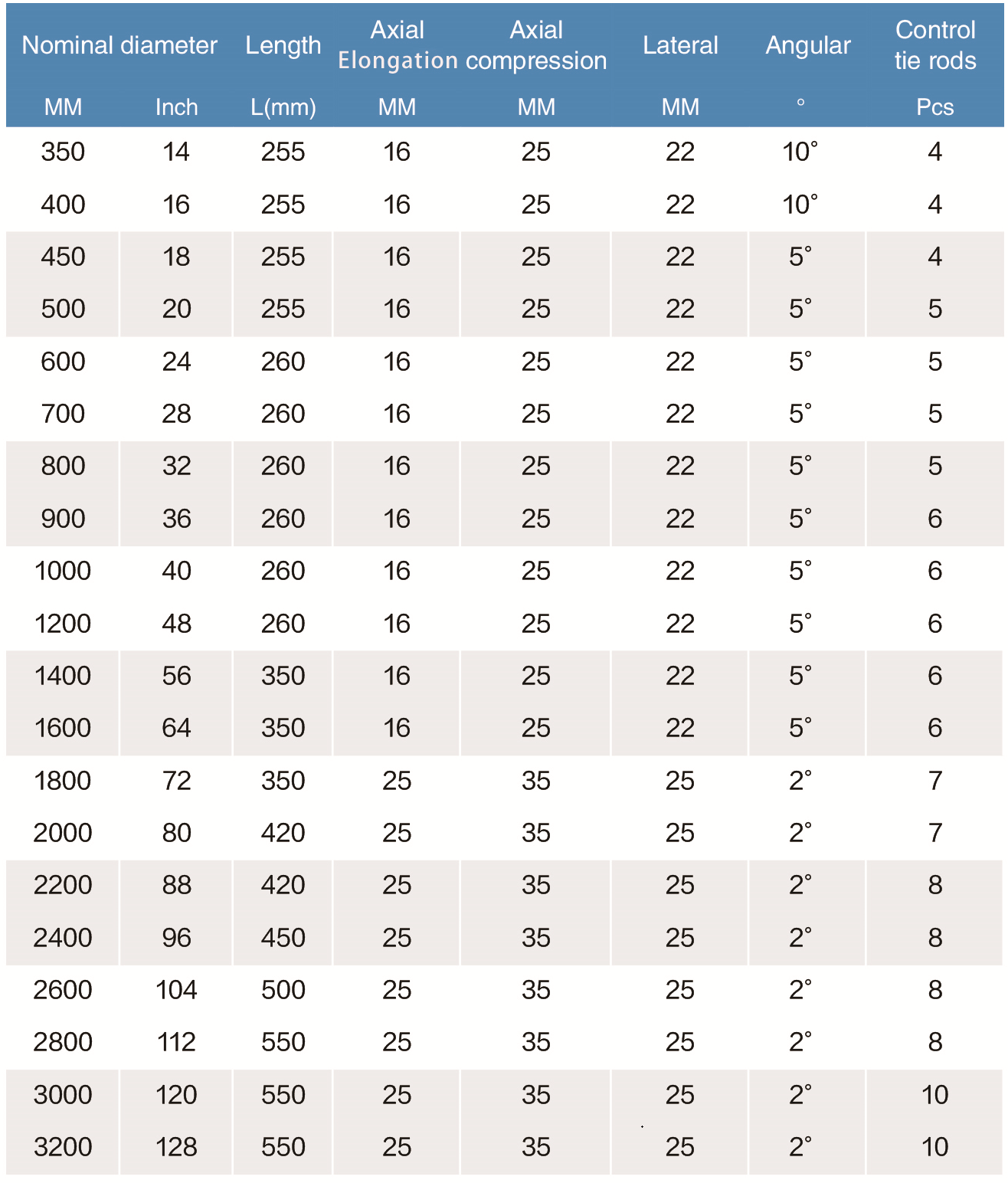

Data of Hand-built Wrapped Expansion Joint

Is the data for the above full faced rubber joint fixed? NO,You can customize it freely.

Customization Options for Flanges and Single Bellow:

Flange Material :

Cast Iron

Carbon Steel

Stainless Steel

Brass

Aluminum Alloy

PVC

Other materials

Standards for Flanges:

ANSI (American National)

DIN (German Standards)

JIS (Japanese Standards)

BS (British Standard)

Chemical Industry Standards

Marine Standards

Custom Non-Standard

Sphere Material :

NR (Natural Rubber)

NBR (Nitrile Butadiene )

EPDM

CR (Chloroprene)

FKM (Fluoro)

Silicone

PTFE Lining