ANSl Rubber Expansion Joints

The American standard flanged rubber expansion joints typically adhere to the following standards: ANSI/ASME B16.5: A standard for metal flanges, covering various types of flange dimensions and materials. ASTM D2000: A standard for the performance and specifications of rubber materials. Songjiang brand American standard rubber joints strictly comply with these standards to ensure product quality and reliability.

What is the molded ANSl rubber expansion joints?

The Molded single rubber expansion joint is mold-pressed single corrugation, also known as a bellow vibration isolator, pipeline compensator,rubber bellow, or flexible joint, is a type of pipe joint with high elasticity, airtightness,resistance to media, and weather resistance.lt has the following performance characteristics:

1、Small size, light weight, good elasticity, easy installation, and maintenance.

2、 During installation, it can generate lateral, axial, and angular displacement, without beinglimited by the misalignment of user pipelines or non-parallel flanges.

3、lt can reduce the transmission of structural noise and has strong vibration absorptioncapability.

4、Our internally developed seamless high-pressure flexible rubber joint effectively preventscorrosive media from eroding the inner wall of the flexible rubber joint in pipelines with hightemperature, acid and alkali resistance, and oil resistance, thereby improving its service life.

How does the ANSl rubber expansion joints work?

ANSI rubber expansion joints work by providing flexibility and movement in piping systems. They absorb thermal expansion, contraction, and vibrations, which helps protect the piping and connected equipment from damage. Here’s how they function:

Flexibility: The rubber material allows for axial compression, extension, lateral movement, and angular deflection, accommodating the movement caused by temperature changes and system pressures.

Vibration Dampening: The rubber absorbs vibrations generated by pumps, compressors, and other machinery, reducing noise and minimizing wear on the piping system.

Pressure Resistance: Designed to withstand various pressure conditions, ANSI rubber expansion joints maintain their integrity under high-pressure environments, ensuring safe operation.

Corrosion Resistance: The materials used are resistant to many chemicals, making them suitable for various applications in industries like chemical processing, HVAC, and oil and gas.

Easy Installation: ANSI rubber expansion joints can be easily installed without special tools, allowing for quick assembly and reducing downtime.

By effectively managing movement and vibrations, ANSI rubber expansion joints contribute to the overall reliability and longevity of piping systems.

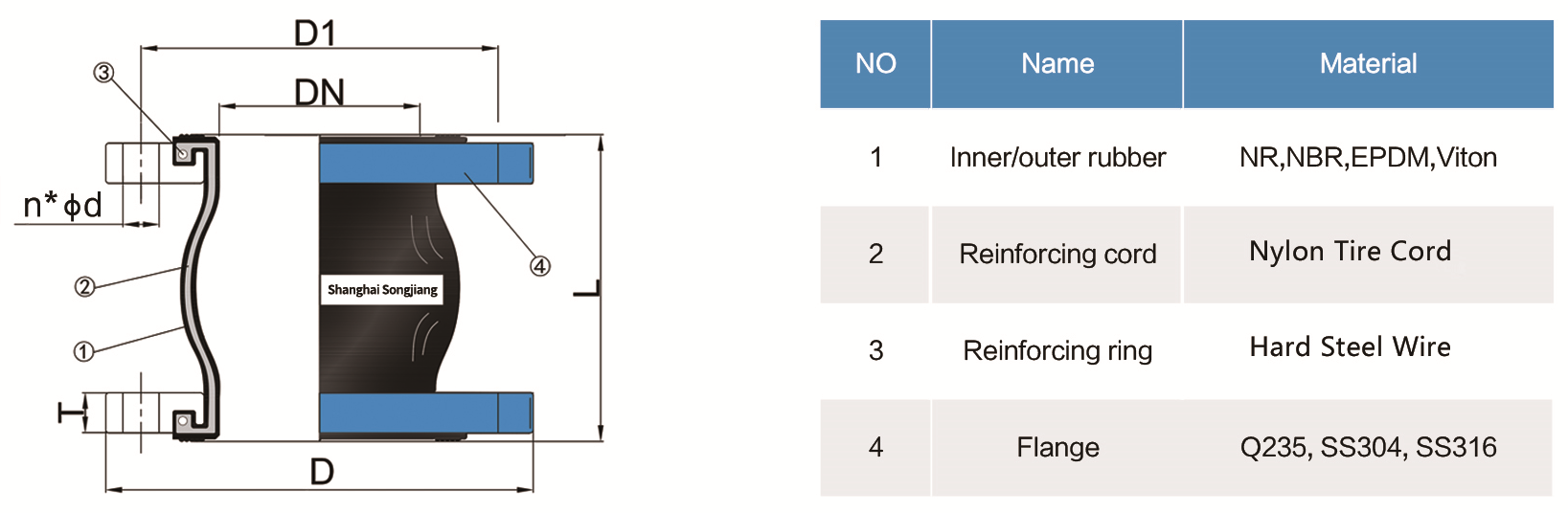

Designs

The ANSI rubber expansion joint primarily consists of two parts: the rubber body and the ANSI metal flange. The rubber body is typically divided into three layers: the inner rubber layer, the reinforcement layer, and the outer rubber layer. The standard lengths of the rubber body are usually 130mm, 150mm, and 200mm, and different rubber materials can be customized based on the type of medium being used. The flange can also be customized according to customer requirements in terms of standards and materials.

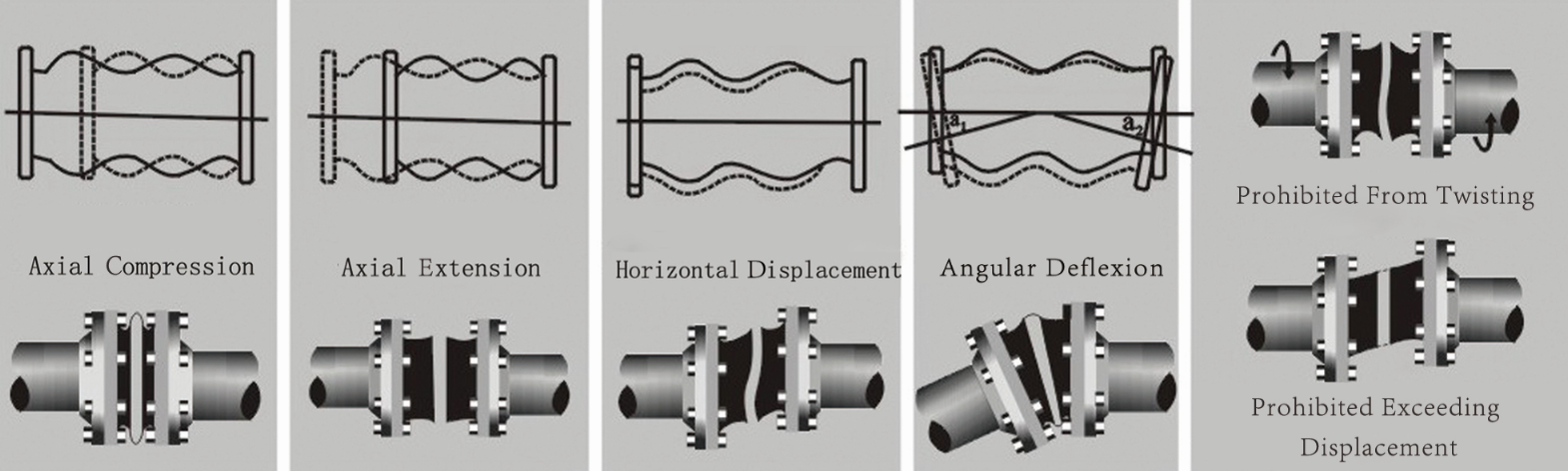

How does a rubber expansion joint displace?

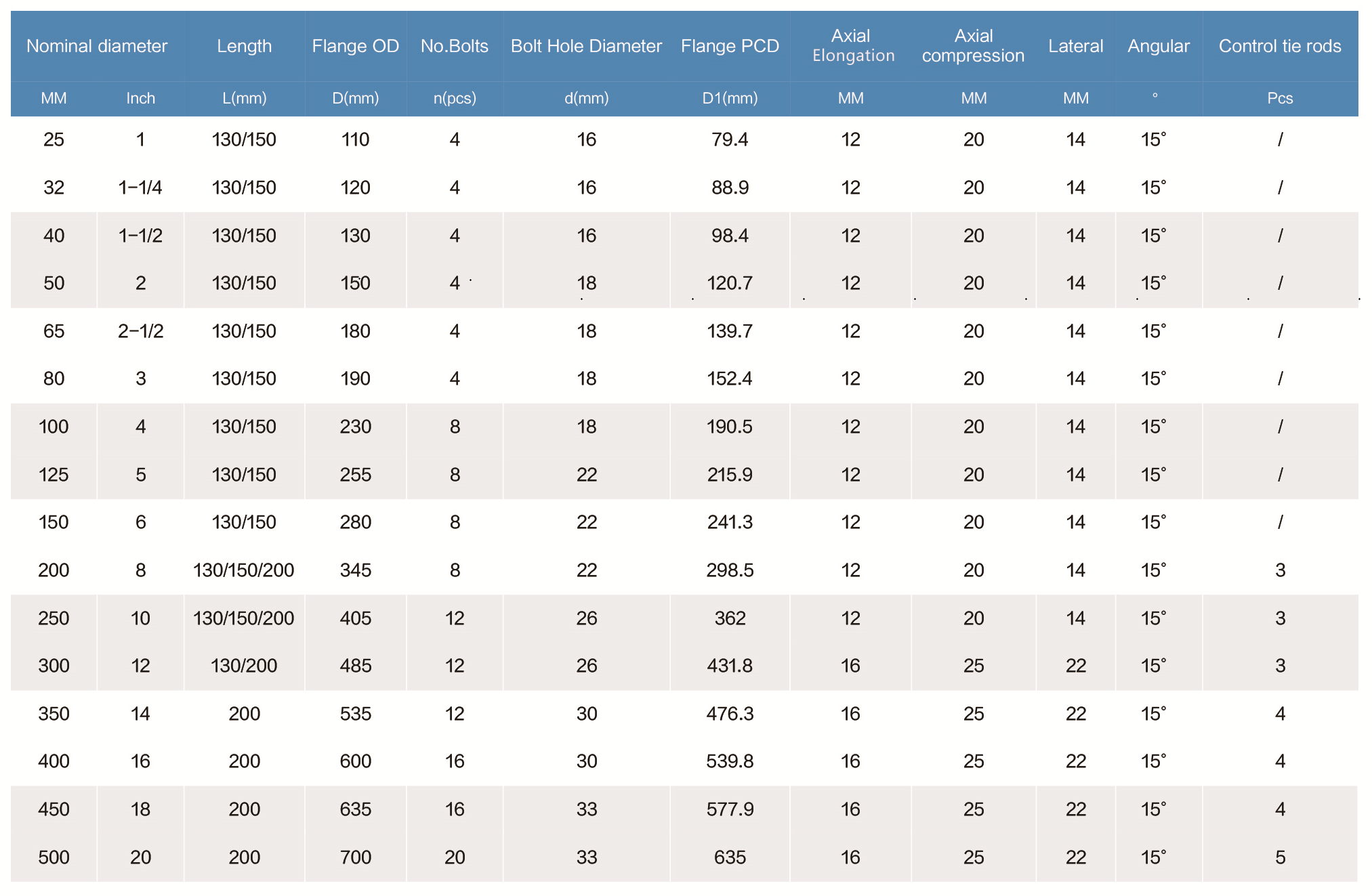

Data of molded ANSl rubber expansion joints

Is the data for the above ANSl rubber expansion joints fixed? NO,You can customize it freely.

Customization Options for Flanges and Single Bellow:

Flange Material :

Cast Iron

Carbon Steel

Stainless Steel

Brass

Aluminum Alloy

PVC

Other materials

Standards for Flanges:

ANSI (American National)

DIN (German Standards)

JIS (Japanese Standards)

BS (British Standard)

Chemical Industry Standards

Marine Standards

Custom Non-Standard

Sphere Material :

NR (Natural Rubber)

NBR (Nitrile Butadiene )

EPDM

CR (Chloroprene)

FKM (Fluoro)

Silicone

PTFE Lining