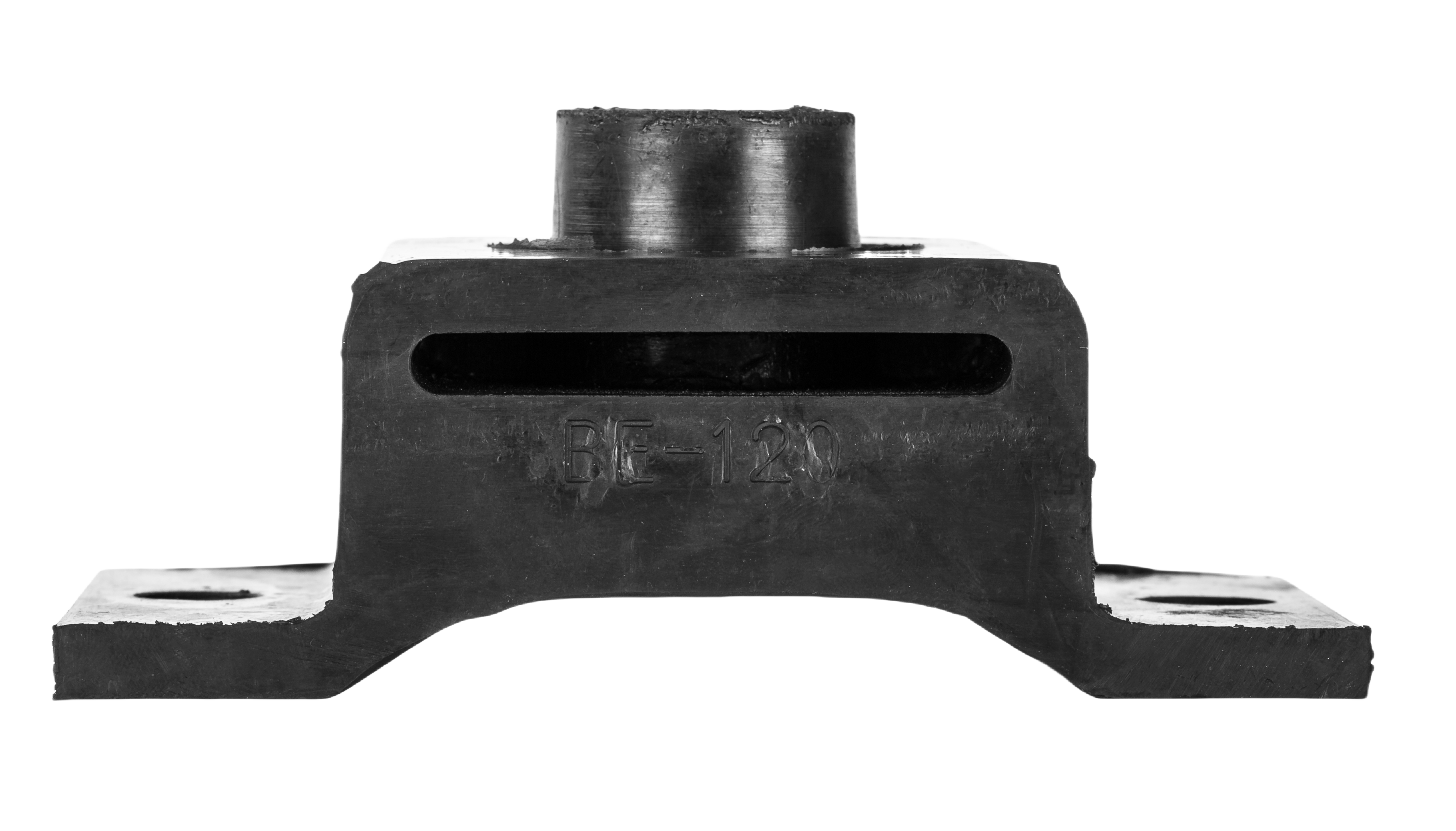

BE Type Rubber Isolator Mount

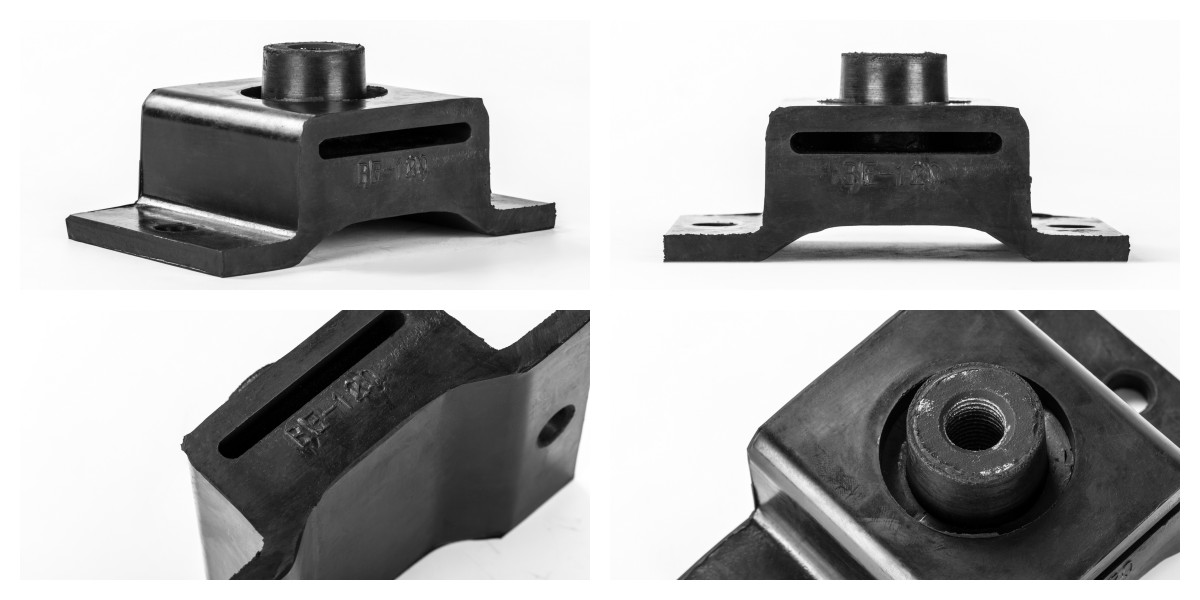

The BE-type rubber isolator is made of a metal and rubber composite, with the metal surface fully covered by rubber to prevent corrosion. The product is resistant to oil, seawater, salt spray, and sunlight, making it suitable for various environments, including land and marine applications. The product’s quality standards meet relevant U.S. military specifications.

What are the Unique Features of BE Rubber Isolator ?

1.Low Natural Frequency & Optimal Damping Ratio: The BE-type rubber vibration isolator has a low natural frequency and an optimal damping ratio, providing excellent vibration control.

2.Higher Lateral Stiffness: The lateral stiffness is higher than the vertical stiffness, making it suitable for various installation methods, such as horizontal, inverted, or side-mounted.

3.Good Lateral Stability: When installed horizontally, it offers strong lateral stability, ensuring smooth operation even under larger loa

4.Automatic Limiting Protection: Under heavy impact, the isolator automatically limits excessive movement, effectively protecting the equipment from damage while suppressing resonance peaks.

5.Rapid Dissipation of Self-Induced Vibrations: It efficiently reduces self-induced vibrations caused by overloading or shock responses, ensuring the equipment remains stable without noticeable shaking.

6.Wide Range of Vibration Isolation: The isolator provides significant vibration isolation over a wide range of interference frequencies, making it ideal for land and marine machinery such as diesel engines, fans, pumps, compressors, air conditioners, and precision instruments.

How does the BE Rubber Isolator work?

The BE-type vibration isolator utilizes a metal-rubber composite to absorb and dissipate vibrational energy effectively. Its low natural frequency and optimal damping ratio minimize vibration transmission, while higher lateral stiffness enhances stability in various installation positions. The isolator provides automatic limiting protection during heavy impacts and rapidly dissipates self-induced vibrations, ensuring smooth operation. Overall, it delivers significant vibration isolation across a wide frequency range for land and marine machinery.

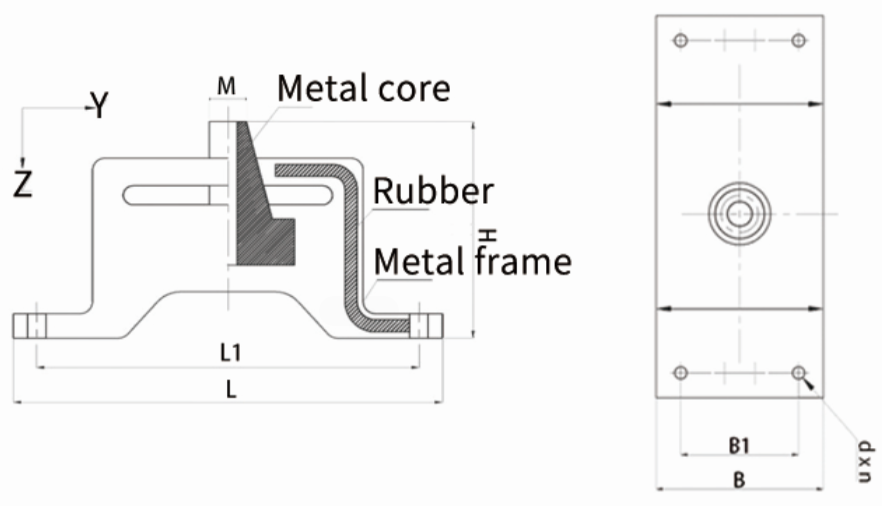

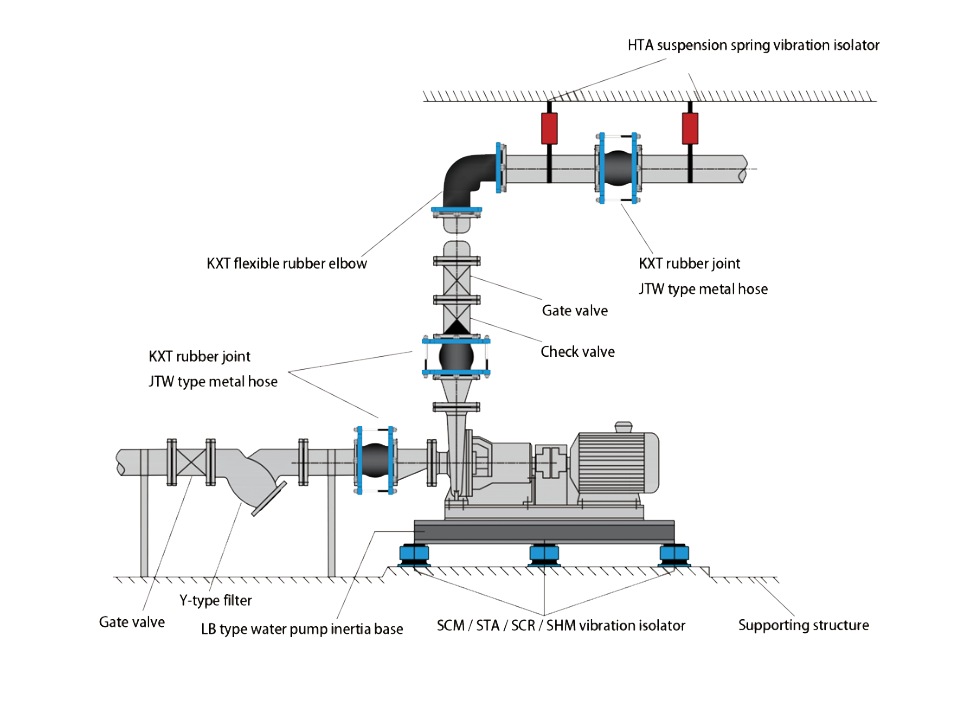

Diagram for vibration Isolator installation:

BE rubber vibration isolators are commonly used for pump isolation and offer several advantages: they provide excellent low-frequency vibration isolation due to large static deflection and low natural frequency, are resistant to corrosion from oil and water while remaining unaffected by temperature changes, and do not suffer from aging or creep deformation, ensuring long-term performance.

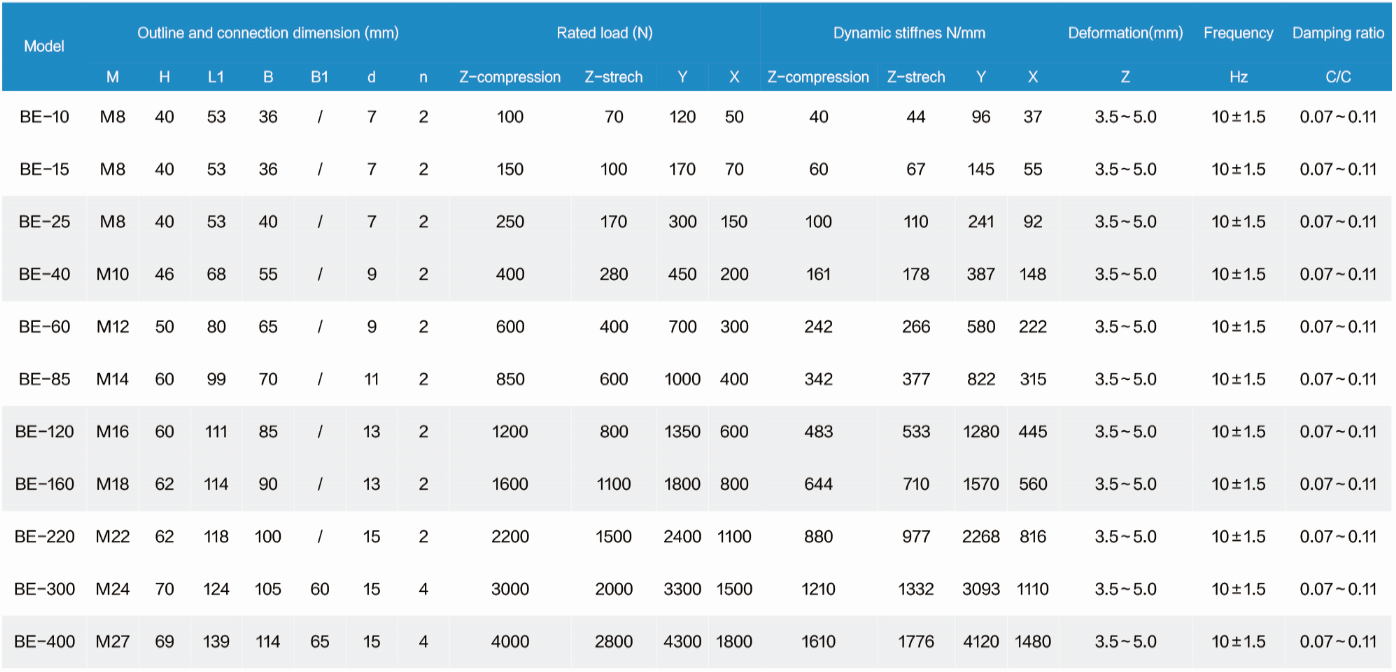

Data of BE Type Rubber Isolator Mount