JA Metal Shell Rubber Isolator

The JA-type rubber isolator achieves a high level of vibration reduction under both axial and lateral pressures, particularly effective for use in generators, engines, and systems, with excellent vibration isolation performance in an operational range of approximately 25 Hz (1,500 rpm). The internal rubber is fully bonded to the metal shell, providing the best vibration isolation. Additionally, it comes with safety lock components to ensure safety.

What are the Unique Features of JA Metal Rubber Isolator ?

1.Shell design with metal enclosure for enhanced safety.

2.Metal components with electroplating treatment for excellent weather resistance.

3.Effectively isolates vibrations and structural noise generated by machinery.

4. Main Applications: Various types of working machinery motors, engines, generators, transformers, and onboard electronic devices.

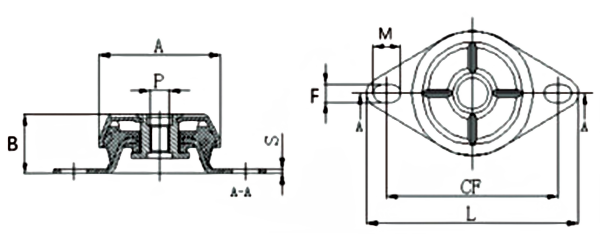

How does the JA Metal Shell Rubber Isolator work?

The working principle of the JA-type vibration isolator is based on the complete bonding of the internal rubber to the metal shell. This structure effectively absorbs and attenuates vibrations generated by machinery such as generators and engines. The isolator provides excellent vibration reduction under both axial and lateral pressures, increasing static deflection and lowering the natural frequency to reduce the transmission of vibrations to the equipment. Its design supports multidirectional forces and maintains stability under heavy loads, ensuring smooth and safe operation. Overall, the JA-type vibration isolator achieves effective vibration isolation and noise control through optimized materials and design.

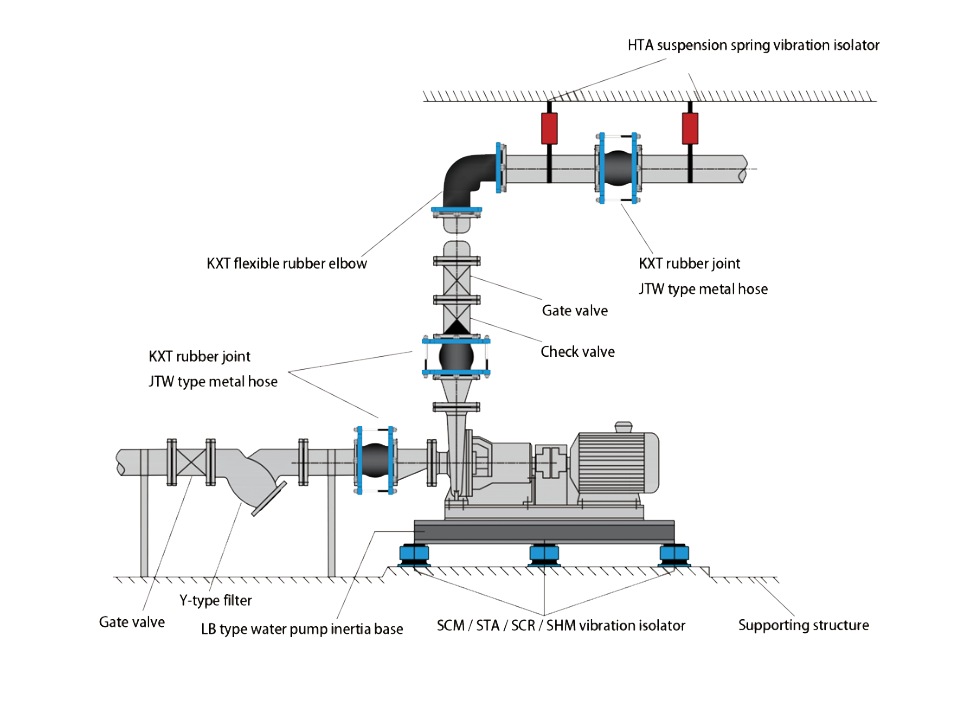

Diagram for vibration Isolator installation:

JA rubber vibration isolators are commonly used for pump isolation and offer several advantages: they provide excellent low-frequency vibration isolation due to large static deflection and low natural frequency, are resistant to corrosion from oil and water while remaining unaffected by temperature changes, and do not suffer from aging or creep deformation, ensuring long-term performance.

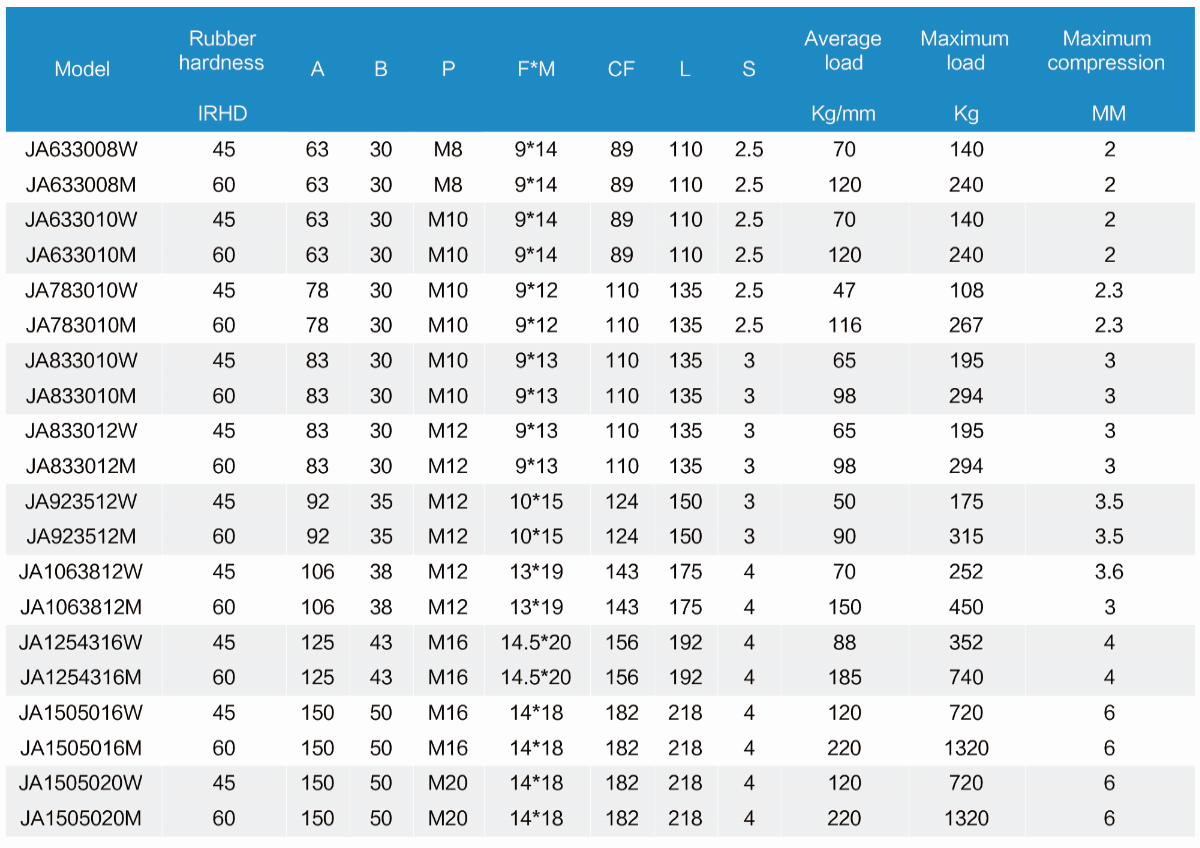

Data of JA Metal Shell Rubber Isolator