ZF Type Air Spring

The JBF rolled-edge rubber air spring is one of the most convenient and practical air springs. The upper and lower ports of the rolled-edge plate are sealed according to specific standards and dimensions, eliminating the need for users to install additional accessories such as flanges. It only requires connection to an air pump and pressure gauge for use. Rolled-edge rubber air springs are suitable for various types of machinery, cars, and buses.

What is the features of ZF Type Air Spring ?

1. Self-Sealing Mechanism: The self-sealing air spring operates without external force, utilizing internal pressure to maintain a tight seal, which minimizes air leakage and enhances reliability.

2. Reinforced Structure: The rubber bellows are reinforced with a fiber layer and incorporate a steel waist ring to prevent expansion during operation, ensuring stability and durability under load.

3. Effective Air Containment: The steel wire ring at the cover plate’s end deforms the rubber opening under air pressure, creating a secure contact between the upper and lower cover plates, which are zinc-coated for corrosion resistance.

4. Versatile Applications: These air springs are widely used in various manufacturing sectors, including electronics, communications, and automotive, making them suitable for stamping and forming processes across multiple industries.

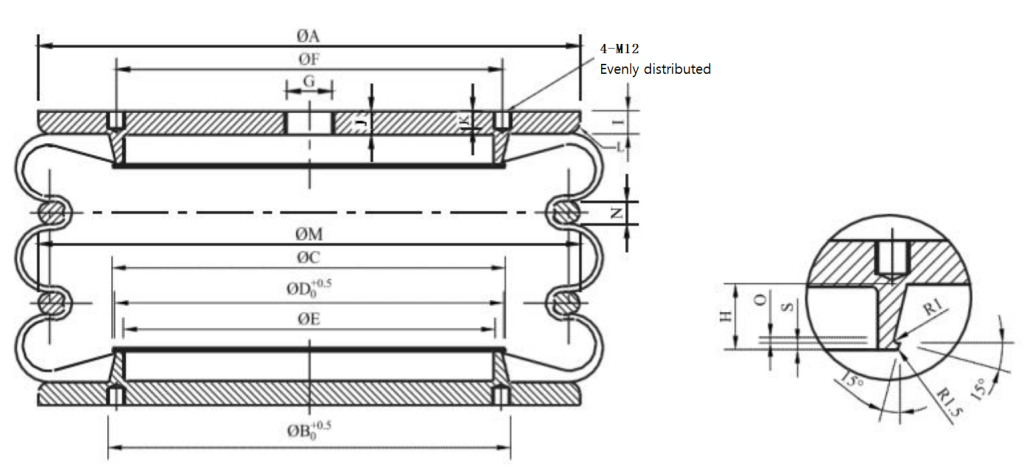

5. Precision Engineering: The components are precisely manufactured, with threaded air inlets for easy installation and standard threaded holes for versatile mounting options, ensuring ease of use in diverse applications.

How does the ZF Type Air Spring work?

The ZF Type Air Spring operates by using compressed air to provide flexible support for various loads, effectively isolating vibrations and shocks. Here’s a breakdown of its functionality:

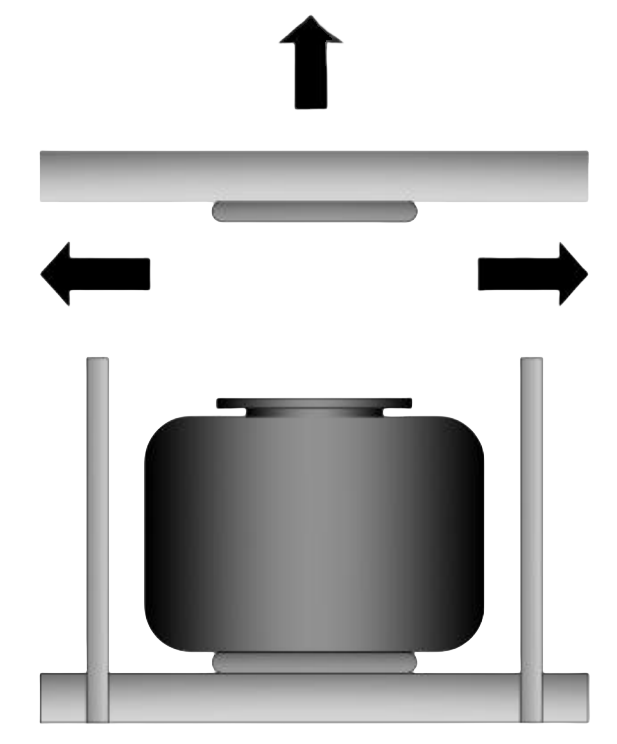

Structure: It consists of a flexible rubber envelope that holds compressed air. This envelope is designed to expand and contract as the load changes, allowing for adaptive support.

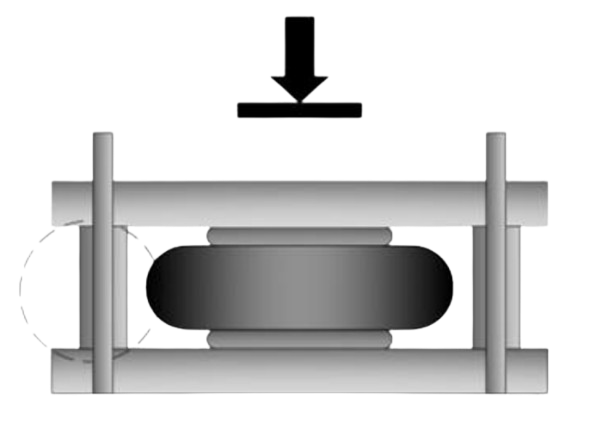

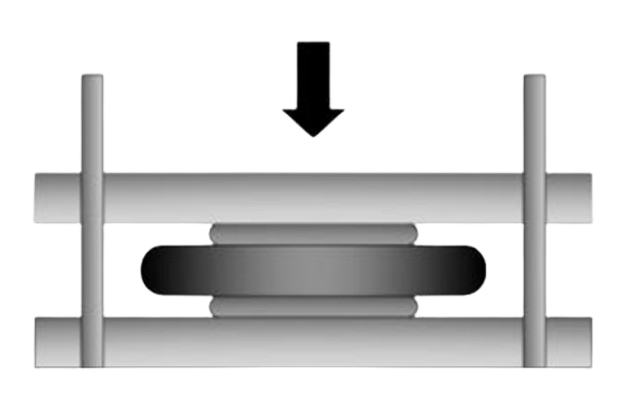

Air Pressure Regulation: The air pressure within the spring can be adjusted based on the load it needs to support. By increasing or decreasing the air pressure, the stiffness and height of the air spring can be modified, ensuring optimal performance.

Vibration Isolation: As the vehicle or machinery operates, the air spring absorbs shocks and vibrations. This is crucial in applications like vehicles, where smooth operation is essential for comfort and safety.

Load Distribution: The air spring evenly distributes the load across its surface, minimizing wear and tear on the surrounding components. This helps prolong the lifespan of the entire system.

Self-Leveling: Many ZF air springs are equipped with self-leveling features, automatically adjusting to changes in load to maintain a consistent ride height and performance.

In summary, the ZF Type Air Spring is a vital component for providing flexible, reliable support while enhancing comfort and performance through effective vibration isolation.

Precautions for Installing and Using Air Springs:

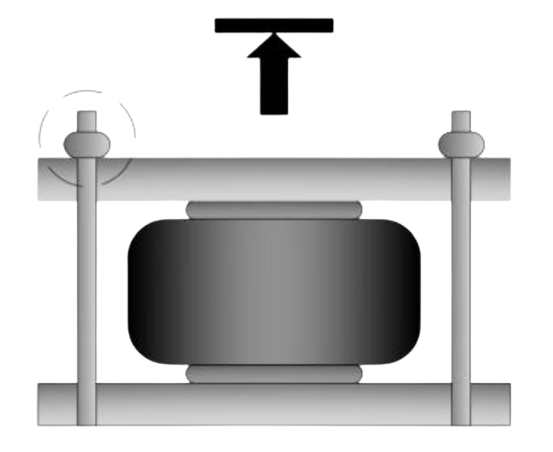

1.Do not exceed the recommended safe extended height when using air springs.

2. To extend the lifespan of the air spring, do not use the air spring below the minimum compressed height.

3. Do not use the air spring at a pressure exceeding 0.7 MPa.

4. Do not use the air spring in a twisted state.

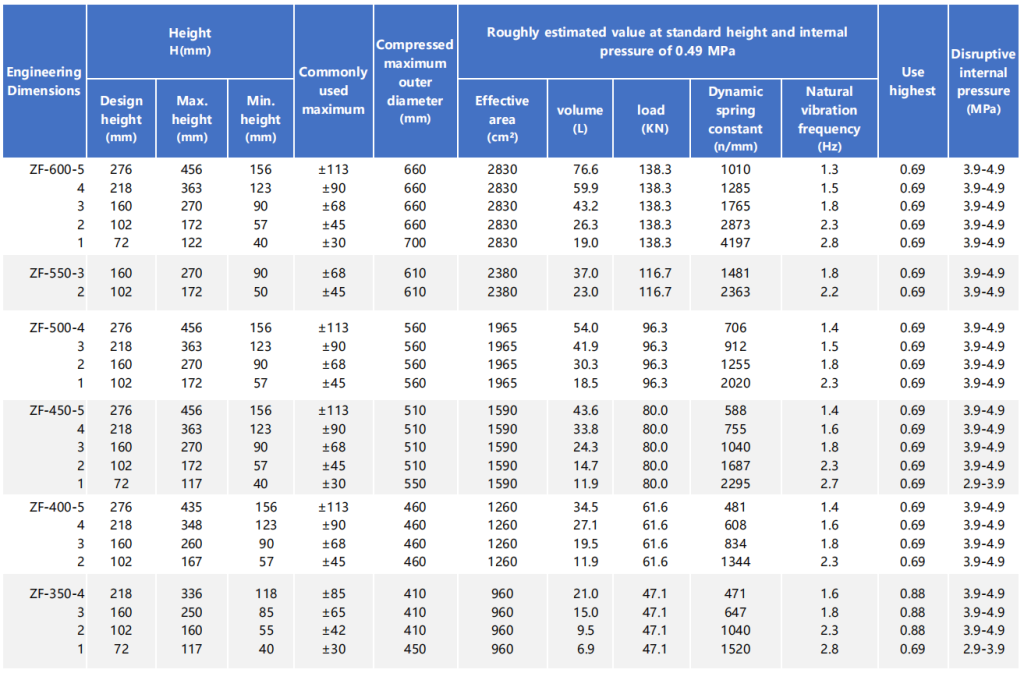

Model data for ZF Type Air Spring

We are a manufacturer specializing in the research and production of rubber air springs, with over 30 years of experience. Our products can serve as replacements for internationally renowned brands such as Firestone, Contitech, Dunlop (FR), Festo, Norgren, and Weforma.

Due to limited information available on our website, please email us at [email protected] for more detailed drawings and specifications of our air springs