EQUIPMENT MANUFACTURERS

In equipment manufacturing, rubber expansion joints must meet several requirements, including good chemical resistance, temperature tolerance, and pressure capacity to handle various media and extreme environments. Additionally, they should possess flexibility and reliable sealing performance to prevent fluid leakage, along with aging resistance to ensure stability during long-term use. The design should facilitate installation and comply with relevant industry standards to ensure their effectiveness and reliability in equipment, thereby enhancing the overall performance and safety of the system.

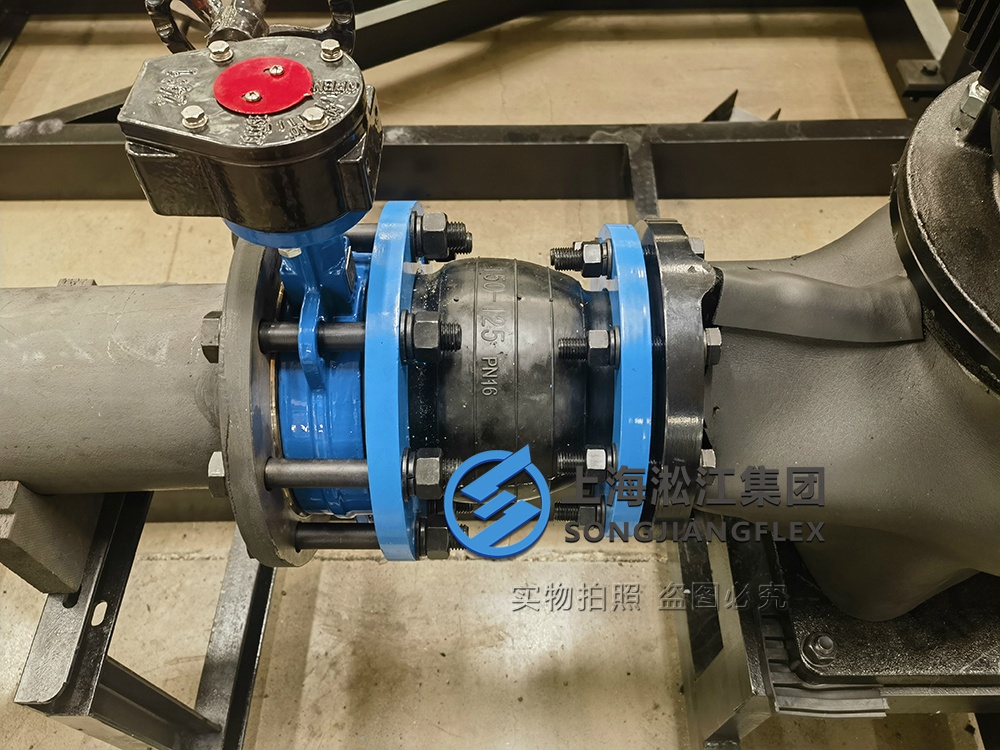

In the equipment manufactures industry, Songjiang rubber expansion joints and vibration isolators can provide high-quality solutions, as follows:

Rubber Expansion Joints Solution

-

Vibration Isolation: Rubber expansion joints help reduce vibrations caused by machinery operations, such as pumps, motors, and compressors. By isolating the vibration between connected parts, they protect sensitive equipment, prevent premature wear, and reduce noise in the surrounding environment.

-

Thermal Expansion Compensation: In systems that involve heated or cooled fluids, such as HVAC systems or industrial piping, rubber expansion joints absorb the thermal expansion and contraction of pipes. This prevents the pipes from bending or breaking due to temperature fluctuations and ensures the overall integrity of the system.

-

Pressure Fluctuations: Rubber expansion joints are used in equipment that experiences pressure variations, such as in fluid or gas systems. These joints help accommodate pressure surges, reducing stress on pipes and components, and ensuring smooth operation even under fluctuating pressures.

-

Leak Prevention: Rubber expansion joints are often used in fluid handling systems to create flexible seals between different sections of pipes, preventing leaks. Their ability to adapt to system movement ensures that the seals remain intact and reliable over time.

-

Connection of Dissimilar Materials: In systems where different materials are connected (e.g., metal to plastic), rubber expansion joints provide a flexible, durable interface that can handle different expansion rates and prevent stress at the junctions.

Vibration Isolators Solution

Vibration Isolation: Vibration isolators reduce the transmission of vibrations from equipment to the surrounding environment, decreasing the impact of vibrations on the ground, structures, and other equipment. This is especially critical for protecting sensitive equipment, such as precision instruments, machine tools, and CNC machines, where reducing vibrations helps maintain equipment accuracy.

Enhancing Equipment Stability: By isolating vibrations between mechanical components, vibration isolators help maintain the stability and alignment of equipment, preventing displacement, misalignment, or failure caused by vibrations. This is crucial for maintaining the precision of manufacturing processes and the long-term stability of the equipment.

BASF China is upgrading its production system with metal hoses, rubber expasion joints, and rubber /spring vibration isolators for a comprehensive overhaul.

Spring isolators for the Lubrizol specialty chemicals project in Shanghai, aimed at upgrading and retrofitting vibration control in the factory's chemical piping system.

Provide wear-resistant and oil-resistant rubber joints for the mud piping system of China Petroleum Corporation (CNPC) Chuanqing Drilling Engineering Company.

LG Chem's Guangzhou factory is undergoing a complete overhaul of its ducting system, utilizing corrosion-resistant isolators, which provide excellent vibration reduction.

Other Projects Involved by Songjiang - Reference List

-

The Anhui Tianshui Hydraulic Machine Tool Project uses our oil-resistant rubber joints, which are supplied to major hydraulic equipment manufacturers, primarily for the inlet and outlet of hydraulic pumps to reduce vibration and noise.

-

Our company supplies hydraulic rubber shock-absorbing hoses for numerous shield machines and tunneling machines, including the NG rubber shock-absorbing hose used in the XCMG Kaigong Heavy Industry Shield Machine Project, which is produced by our factory.

-

The double-ball oil-resistant rubber joints used in the Xiangyang Shiruida Heavy Industry Project are produced by our company, utilizing carbon steel flanges and oil-resistant rubber specifically for hydraulic oil.

-

The Zhongji Forging Jiangsu Co., Ltd. Project uses oil-resistant rubber expansion joints. Zhongji Forging’s main business includes forging machinery, sheet metal machinery, and pile-driving machinery.

-

We provide high-quality rubber expansion joints for machine tool construction projects in various cities, made from pure natural rubber with no recycled rubber, including the Jinan No. 2 Machine Tool Equipment Project.

-

Our company supplies rubber air bags for paper machines in paper mills, such as the rubber air bags used in the Jiangsu Kaisheng Paper Industry Paper Machine Roller.

-

Our company won the bid for the Changsha Metro Equipment Project in 2015, which utilizes rubber joints produced by our factory. We also supply rubber joints for other metro projects.

-

The Sichuan Panzhihua Steel City Group Co., Ltd. Ruifeng Refrigeration Equipment Co., Ltd. uses rubber expansion joints supplied by our company, with carbon steel flanges and natural rubber.

-

Our company provides high-quality rubber expansion joints for numerous semiconductor companies, including the rubber expansion joints used in the SK Hynix Semiconductor (Chongqing) Co., Ltd. Chongqing Hynix Project.

-

The Chinese Tracked Amphibious Armored Vehicle Project uses rubber expansion joints manufactured with high standards by our factory, made from ethylene propylene diene monomer (EPDM) rubber, with stainless steel flanges.