Vibration Isolators ,Seismic Mounts ,Air Springs

Looking for high-quality vibration isolators? Explore our exceptional range of spring and rubber vibration isolators. Shift from settling for less to embracing unparalleled reliability. Enhance the lifespan of your equipment and expand your business with our isolators. Connect with us today and redefine quality!

More Than Just a Vibration Isolator Supplier

In Songjiang Group, we take pride in being more than just an ordinary vibration isolator supplier with over 30 years of experience. Our commitment to excellence, combined with advanced manufacturing technology and an experienced team, sets us apart in the vibration isolator industry. Please explore our core services.

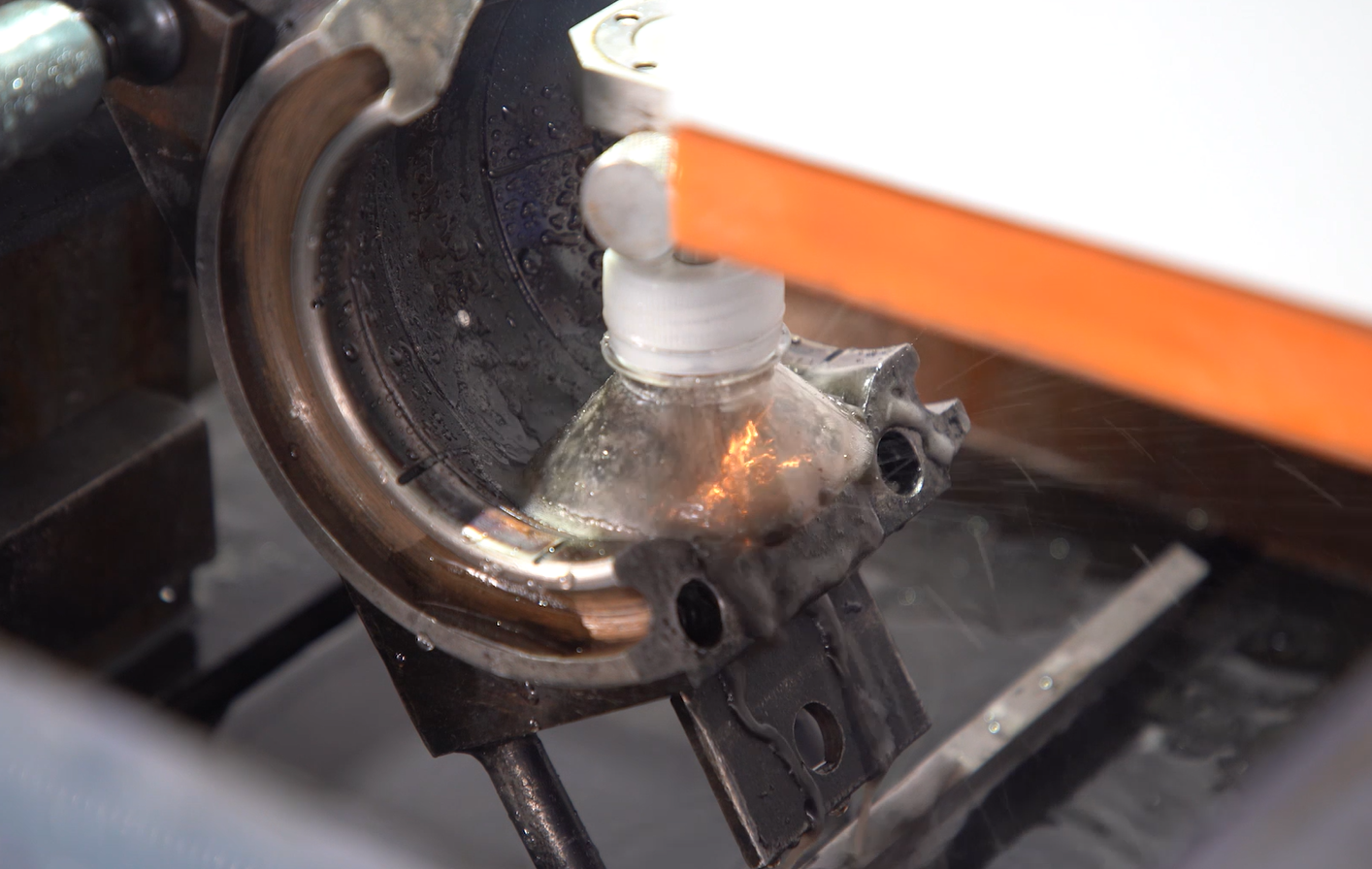

Precision Manufacturing

Utilizing advanced machinery and technology, we ensure that each product meets stringent quality and craftsmanship standards

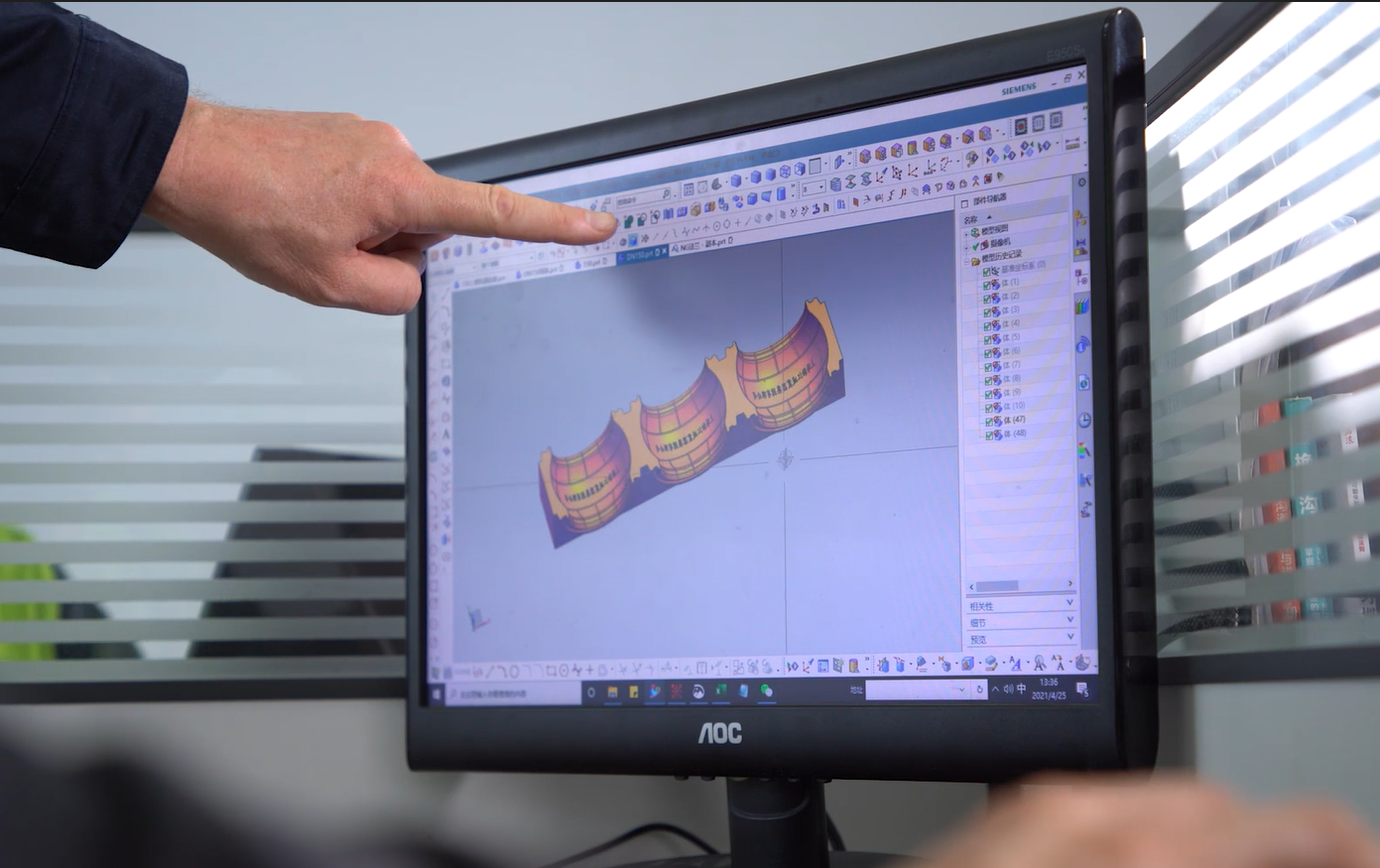

Custom design machining

Our expertise includes free design and custom manufacturing services. Whether you provide an idea or a drawing, we can design a solution according to your requirements.

Advanced materials

Through our high-precision machining and advanced materials, we transform raw materials into high-quality vibration reduction products suitable for a variety of applications.

Comprehensive Service

Our experienced team works closely with you, providing insights and guidance throughout the manufacturing process to achieve optimal results, while ensuring worry-free after-sales support.

Vibration Control Solutions: Tailored for Every Step of the Supply Chain

With our specialized solutions in vibration control and extensive product knowledge, we are fully equipped to tackle the unique challenges at every stage of the supply chain, helping your business thrive in a highly competitive market. Our commitment to innovation and quality ensures that you receive the best possible outcomes tailored to your specific needs.

Wholesalers: Wholesalers require substantial inventory, competitive pricing, and consistent quality. Leveraging our extensive resources and top-notch production capabilities, we offer premium vibration isolators at market-friendly prices.

Contractors: Contractors encounter unique project requirements and tight schedules. We provide complimentary customized solutions and flexible manufacturing to ensure the success of every project.

Brand Stewards: Brand leaders seek unique products, consistent branding, and high standards. Our expert teams deliver OEM vibration control products that maintain brand integrity and quality, safeguarding your brand image.

Distributors: Distributors value stable inventory, a diverse range of vibration products, and speed. Our extensive selection of isolators and strong logistics network guarantee prompt and reliable shipments.

what is vibration isolator?

A vibration isolator is a device designed to reduce or control vibrations and shocks, widely utilized in mechanical, construction, and automotive applications. It functions by absorbing, isolating, or dissipating vibrational energy, thereby protecting equipment and structures, extending their lifespan, and enhancing operational safety and comfort. Typically, vibration isolators employ springs, dampers, or other materials, leveraging their physical properties to effectively attenuate vibration propagation. The design and selection of these isolators depend on specific application requirements to ensure optimal performance.

What types and functions do vibration isolators have?

Vibration isolators come in various types, each serving different functions. Common types include:Spring Isolators,Rubber Isolators,Air Dampers,Wire Rope Isolators,Rubber Air Springs,Rubber Expansion joints .

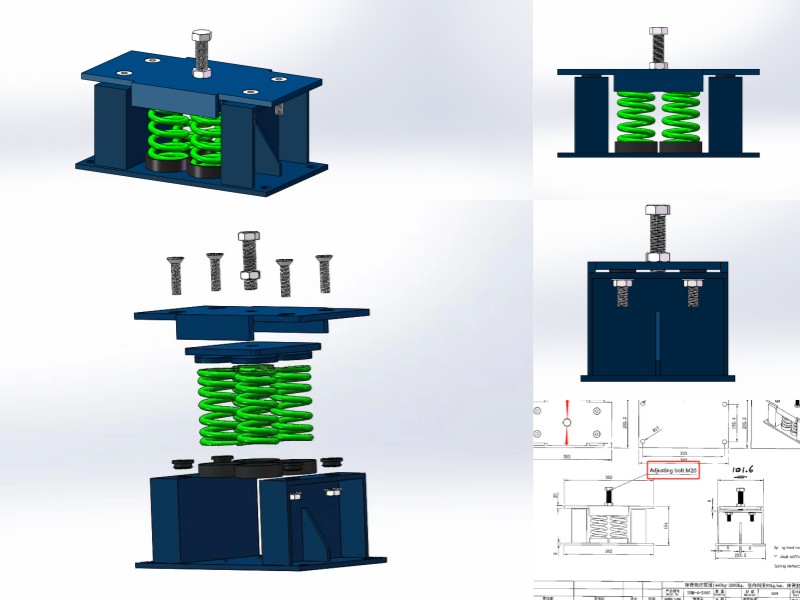

Spring Isolators

Utilizing the elasticity of springs to absorb vibrations is widely used in various HVAC mechanical devices.

Rubber Isolators

Use rubber materials to effectively isolate low-frequency vibrations, commonly found in buildings and equipment.

Air Dampers

Using air for vibration isolation offers high efficiency, with typical equipment achieving over 97% in vibration reduction.

Wire Rope Isolators

Multidirectional wire rope isolators provide protection against harsh shock and vibration during transport and handling of HVAC sensitive equipment.

Rubber Air Springs

Air springs work by using a sealed air chamber for elastic support. Adjusting the pressure inside the chamber effectively absorbs vibrations and shocks.

Rubber Expansion joints

Flexible compensators for displacements in all directions, reducing stress and vibrations on the piping system while protecting system equipment.

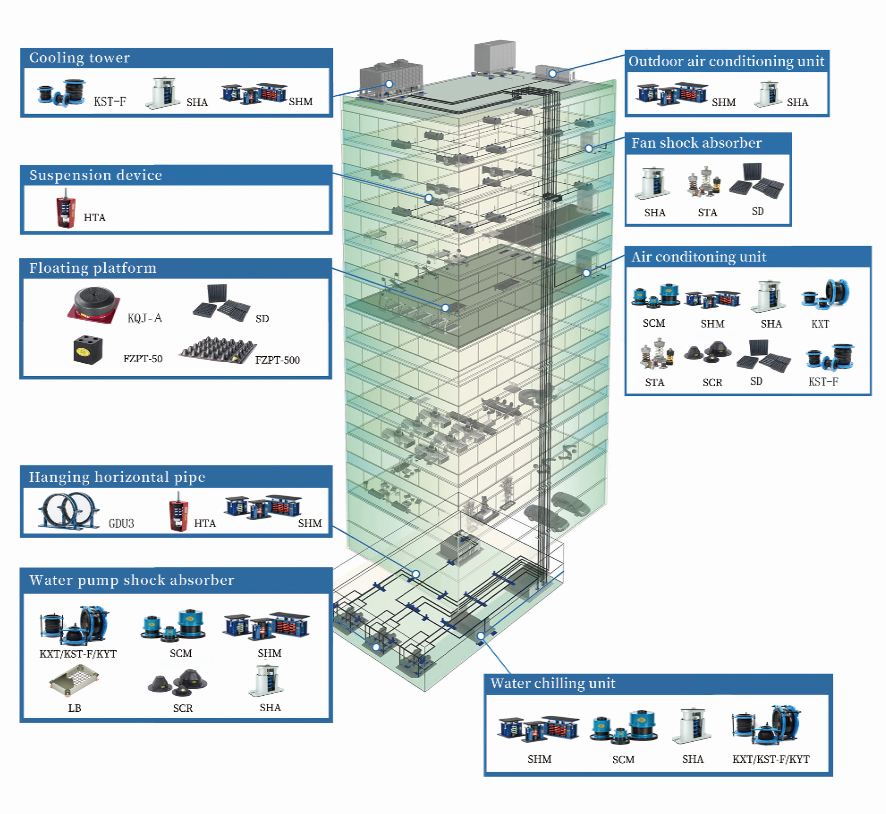

How are isolators applied in high-rise buildings?

Vibration isolators in high-rise buildings are commonly used for rooftop or underground mechanical equipment, such as HVAC systems, generators, or water pumps. These devices help reduce the transmission of vibrations from the equipment to the building structure, enhancing operational efficiency and minimizing noise and structural stress. This application is crucial for ensuring the stability, comfort, and longevity of the building by managing vibrations effectively in critical areas.

How to choose the right vibration isolator Supplier?

Choosing the right vibration isolator supplier or manufacturer is crucial for project success. Key factors include:

Why should pumps be equipped with vibration isolators?

Importance of Vibration Isolation in Water Pumps

As urban construction increasingly favors high-rise buildings, water pumps in pressurized systems for HVAC and domestic water use have become widespread. However, these pumps bring challenges like vibration and noise that affect structural stability and equipment longevity. The main causes can be categorized into four areas:

1. Electrical: Imbalances in the motor’s magnetic force or electrical system cause noise and vibration.

2. Mechanical: Issues such as poor alignment, imbalance, and worn parts lead to mechanical vibrations.

3. Hydraulic: Unsteady flow, pressure pulsations, and water hammer cause pump-induced vibrations.

4. Hydraulic Structures: Inadequate intake design, submerged pump depth, and foundation instability worsen vibration.

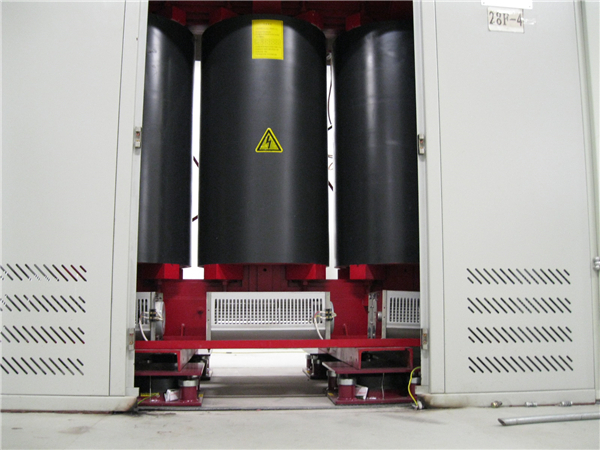

Given the inevitability of some vibration sources, installing inertia bases with spring or rubber vibration isolators beneath pumps is a crucial method for isolating and controlling vibrations. This helps protect both the equipment and the building structure from prolonged damage, ensuring safer and more efficient operation.

In which industries are vibration isolators used?

Vibration isolators are essential components used to minimize vibration and noise in various industries. They find applications in industrial machinery, automotive systems, HVAC in construction, railway and aerospace sectors, as well as household appliances and marine engineering. Their versatility and effectiveness in controlling mechanical vibrations enhance equipment longevity and improve operational stability across these fields. If you need more details or specific examples, feel free to ask!

Spring isolators are widely used in HVAC systems(Heating, Ventilation, and Air Conditioning).

Rubber isolators are widely used in generators, compressors, pumps, and fans machines.

Air isolators are used in CNC semiconductor manufacturing equipment, precision devices, and instruments.

Wire rope isolators are used in aviation equipment, communication devices, and precision electronic instruments.

Air springs are used in automobiles, industrial machinery, and precision equipment.

Rubber expansion joints are used in various piping systems for water, oil, natural gas, and chemicals.

How to select a vibration isolator and calculate effectiveness?

Steps for Selecting a Vibration Isolator and Calculating Effectiveness

1. Identify the Application

Clearly define the specific use case for the isolator, such as the type of machinery, environmental conditions, and operational requirements.

2. Determine Load Requirements

Calculate the weight and dynamic load of the machinery that the isolator will support.

3. Select Vibration Frequency

Measure the operational frequency of the equipment to understand its vibration characteristics.

4. Choose Material Type

Select the isolator material (e.g., rubber, air, or metal) based on its properties, durability, and compatibility with the environment.

5. Calculate Isolator Performance

Use formulas to assess the performance of the isolator, focusing on factors like natural frequency and damping ratio. The effectiveness of the isolator can often be expressed in terms of the reduction ratio, calculated using the equation:

R = Fout / Fin

where Fin is the input force and Fout is the output force after isolation.

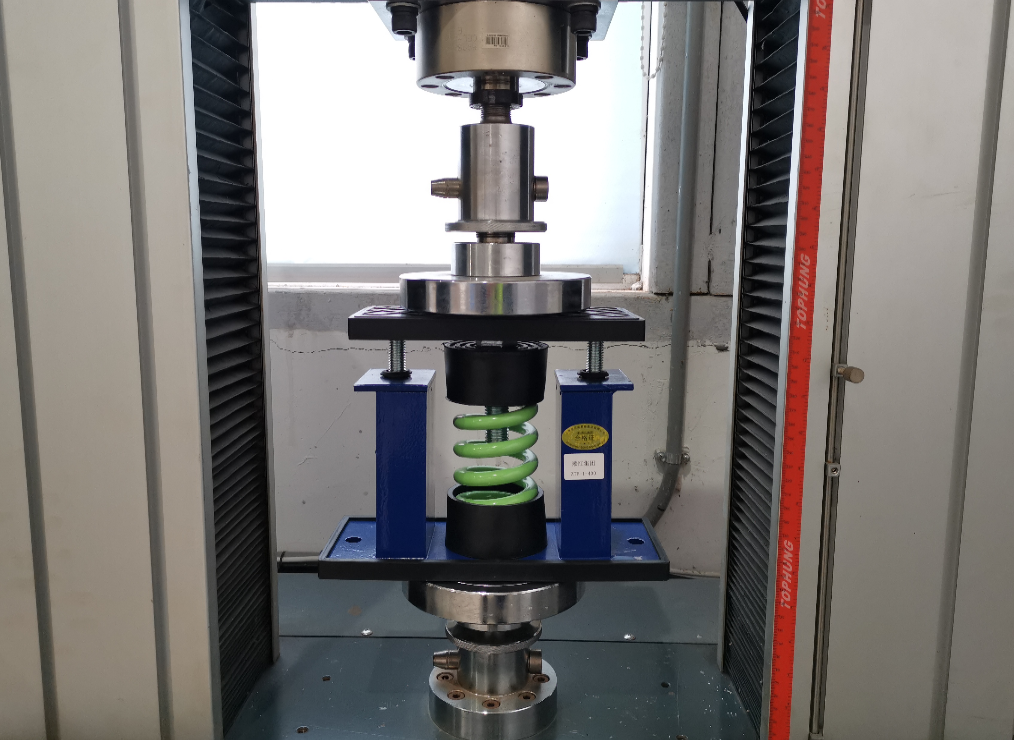

6. Testing and Validation

After installation, conduct vibration tests to confirm the isolator’s performance and make adjustments as necessary.

What should consider when buying vibration isolators?

Application Scenario: The intended use of the isolator will directly influence its selection. For instance, the requirements in the automotive industry, construction sector, and industrial equipment can vary significantly. Therefore, identifying the specific application of the isolator is crucial.

Load Capacity: The load capacity of the isolator must match the weight of the equipment or structure it supports. It’s essential to ensure that the isolator can handle the expected load and provide adequate support to prevent damage or failure.

Frequency Response: Different designs of isolators exhibit varying frequency responses. Selecting an appropriate isolator based on the vibration frequency of the equipment is important for optimizing performance and effectiveness.

Material Selection: The material used in the isolator affects its durability and performance. Common materials include rubber, metal, and air, each with distinct physical properties suitable for different applications.

Installation Method: The method of installation for the isolator should also be considered. Choosing the right installation method according to the equipment’s design ensures the effectiveness and stability of the isolator.

Cost and Budget: Finally, it’s important to consider the cost and budget for the isolator. While high-quality isolators may require a higher initial investment, they could save costs on maintenance and replacements in the long run.

Frequently Asked Questions

Can’t find the answer you’re looking for? Reach out to our customer support team.