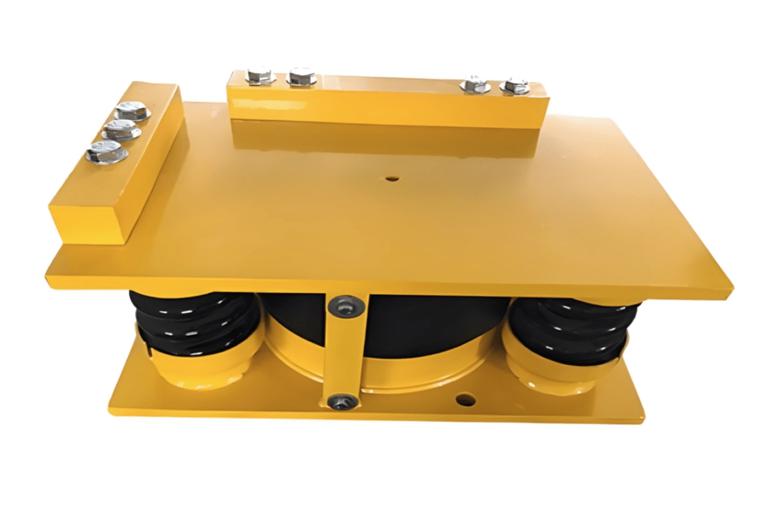

Damping Spring Vibration Isolator

Our company manufactures damping spring vibration isolators, which combine the elasticity of springs with the energy absorption characteristics of dampers. These isolators are widely used in industries such as machinery, construction, and transportation. They effectively reduce equipment vibrations, improve operational stability, and extend the service life of equipment. By isolating and absorbing vibrations, the product helps reduce noise and improve the working environment. We offer a variety of models to meet the needs of different applications.

Textile machinery vibration isolators are used to reduce vibrations in textile production, enhancing equipment stability and improving production efficiency. At the same time, they effectively reduce noise and extend the lifespan of the equipment.

The vibration isolators for centrifuges and presses are designed to minimize vibrations during high-speed and heavy-load operations. They help improve equipment stability, reduce noise levels, and contribute to extending the lifespan of the machinery.

The vibration isolators for hammers are designed to minimize vibrations and shocks, enhancing equipment stability, safety, and longevity. They absorb impacts through the use of rubber, metal springs, or composite materials.

The vibration isolators for roller mills are designed to reduce vibrations during the operation of grinding machines, precise grinding processes. They effectively protect the equipment, enhance processing accuracy.

Vibration isolators for printing and packaging machinery minimize vibrations, enhance machine stability and print accuracy, and prolong the lifespan of the equipment.

Vibration isolators for crushers and coal mills are designed to absorb and reduce vibrations generated during crushing and grinding processes.

Vibration isolators for high-speed punching machines are built to minimize vibrations during high-frequency stamping processes, improving machine stability and performance by absorbing shocks.

Vibration isolators for air handling units and generators are engineered to minimize vibrations during operation. They enhance system stability, contributing to extended lifespan and more efficient performance.

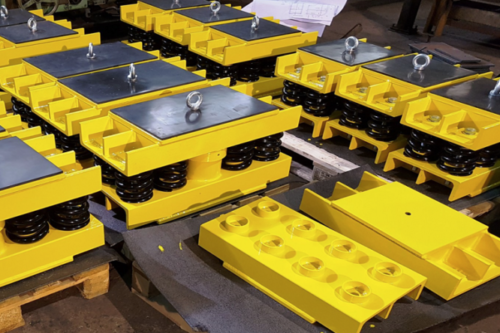

Customized Hydraulic Damping Vibration Isolator

We offer customized hydraulic damping vibration isolators according to your provided samples or technical drawings.

Additionally, we provide complete vibration isolation design solutions for a wide range of machines and equipment.

Raw Materials

Production process

Testing Center

After-Sales Service

We offer a 5-year warranty for standard products and a 3-year warranty for products used in special environments. In the event of any quality issues, we commit to providing a solution within 24 hours. If the issue is confirmed, our factory will replace the product free of charge.