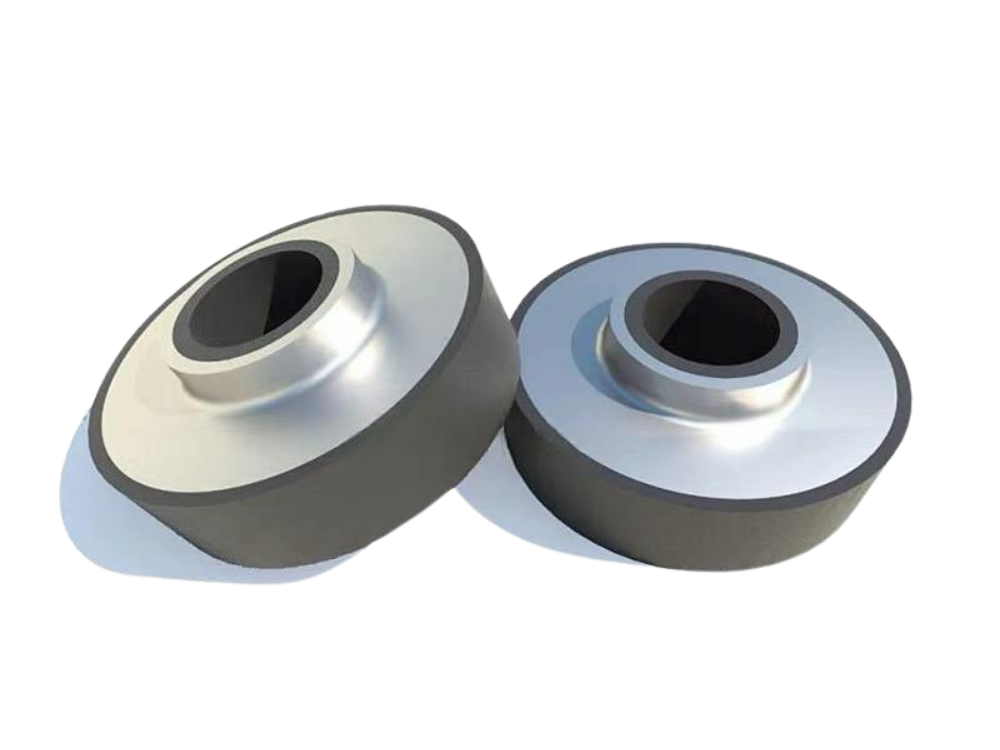

Center Bonded Mounts

Center bonded mounts are compact rubber isolators with rubber bonded between inner andouter metal parts. They effectively absorb both axial and radial vibrations, ensuring equipmentstability and protection. These mounts are widely used in engines, compressors, and HVACsystems. Key benefits include strong vibration isolation, easy installation, and resistance to oiland aging. Their space-saving design and customizable options make them ideal fordemanding industrial and mobile applications.

CN Cone Mounts are high-load, low-cost vibration isolators with a compact design. They are ideal for engines, radiators, and vehicle body parts, offering effective multi-axis vibration isolation even under uneven loading conditions.

Rubber-metal ring buffers are elastic spring elements for light to medium loads, usually installed in preloaded pairs. They reduce structure-borne noise and vibrations, suitable for seats, cab mountings, pipes, and control cabinets.

The ST stepper motor damper is made of high-strength NBR rubber, offering excellent vibration and noise reduction. It’s heat-resistant, durable, and easy to install, widely used in 3D printers, CNC machines, and robots.

A7 suspension stabilizer bar bushings absorb and cushion vibrations using elastic rubber, protecting equipment and extending service life. Designed with abrasion- and aging-resistant rubber and galvanized metal brackets, they provide excellent vibration damping in high-load and harsh environments.

The silicone oil anti-vibration ball uses damping fluid, air pressure, and springs to absorb and dissipate shocks, isolating both low and high-frequency vibrations. This enhances drone stability and improves the performance of systems like aerial gimbals, motors, sensors, and controllers, ensuring smoother operation and greater reliability.

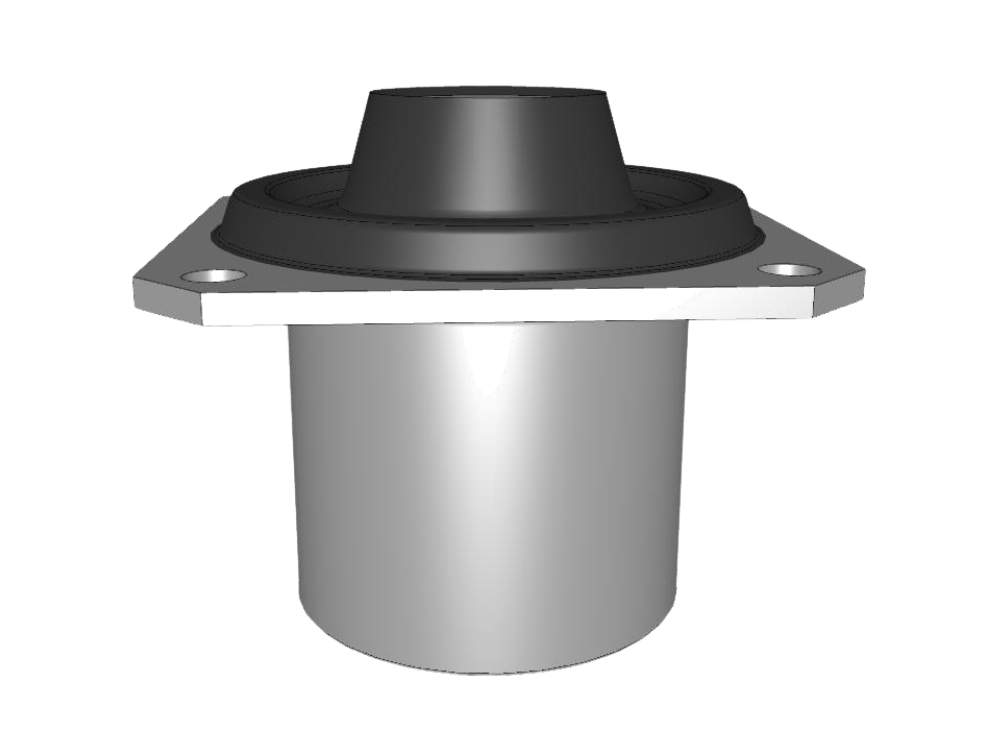

The conical hydraulic damper features an integrated spring and hydraulic design for precise vibration isolation and motion control. It ensures dynamic fluid response, energy dissipation, and high shock stability, making it ideal for engine and cabin mounting in construction, agricultural, and municipal vehicles.

Raw Materials

Production process

Testing Center

After-Sales Service

We offer a 3-year warranty for standard products and a 2-year warranty for those requiring high-temperature, acid/alkali, and oil resistance. In the event of any quality issues, we commit to providing a solution within 24 hours. Should the issue be confirmed, our factory will replace the product free of charge.