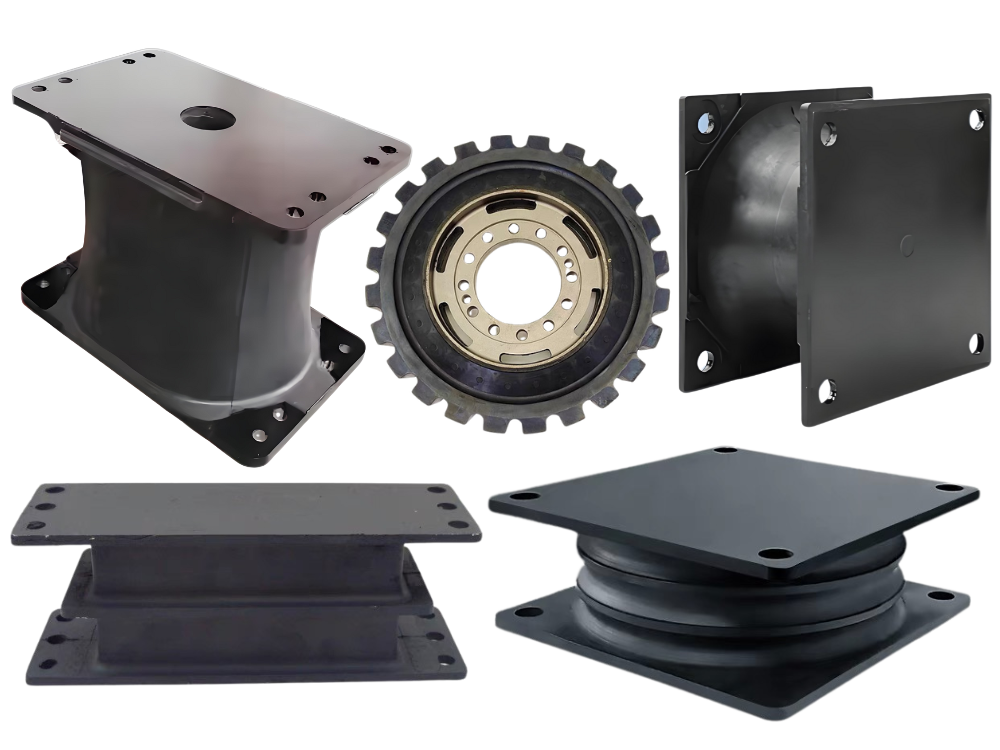

HEAVY DUTY RUBBER BUFFER

Heavy Duty Rubber Buffer series is designed to withstand high pulling forces in heavy-load applications. Made from ultra-high-strength rubber with a flexible molecular structure, it offers excellent shock absorption under high-frequency vibrations. These buffers feature outstanding resistance to repeated impact and fatigue, as well as superior wear resistance, effectively protecting machinery. Ideal for isolating harmful mechanical vibrations, they are widely used in industrial, mining, and material handling equipment.

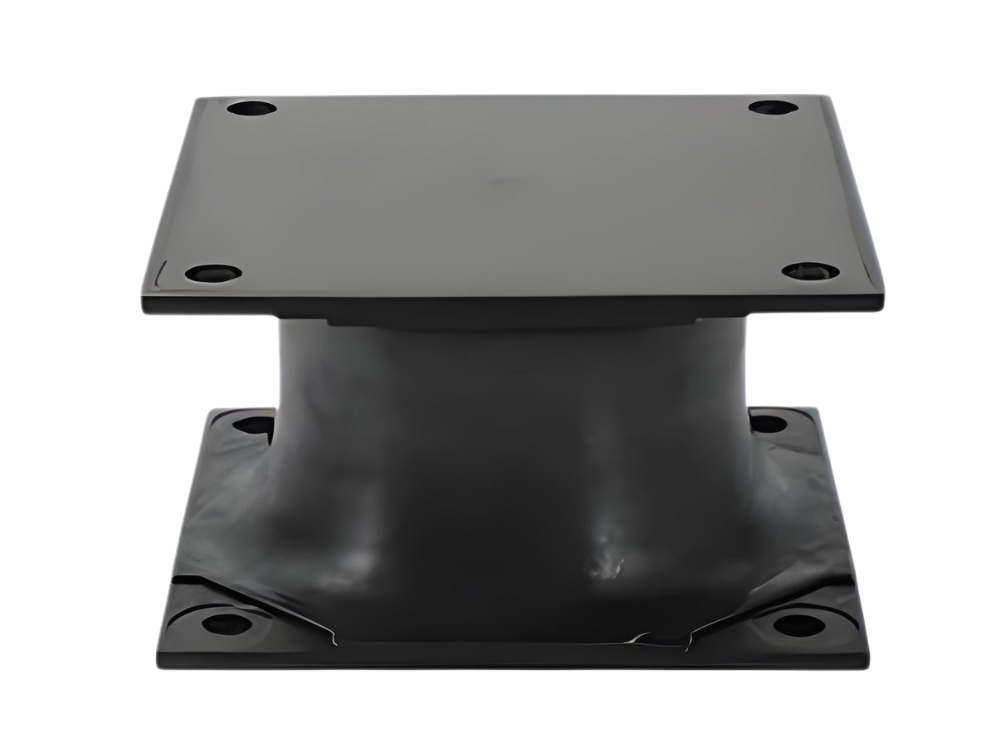

SW Type rubber buffer are ideal for heavy-duty equipment, effectively absorbing shock, noise, and high-frequency vibration. Their special rubber and hourglass design improve heat resistance, durability, and shear performance.

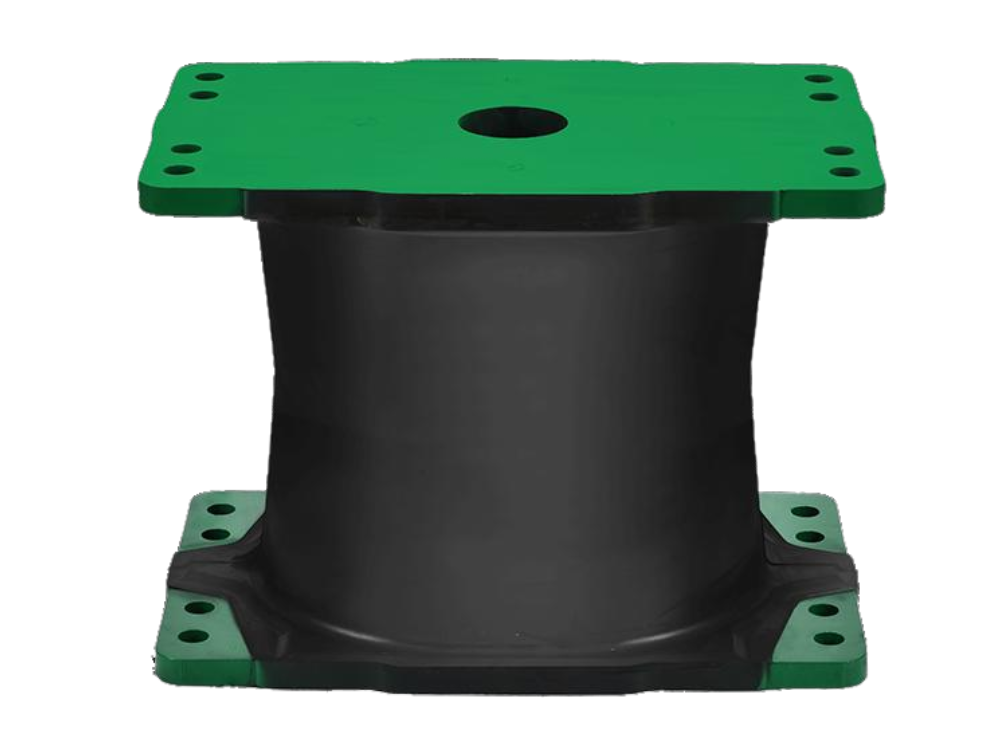

LZQ Type Coupling Components from durable rubber, they enhance machinery lifespan and reduce vibration. Ideal for industrial, construction, mining, marine, and transport applications, with customizable options available to meet specific needs.

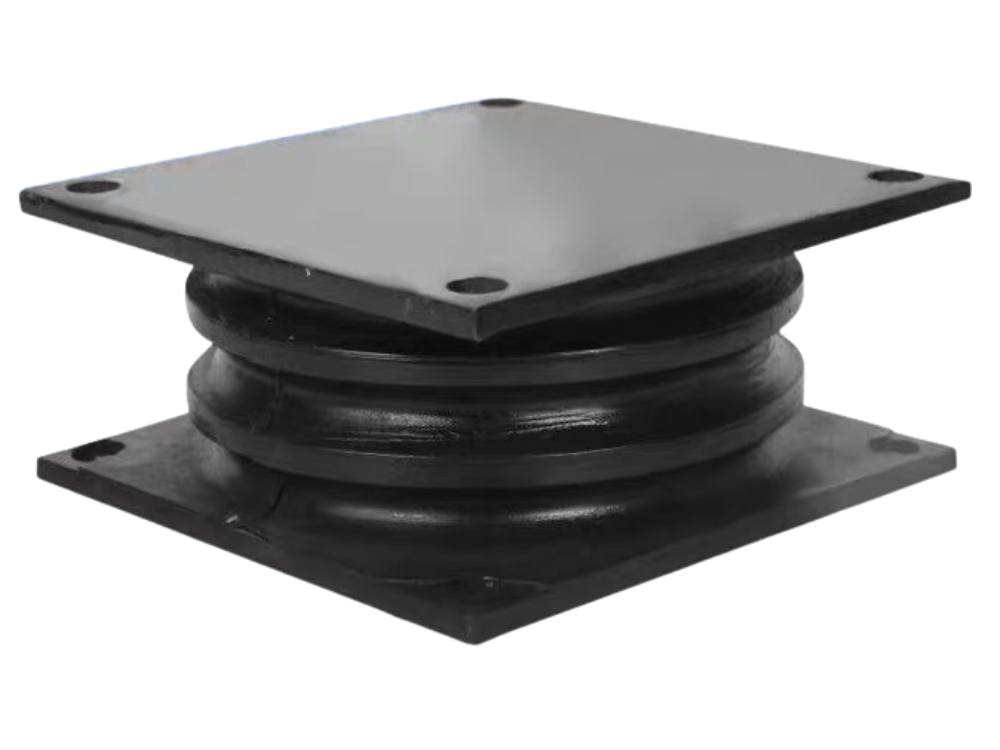

Large Piling Elastomers extend pile hammer life by absorbing shock and reducing wear between parts. Ideal for long piling jobs or extraction, they handle high shear deflection, ensure optimal transmission clearances, and minimize temperature fluctuations.

SWA mounts are built for heavy-duty applications in mining, quarrying, and construction. Featuring a high-dynamic rubber compound and layered steel plates, they withstand strong compression while minimizing deformation. The multi-layer design reduces deflection under load and ensures effective vibration isolation.

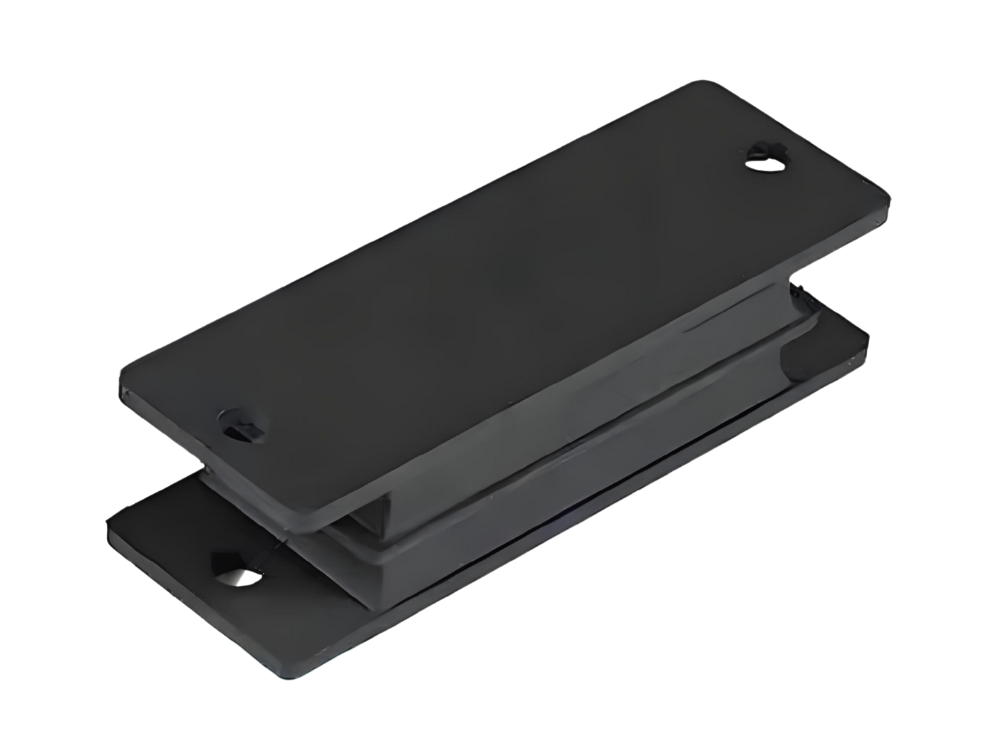

TEE Multi-Layer Antivibration Dampers feature rubber between metal plates, offering varying stiffness in multiple directions. Commonly used in engine mounts, conveyors, and vibratory equipment, they are ideal for printing presses, road rollers, feeders, crushers, and industrial machinery to effectively reduce shock and vibration.

In vibration and shock isolation, standard products may not meet complex conditions. We offer free, tailored solutions designed to suit your specific environment, load requirements, and equipment. Our expert team provides comprehensive support, from rubber formulation and structural design to precise dimension matching, ensuring optimal and stable system performance.

What are the structural and performance advantages of sandwich mounts?

Sandwich vibration isolators use high-strength bonding techniques to firmly integrate specially formulated elastomer materials with metal components. This ensures outstanding load-bearing capacity and long-lasting durability. The integrally molded design is compact and simple, minimizing fatigue and failure risks associated with multi-component assemblies. Its lightweight construction reduces the load on the equipment and allows for easy installation with minimal maintenance.

Performance Advantages:

High Load Capacity: Supports large static and dynamic loads, ensuring safe and stable operation of equipment.

Superior Vibration Absorption: Effectively isolates shocks and vibrations generated by machinery, reducing noise and wear.

Long Service Life and Reliability: Made with high-quality elastomers that resist wear and aging, suitable for a wide range of operating environments.

Easy Installation: Available in various sizes with metric and UNC thread options to fit different equipment types.

Low Maintenance: The compact, integrated design reduces the need for frequent servicing, lowering operational costs.

Sandwich vibration isolators are widely used in various equipment and machinery, including but not limited to: office devices (printers, copiers), motorcycles and light vehicles, HVAC systems, small motors and appliances, transport containers, feeder machines, and construction equipment such as compactors and vibratory rollers. Their diverse sizes and specifications meet different isolation needs and application requirements.

What is the working principle of a shear-type vibration isolator, and where is it commonly used?

Shear-type vibration isolators are ideal for heavy-duty machinery and high-vibration equipment due to their excellent energy absorption in shear and compression modes. These machines generate strong impacts and low-frequency vibrations during operation, which, if not properly isolated, can lead to fatigue, component failure, or safety issues. Shear isolators use elastic rubber layers to absorb and disperse these forces, stabilizing equipment and extending its lifespan.

Typical Applications:

Hydraulic Vibratory Compactors: Frequently used in foundation and road work; shear isolators reduce vibration transmission to handles and chassis, improving operator comfort and equipment durability.

Excavator Hammers: Absorb intense shock during hammering, protecting the mechanical structure and hydraulic system.

Mining Crushers: Handle massive vibrations during ore crushing. Special hourglass-shaped designs in shear isolators help relieve internal stress, ensuring long-term vibration damping and preventing premature aging.

Generator Sets: Isolate mechanical and engine vibrations, reducing noise and fatigue to enhance generator reliability.

Typically composed of two metal mounting plates and an intermediate elastic rubber body, shear isolators use high-performance elastomers known for heat resistance, wear resistance, and anti-aging properties. Their hourglass or special shapes help reduce stress concentration during shearing, improving durability and vibration isolation.

What are the common design forms and types of sandwich vibration isolators?

Sandwich vibration isolators come in various designs based on installation requirements and vibration control goals. Common forms include:

Cylindrical Sandwich Mounts (Bobbin Mounts):

Feature a cylindrical rubber core with metal plates and threaded studs on both ends. Suitable for general-purpose applications, offering stable support and a simple structure.Large Shear Mounts:

Consist of square metal plates clamping an elastomer core, usually without pre-set studs, allowing flexible installation on heavy equipment requiring high shear force absorption.Square Pad Mounts:

Use square rubber blocks combined with metal plates, ideal for large vibration areas or limited space applications.Custom Sandwich Isolators:

Employ patented bonding and elastomer design for enhanced durability and flexible mounting, suited for precision equipment and demanding applications.

Choosing the right design depends on vibration type (shear, compression, impact), load, installation space, and ease of maintenance to ensure optimal vibration damping performance.

What materials are used in sandwich vibration isolators? What are the pros and cons of different rubber types?

The materials used are critical to isolator performance and generally consist of metal components and elastomer polymers.

Metal Components:

Typically made from high-strength steel, stainless steel, or aluminum alloys for studs and mounting plates. These materials provide structural strength and load-bearing capacity, ensuring stable operation under industrial conditions.

Rubber Polymers:

Rubber is the core material for absorbing vibration and shock. Common types include:

Natural Rubber: Offers excellent elasticity and fatigue resistance but has limited tolerance to high temperatures and oils.

Silicone Rubber: Excellent resistance to heat and aging, suitable for high-temperature or complex conditions; however, it may have lower tear strength.

Neoprene (Chloroprene Rubber): Good wear and corrosion resistance, suitable for moderately harsh environments, though it is not fully oil-resistant.

The material selection directly affects service life, load-bearing capacity, and damping performance. Users should choose rubber and metal materials based on their specific conditions—such as temperature, load, and chemical exposure—for optimal performance and cost-efficiency.

What is the core function of a sandwich vibration isolator, and how does it protect equipment from vibration damage?

The primary function of a sandwich vibration isolator is to reduce the vibrations and shocks generated during equipment operation, ensuring safe and stable performance. It achieves this through:

Vibration Absorption and Isolation: The rubber sandwich layer absorbs and attenuates vibration energy, preventing it from transferring to the equipment structure and surrounding environment—reducing fatigue and damage.

Shock Buffering: In sudden impacts, the isolator disperses shock loads, avoiding breakage or deformation of parts.

Noise Reduction: By minimizing transmitted vibrations, it helps reduce equipment noise, creating a safer and more comfortable workspace.

Extended Equipment Life and Performance: Effective vibration control reduces wear and loosening of components, minimizing breakdowns and increasing longevity.

These isolators are widely used across HVAC systems, office automation, transportation, machinery, and construction equipment, playing a crucial role in maintaining equipment integrity and performance.

How to choose the right sandwich vibration isolator? Professional selection advice and contact information

The performance and longevity of sandwich vibration isolators depend heavily on appropriate material and structural choices. Each application has unique requirements, including load capacity, vibration frequency, ambient temperature, and more. To ensure the isolator performs optimally, careful selection tailored to the real-world operating environment is essential.

Our expert team has extensive experience and can recommend the most suitable materials and models based on your equipment type and application environment. For technical support or selection assistance, feel free to call our service hotline at +8613032112360 (WhatsApp) or contact us online. We provide one-on-one professional support for your vibration control needs.

Raw Materials

Production process

Testing Center

After-Sales Service

We offer a 3-year warranty for standard products and a 2-year warranty for those requiring high-temperature, acid/alkali, and oil resistance. In the event of any quality issues, we commit to providing a solution within 24 hours. Should the issue be confirmed, our factory will replace the product free of charge.