ENGINEERING

Rubber expansion joints have a wide range of applications and play an important role in various engineering industries. They are primarily used to connect pipeline systems, providing flexible interfaces that effectively accommodate stresses caused by displacements, vibrations, and thermal expansion and contraction during equipment operation. In practical applications, rubber expansion joints are widely used in construction, chemical engineering, water treatment, water supply and drainage, and HVAC systems. When using them, several important considerations should be noted: First, select the appropriate model and specifications, ensuring that the material of the joint is compatible with the conveyed medium to prevent chemical corrosion and high-temperature damage. Second, during installation, ensure the joint’s sealing performance by using the correct connection methods, such as flange or threaded connections, and follow the manufacturer’s installation instructions. Finally, regularly inspect and maintain rubber expansion joints to ensure their performance and safety, and promptly replace any joints that show signs of aging or damage to ensure the normal operation of the overall system.

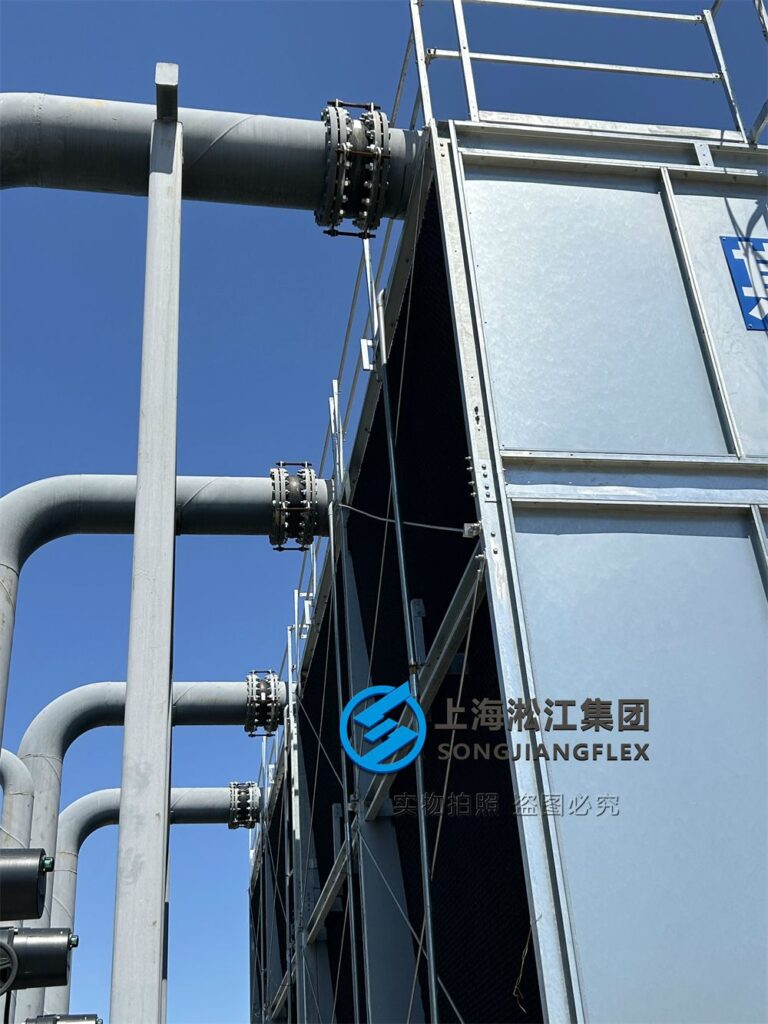

In the engineering industry, Songjiang rubber expansion joints and vibration isolators can provide high-quality solutions, as follows:

Rubber Expansion Joints Solution

Rubber expansion joints have a wide range of applications in the engineering industry, mainly used for connecting and sealing pipeline systems to address displacement and stress caused by factors such as temperature changes, pressure fluctuations, and equipment vibrations. Below are the main applications of rubber expansion joints in the engineering industry:

-

Pipeline Systems: Rubber expansion joints are widely used in pipeline systems in industries such as water supply, drainage, HVAC, petrochemicals, power, and metallurgy. They absorb displacement caused by temperature changes, ground settlement, equipment vibrations, etc., reduce stress concentration in pipelines, and prevent pipeline rupture or leakage.

-

Mechanical Equipment Connections: When connecting mechanical equipment to pipelines or other components, rubber expansion joints effectively cushion and absorb mechanical vibrations, reducing vibration transmission to the pipeline system and ensuring equipment stability and operational precision.

-

Pumps and Compressors: Rubber expansion joints are used at the inlet and outlet of pumps and compressors to reduce vibrations generated during pump or compressor startup, stopping, and operation. This prevents vibration transmission to the pipeline system and minimizes damage to the equipment.

-

Hot and Cold Water Pipelines: Rubber expansion joints can adapt to temperature changes in hot and cold water pipelines, preventing pipe deformation and leakage caused by thermal expansion and contraction, ensuring the normal operation of the pipeline system.

-

Power Plants and Petrochemical Industry: In power plants and petrochemical industries, rubber expansion joints are used for pipeline connections in high-temperature and high-pressure environments. They can withstand high-temperature steam, corrosion from chemicals, and thermal expansion and contraction caused by equipment operation, ensuring system sealing and safety.

-

Vibration Isolation: Rubber expansion joints can also serve as vibration isolators, especially in applications where vibration isolation is required, such as in HVAC systems, pump stations, and other equipment. They reduce vibration transmission and lower noise levels.

Vibration Isolators Solution

In the engineering industry, vibration isolators are widely used to reduce and isolate vibrations and noise in mechanical equipment and structures, improving equipment performance and extending its service life. Below are some common applications of vibration isolators in the engineering industry:

Mechanical Equipment: Vibration isolators are used in various rotating and reciprocating machinery (such as engines, pumps, fans, and compressors) to reduce vibrations generated during operation. They prevent vibration from being transmitted to the surrounding environment, thus reducing noise and equipment wear.

Building Structures: Vibration isolators are installed in high-rise buildings, bridges, and other structures to absorb vibrations caused by external impacts like wind and earthquakes, protecting the stability of the structure and enhancing safety.

Industrial Equipment: In industrial equipment that requires high precision, such as machine tools, CNC machines, and presses, vibration isolators help reduce the impact of minor vibrations during operation, ensuring production accuracy.

Transportation and Aerospace: In rail transport, aerospace, and marine vessels, vibration isolators help counteract vibrations and shocks caused by movement and external conditions, protecting equipment components and enhancing safety and comfort.

Electronic Equipment: Vibration isolators can be installed in precision electronic equipment (such as instruments and communication devices) to prevent external vibrations from affecting the performance of the equipment or the stability of data transmission.

Other Projects Involved by Songjiang - Reference List

The Dalian Haiyi Changzhou Phase I Thermal Engineering Project uses high-temperature rubber joints supplied by our factory, which effectively reduce vibration and noise.

The Chongqing Jiangbei International Airport Project in Yubei District uses spring shock absorbers for central air conditioning units supplied by our company, achieving noise reduction and vibration damping.

The Changchun Ice Training Base Project employs low-temperature rubber expansion joints. All raw materials undergo testing in our factory’s laboratory before mass production to ensure product stability.

The De Long Farm Project of the 124th Regiment in Urumqi uses large-diameter DN450 rubber expansion joints. Our factory adds anti-pull limit devices for rubber joints over DN200.

The National Library Project uses rubber expansion joints produced by our factory. We also provide high-quality rubber expansion joints for other projects at the China National Library, with a five-year warranty.

The Wuhan Metro Line 6 Cooling Station Project uses damping spring shock absorbers made by our company. Each unit is tested to meet factory requirements before shipment.

The China Railway Engineering Machinery Research Institute Project employs oil-resistant rubber joints supplied by us, primarily for shock absorption and noise reduction.

Our company supplies rubber joints for major outlet projects nationwide, including the rubber joints used in the Nanjing Xianlin Golden Eagle Outlet Phase II Project.

The Xi’an Chaoyang International Plaza Project uses high-pressure rubber expansion joints produced by our factory, specifically 25kg DN300/DN400 rubber soft joints.

We provide spring shock absorbers for air conditioning units for various urban complex projects, such as the spring shock absorbers used in the Jiangyin Chengxing Complex Project, which are produced by our factory.