MINING AND MINERALS PROCESSING

Rubber expansion joints are widely used in mining and minerals processing for applications such as slurry transport, water treatment, air conveyance, and equipment connections. They effectively absorb vibrations and displacements, ensuring the stability and sealing of pipelines. When using them, it is important to select appropriate wear-resistant and corrosion-resistant materials, ensure proper installation to prevent leaks, regularly inspect and maintain the joints, and adhere to industry standards to enhance system safety and reliability.

In the mining and minerals processing industry, Songjiang rubber expansion joints and vibration isolators can provide high-quality solutions, as follows:

Rubber Expansion Joints Solution

In the mining and minerals processing industry, rubber expansion joints play a crucial role in ensuring smooth and efficient operations. These flexible components are designed to absorb vibrations, thermal expansions, and misalignments that occur in piping systems, which are common in mining operations and processing plants.

Key Benefits of Rubber Expansion Joints in Mining and Minerals Processing:

-

Vibration Isolation

Mining and mineral processing equipment, such as crushers, mills, and conveyors, generate substantial vibrations. Rubber expansion joints are effective in isolating these vibrations from the piping systems, preventing damage to equipment and reducing wear and tear. -

Thermal Expansion Compensation

Equipment and pipelines in mining facilities often experience temperature fluctuations due to heat generated by machinery or external factors. Rubber expansion joints accommodate these thermal expansions and contractions, preventing stress buildup in the piping system and reducing the risk of leaks or cracks. -

Misalignment Absorption

Mining and processing equipment can be subject to misalignment due to movement, shifting, or settling. Rubber expansion joints provide flexibility to absorb this misalignment, ensuring that the piping systems remain intact and operational without causing undue stress on the joints or equipment. -

Corrosion Resistance

In mining and minerals processing plants, pipelines often come into contact with harsh chemicals, abrasive materials, and corrosive environments. Rubber expansion joints are resistant to many chemicals and can withstand the aggressive conditions commonly found in these industries, helping to extend the lifespan of the system. -

Improved Safety and Reliability

By preventing pipeline failure, reducing vibrations, and ensuring proper alignment, rubber expansion joints enhance the overall safety and reliability of mining and minerals processing operations. This leads to fewer unplanned shutdowns and reduces the risk of accidents caused by equipment malfunction. -

Easy Installation and Maintenance

Rubber expansion joints are easy to install and maintain, which helps to minimize downtime in mining and processing plants. They can be custom-made to meet specific requirements of the operation, ensuring that they integrate seamlessly into existing systems.

Applications in Mining and Minerals Processing:

- Conveying Systems: Rubber expansion joints are used in conveyor systems to absorb vibration and thermal expansion, ensuring smooth transport of materials.

- Piping for Slurry Transport: The mining industry often uses slurry pipelines, which carry a mixture of water and minerals. Rubber expansion joints help prevent damage caused by the rough materials and variations in temperature.

- Dust Collection Systems: Rubber expansion joints are used in the ducts and pipes of dust collection systems to reduce vibration and prevent leaks.

- Crushing and Milling Equipment: These systems generate high levels of vibration and heat. Rubber expansion joints mitigate the impacts of these factors on the piping network.

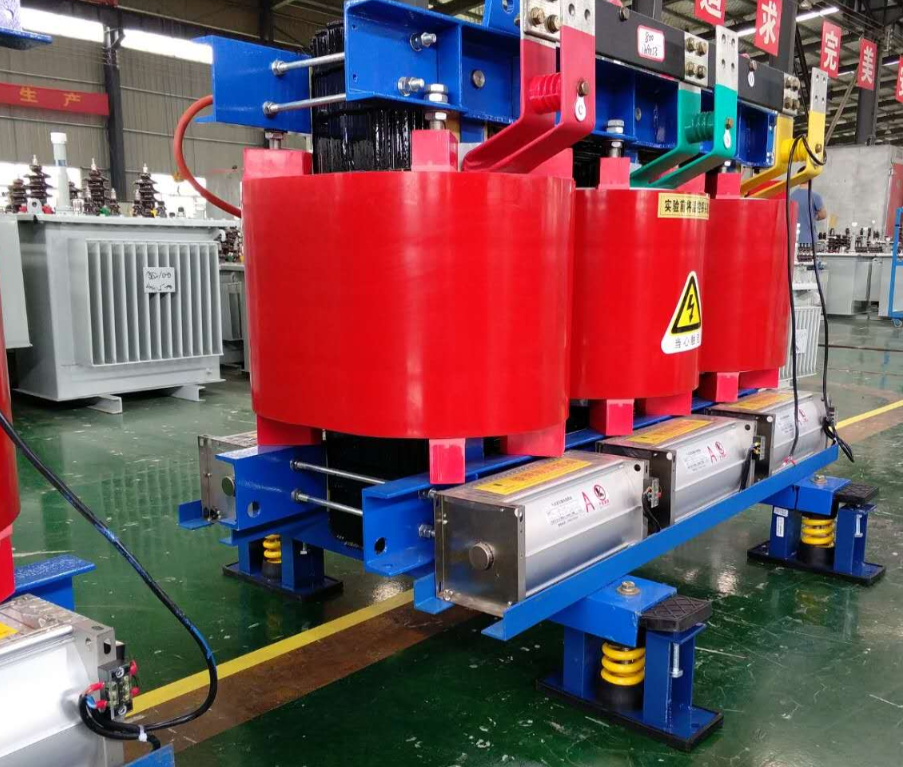

Vibration Isolators Solution

Common Applications in Mining and Minerals Processing:

- Crushers and Mills: Vibration isolators reduce vibrations caused by crushing and grinding, protecting both the machines and nearby structures.

- Conveyors: These isolators help maintain the stability of conveyor systems, reducing vibrations that can affect material transport and handling.

- Pumps and Compressors: Used to isolate vibrations in pumps and compressors, which are essential in fluid and slurry handling systems.

- Dust Collection and Ventilation Systems: Vibration isolators are used in ducts and fans to prevent noise and wear due to high vibrations in ventilation and dust control systems.

Conclusion:

Vibration isolators are critical components in mining and minerals processing operations. By effectively managing the vibrations produced by heavy machinery, they enhance equipment longevity, improve worker safety, and ensure stable and efficient plant operations. These isolators contribute to smoother workflows and greater cost efficiency, making them indispensable for modern mining environments.

BASF China is upgrading its production system with metal hoses, rubber expasion joints, and rubber /spring vibration isolators for a comprehensive overhaul.

Spring isolators for the Lubrizol specialty chemicals project in Shanghai, aimed at upgrading and retrofitting vibration control in the factory's chemical piping system.

Provide wear-resistant and oil-resistant rubber joints for the mud piping system of China Petroleum Corporation (CNPC) Chuanqing Drilling Engineering Company.

LG Chem's Guangzhou factory is undergoing a complete overhaul of its ducting system, utilizing corrosion-resistant isolators, which provide excellent vibration reduction.

Other Projects Involved by Songjiang - Reference List

- Our company provides high-quality spring shock absorbers for a number of titanium alloy series product R&D projects, including the rubber vibration strips used in the Hunan Jintian Titanium Industry Technology Project.

- The rubber expansion joints used in the Baogang 5 Million Tons Pellet Drum Flue Gas Fluorine Removal and Desulfurization Engineering Project are produced by our company.

- The sintering flue gas desulfurization rubber joints used in the Baogang Rare Earth Steel Smelting Sintering Plant Flue Gas Desulfurization Project are manufactured by our factory, with a 3-year product warranty.

- For the Guangxi Laibin Huaxi Zinc Smelting Plant Project, our company supplied the PTFE expansion joints for their smelting purification system, using imported PTFE materials from Japan.

- Our company provides desulfurization rubber expansion joints for many steel enterprises, such as the products used in the Shanxi Gaoyi Phase II Gas Boiler Power Generation Desulfurization Project.

- The rubber expansion joints with American standard flanges supplied by our company are used in the China Steel Australia Rocklands Copper Mine Project, where they play a role in vibration reduction and noise reduction.

- The rubber joints used in the steelmaking workshop of Shandong Laiwu Taishan Steel are supplied by our company. These steelmaking rubber joints feature high elasticity, high air tightness, resistance to media, and weather resistance.

- The flexible waterproof casings with a diameter of DN1200 supplied by our company are used in the Mongolia Oyutolgoi Gold Copper Mine Project.

- For the China Steel Australia Rocklands Copper Mine Project, we supplied radiation-resistant rubber joints designed to protect against ultraviolet radiation. Based on the client’s requirements, we developed a special rubber formula to meet the radiation resistance needs.