WATER & WASTEWATER TREATMENT

Rubber joints are widely used in water and wastewater treatment for applications such as pipeline connections, pump and valve connections, wastewater treatment equipment, and inlet and outlet systems. They effectively absorb vibrations, reducing pipeline stress and extending equipment lifespan. Additionally, made from corrosion-resistant materials, rubber joints provide excellent sealing performance to prevent leaks and enhance system safety. Their simple design allows for easy installation and maintenance, while they adapt to temperature changes and pipeline displacements, ensuring system flexibility and reliability.

In the water and wastewater treatment industry, Songjiang rubber expansion joints and vibration isolators can provide high-quality solutions, as follows:

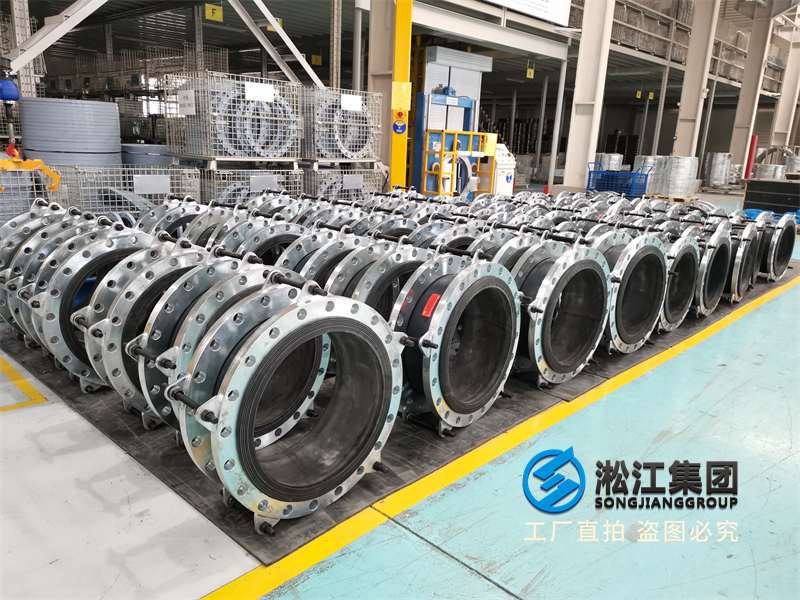

Rubber Expansion Joints Solution

In the water and wastewater treatment industry, rubber expansion joints play a crucial role in protecting pipeline systems, managing pressure changes, and reducing wear and tear in equipment. They are flexible, durable components designed to absorb movement, reduce noise, and isolate vibrations, making them ideal for water processing facilities that deal with a wide range of flows, chemicals, and environmental conditions.

Key Benefits of Rubber Expansion Joints in Water and Wastewater Treatment

Absorbing Pipe Movements and Misalignments

Water and wastewater systems are subject to thermal expansion, pressure fluctuations, and equipment vibrations. Rubber expansion joints can absorb axial, lateral, and angular movements, helping to prevent damage to pipes, pumps, and other components by relieving stress on the system.Corrosion and Chemical Resistance

The materials used in rubber expansion joints are resistant to corrosion, making them suitable for facilities handling various chemicals and aggressive wastewater contents. This resistance prolongs the service life of the joints and protects the overall system from chemical wear.Vibration and Noise Reduction

Pumps, compressors, and other machinery in treatment plants can cause vibrations that, if unchecked, can damage equipment and cause noise issues. Rubber expansion joints isolate vibrations, enhancing plant safety and reducing noise levels for a more comfortable working environment.Pressure Change Compensation

Water and wastewater systems experience frequent pressure fluctuations due to pump operation cycles. Rubber expansion joints are designed to withstand these fluctuations, preventing water hammer effects and pressure surges that can damage pipeline systems.Ease of Installation and Maintenance

Rubber expansion joints are lightweight and easy to install, simplifying the process for facilities with extensive piping networks. Additionally, they require minimal maintenance, making them a cost-effective choice for water treatment plants focused on efficiency and longevity.

Vibration Isolators Solution

In Shanghai wastewater treatment plants, vibration isolators are applied to mitigate the impact of vibrations caused by pumps, compressors, and other mechanical equipment. These isolators effectively absorb and dampen vibrations, preventing them from transferring through the structure, which can lead to damage or wear on pipes, tanks, and other critical components. By reducing vibrations, the isolators help protect the equipment from excessive stress, minimize noise levels, and extend the life of the infrastructure.

Solutions Provided by Vibration Isolators:

Minimized Equipment Wear and Tear

Vibration isolators prevent the transmission of mechanical vibrations to critical systems, reducing strain on pipes, joints, and tanks, and preventing premature failure.Improved Operational Stability

By isolating equipment vibrations, these devices help maintain smoother operations, increasing the overall efficiency of the treatment process and minimizing the risk of operational interruptions.Noise Reduction

Vibration isolators contribute to creating a quieter environment by absorbing high levels of noise generated by machinery, leading to a more comfortable working environment for plant personnel.Extended Equipment Life

By reducing mechanical stress, vibration isolators help extend the lifespan of pumps, motors, and other equipment, minimizing the need for frequent repairs and replacements.Energy Efficiency

With less energy lost due to vibrations and reduced wear on machinery, vibration isolators contribute to the overall energy efficiency of the wastewater treatment process.

In summary, the application of vibration isolators in Shanghai’s wastewater treatment plants provides essential solutions to protect equipment, improve operational efficiency, reduce noise, and extend the longevity of plant infrastructure. This ultimately results in cost savings, better resource management, and enhanced reliability for the wastewater treatment process.

Veolia Wastewater Treatment Uses Reducer Rubber Expansion Joints Made with Mitsui 4045 EPDM Rubber

Suez Group’s Sino-French Water Investment and Chongqing Water Group Joint Venture in Partnership with Songjiang

The China Three Gorges Dam Project is outfitted with high-quality expansion joints provided by Songjiang.

KSB Water Treatment Systems Equipped with Songjiang Rubber Expansion Joints and Vibration Dampers

Other Projects Involved by Songjiang - Reference List

-

The Changzhi Urban Sewage Treatment Plant Expansion Project uses our factory-produced rubber expansion joints, primarily limiting rubber expansion joints, to ensure safe operation of the project with a 5-year quality guarantee.

-

The Taixing Sewage Treatment Plant Project utilizes our company’s rubber expansion joints, metal hoses, and expansion joints, which are stable and reliable in quality, offering exceptional performance.

-

In 2014, our company supplied acid- and alkali-resistant rubber joints for the Shouguang Seawater Desalination Project in Shandong, using Japan’s Mitsui 4045 ethylene propylene diene monomer (EPDM) material, with a 50% rubber content, no reclaimed rubber, ensuring high-quality raw materials.

-

The Wenling Taihu Reservoir Pump Pipeline Project employs our company’s hinge-type double-ball rubber expansion joints to absorb vertical fluctuations in the pipeline, thus protecting the normal operation of the pump pipeline.

-

We supply hot-dip galvanized flange rubber joints for many municipal sewage treatment projects, including the Suzhou Wuzhong District Municipal Sewage Treatment Project. The hot-dip galvanized flange surface is treated to be corrosion-resistant, ensuring a long service life.

-

The Dongguan Tangxia Water Supply Company’s Drinking Water Pipeline Renovation Project uses DN800 large-diameter rubber expansion joints, for which we provide environmentally friendly rubber expansion joint products to major water supply companies.

-

Our company provides high-quality rubber expansion joints for the Caofeidian Port Seawater Desalination Project, primarily using EPDM rubber with a 50% rubber content and no reclaimed rubber, ensuring guaranteed quality.

-

The Zhongshan Water Supply Dongfeng Branch Pump House Project employs DN1000 and DN800 large-diameter single-ball rubber joints, which can reduce vibration and noise, widely used in various piping systems.

-

We supply DN1200 rubber joints for many sewage treatment plant projects in Nanchang City, Jiangxi Province, including the DN1200 large-diameter rubber expansion joints used in the Nanchang Jiulong Lake Sewage Treatment Plant Project.

Our company provides high-quality steel spring dampers for numerous sewage treatment plant renovation projects, ensuring guaranteed quality, including the spring dampers used in the Shanghai Lingang Sewage Treatment Plant Phase II Renovation Project.