SDS Type Diaphragm Pneumatic Vibration Isolator

SDS Type Diaphragm Pneumatic Vibration Isolator is a high-performance vibration control solution designed for precision equipment and harsh environments. With ultra-low natural frequency and adaptive air damping, it ensures outstanding vibration isolation across a broad frequency range. Ideal for use in semiconductor, aerospace, optical, and medical industries.

What are the core parameters of the SDS Type Diaphragm Pneumatic Vibration Isolator?

The SDS diaphragm isolator offers precision-level performance through advanced technical parameters:

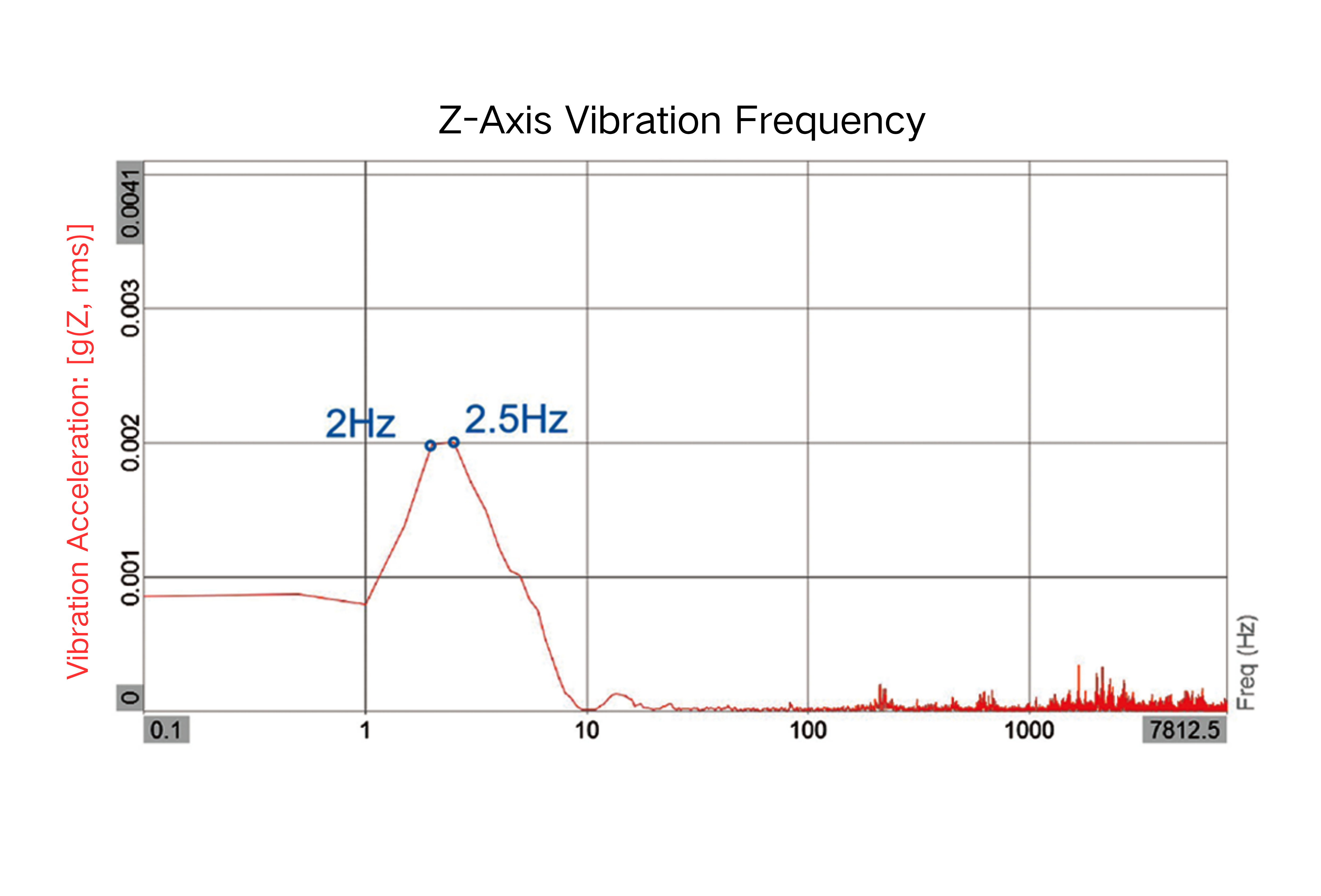

Vertical natural frequency: 2–3 Hz (depending on load)

Horizontal natural frequency: 2–3 Hz (based on foundation stiffness)

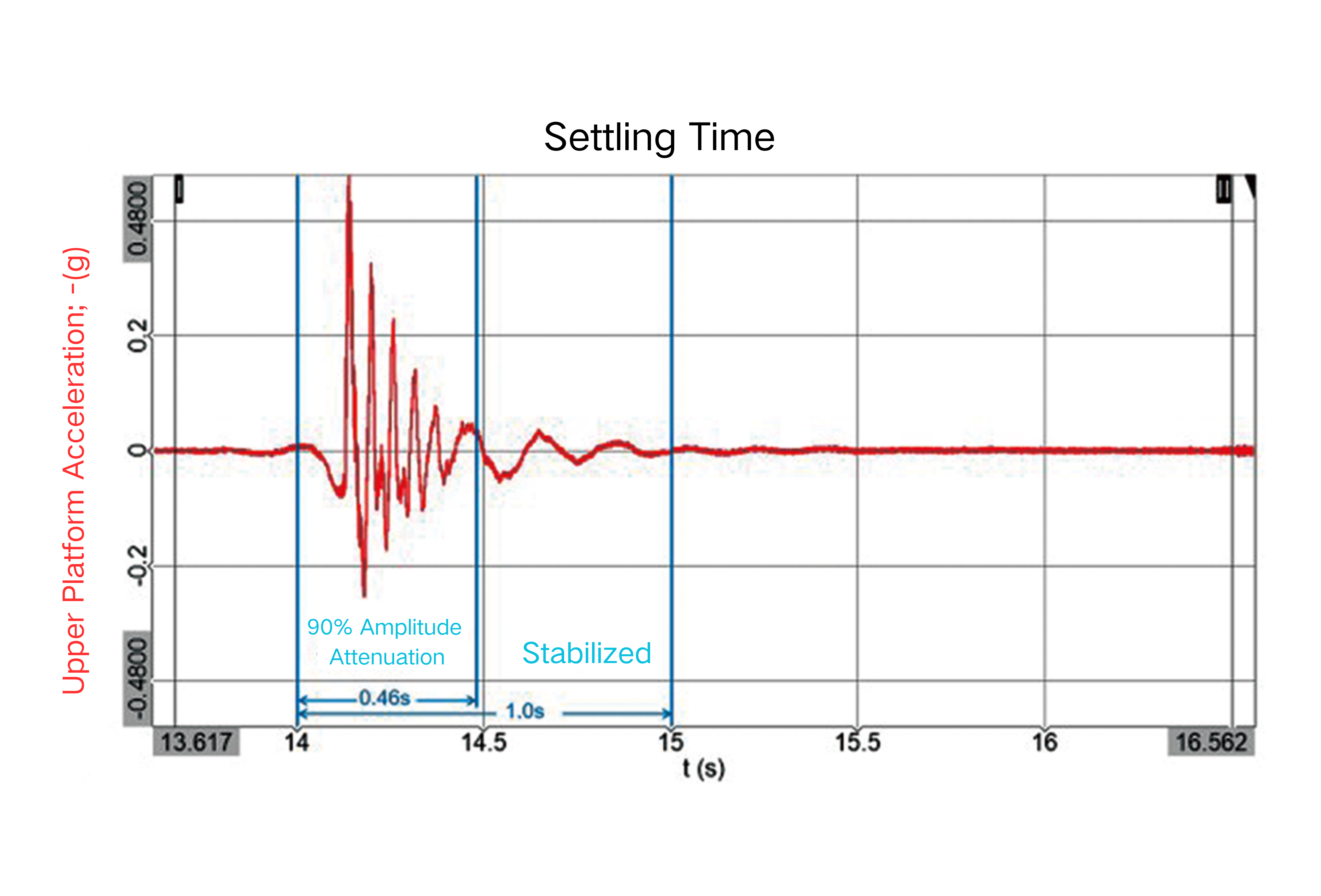

System stabilization time: <1.5 s for 90% vibration attenuation

Effective tuning time: <0.5 s

Repositioning accuracy: ±0.01 mm with high-precision Casby valve

Vibration control level: VC-C (ISO-ANSI compliant)

Operating temperature: -57°C to +60°C

Isolation performance:

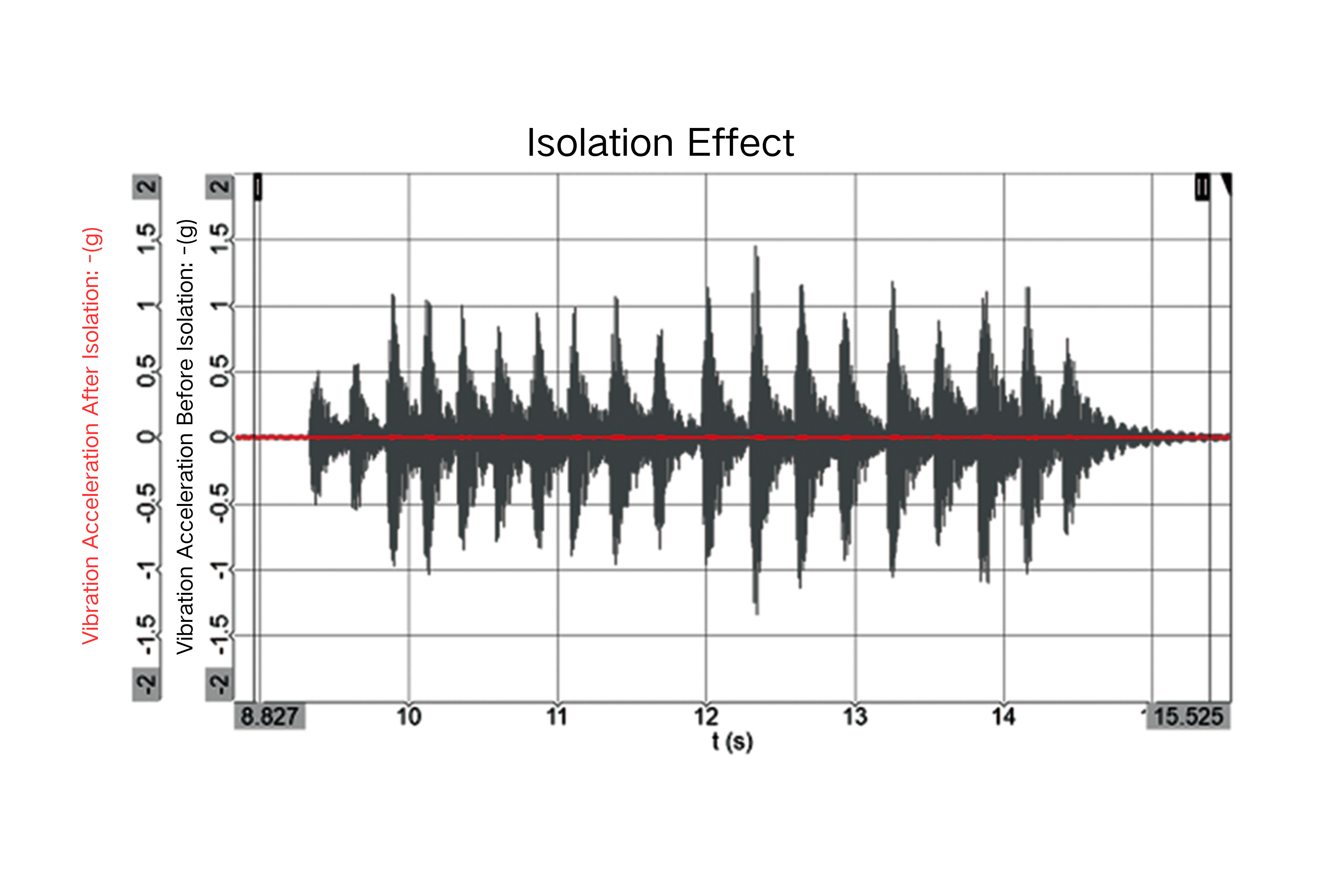

85% vibration attenuation across full frequency spectrum

90% at 50 Hz

99% at 100 Hz

Adjustable equivalent stiffness and damping, allowing system tuning for variable load conditions

These parameters make it suitable for the most demanding precision environments.

Where can the SDS Pneumatic Vibration Isolator be applied?

This vibration isolator is engineered for environments where absolute vibration control is essential:

Precision metrology equipment (e.g., laser interferometers)

Optical inspection systems (e.g., lithography machines)

Medical imaging devices (e.g., MRI systems)

Nano-level processing platforms

High-precision machine tools

Aerospace and military-grade systems

Thanks to its adaptive performance and high-level stability, SDS pneumatic isolators are trusted in both research labs and critical production lines around the world.

What are the key functional features of the SDS diaphragm isolator?

The SDS diaphragm vibration isolator combines intelligent control with mechanical precision to deliver:

1. Automatic Leveling System

High repeatability with ±0.01 mm positioning accuracy

Dual-mode adjustment:

Inflation mode for overload compensation

Pressure relief mode for underload tuning

2. Adaptive Vibration Isolation

Automatic pressure matching (working range: 0.3–0.6 MPa)

Nonlinear stiffness compensation technology, ensuring optimal isolation performance even with load variation

This intelligent system design makes SDS isolators extremely efficient for isolating high-frequency and low-frequency vibrations simultaneously.

SDS Type Diaphragm Pneumatic Vibration Isolator

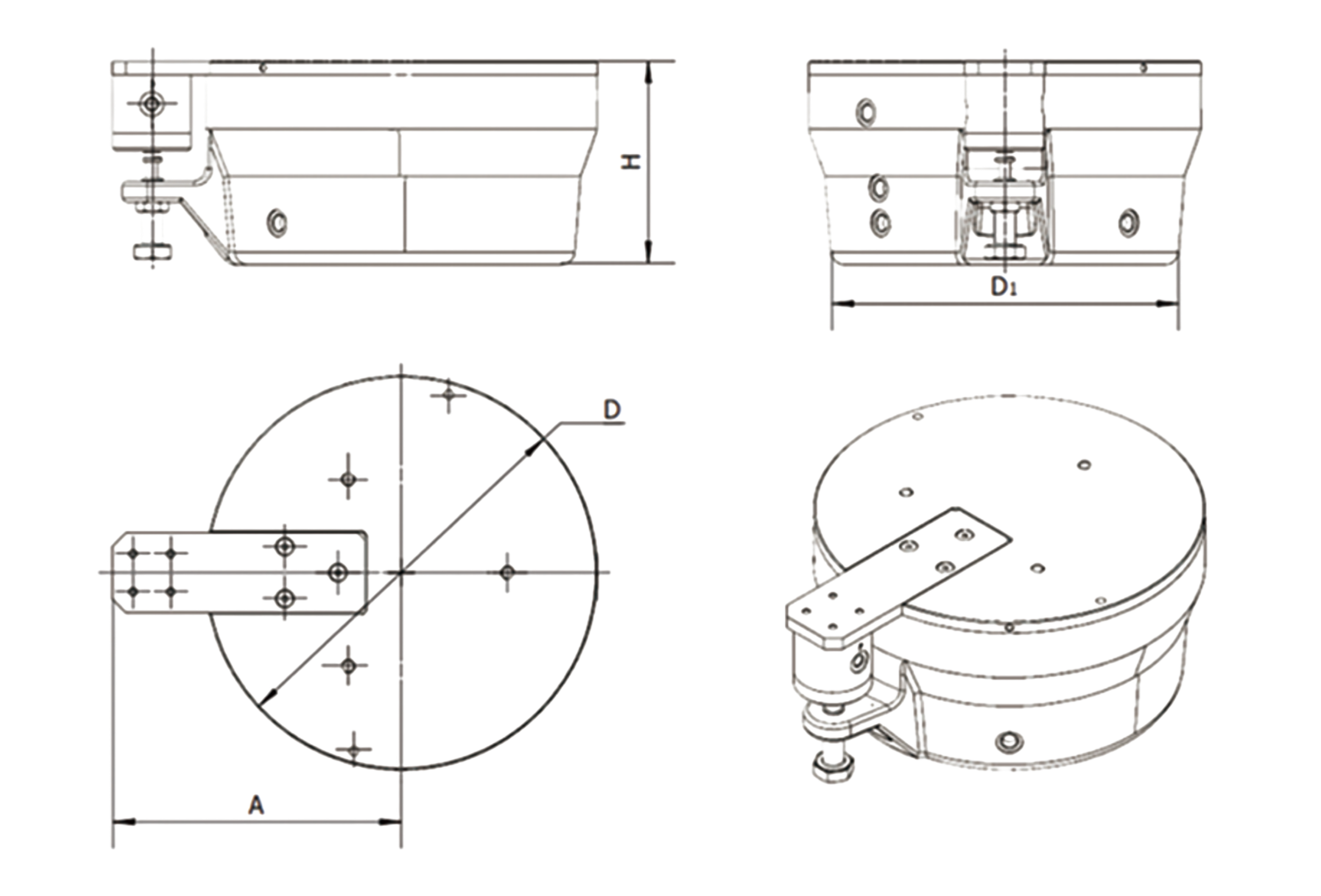

SDS Type Diaphragm Pneumatic Vibration Isolator Data Chart

| NO. | A (mm) | H (mm) | D (mm) | D1 (mm) | Height Range (mm) | Load (kg) |

|---|---|---|---|---|---|---|

| SDB001 | 165 | 146 | 190 | 150 | – | 400 |

| SDB002 | 170 | 146 | 200 | 150 | – | 950 |

| SDB003 | 190 | 153 | 260 | 220 | – | 2000 |

| SDB005 | 268 | 153 | 296 | 260 | – | 3500 |

| SDB006 | 310 | 153 | 380 | 350 | – | 6500 |

Measured curve graph

The gray curve represents the vibration acceler-ation before vibration isolation; the red curverepresents the vibration acceleration after vi-bration isolation.

Under rated load, the natural frequency of theequipment is below 3HZ. The natural frequencywill be affected by the weight of the load, andthe natural frequency of the system will increasewhen the load is insufficient.

When the system is affected by external distur-bances, the self-balancing time is within 1.5s.The amplitude decays by 90% in less than 0.5s.

We are a manufacturer specializing in the research and production of rubber air springs, with over 30 years of experience. Our products can serve as replacements for internationally renowned brands such as Firestone, Contitech, Dunlop (FR), Festo, Norgren, and Weforma.

Due to limited information available on our website, please email us at [email protected] for more detailed drawings and specifications of our air springs