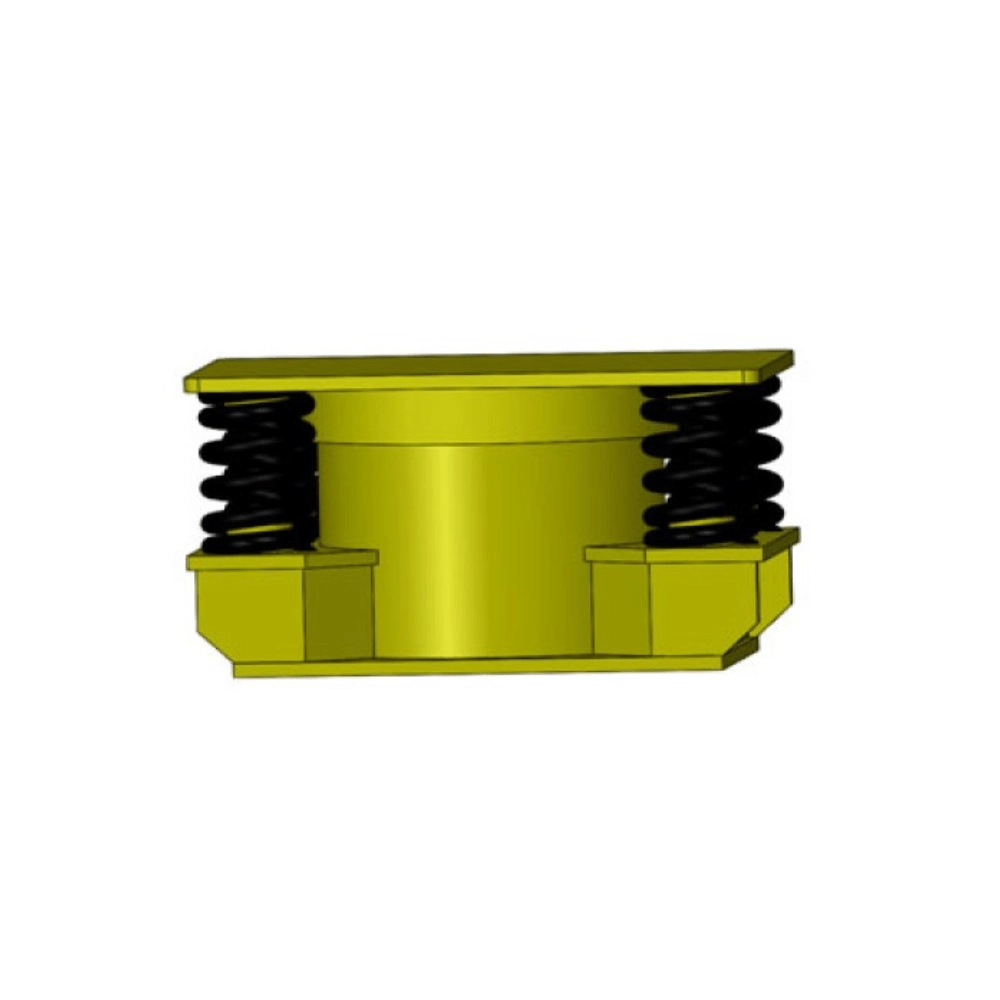

GRB-F type Damping Vibration Isolators for Crushers

GRB-F Type damping vibration isolators effectively reduce over 90% of vibrations, extend equipment lifespan (30+ years), and minimize maintenance. They include anti-seismic features for realignment, overload protection, and no-bolt installation with anti-slip pads. The isolators also offer load display for easy installation and monitoring, ensuring safe and efficient operation.

What are the advantages of using GRB-F Type damping vibration isolators in crushers and coal mills?

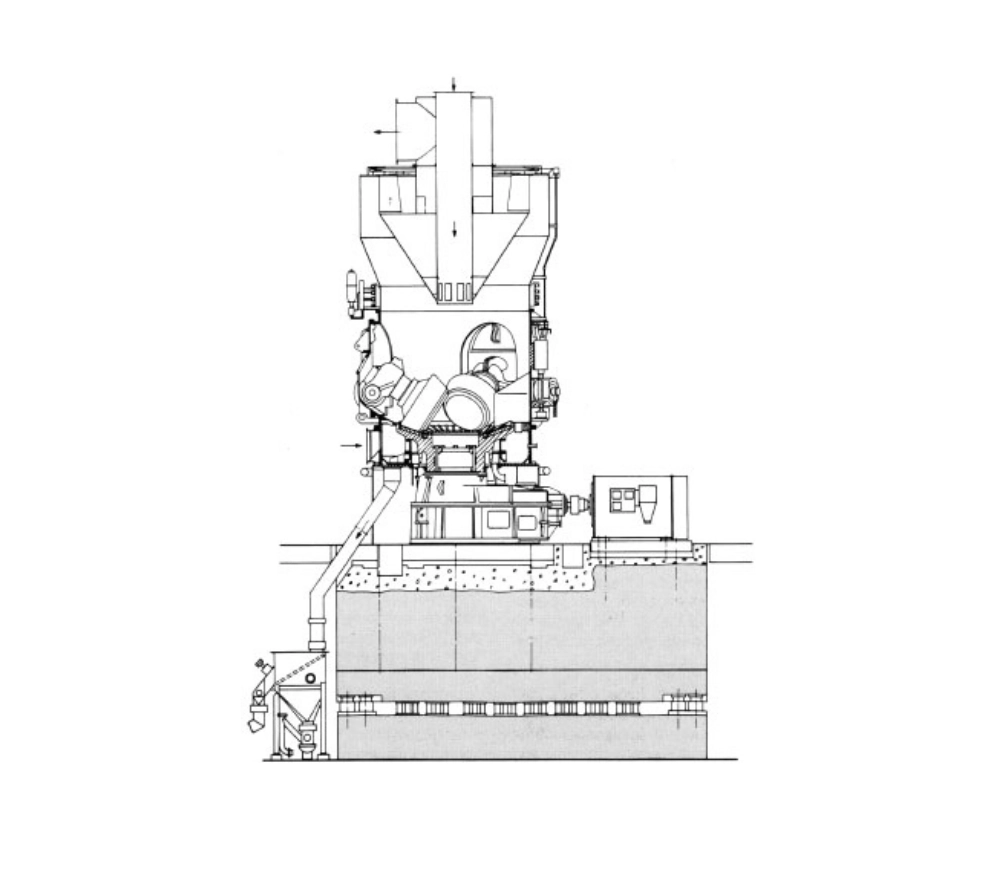

Crushers and coal mills produce significant vibrations due to their structural design, which can impact both the machinery and the surrounding environment. These vibrations may cause mechanical wear, decreased precision, and potential damage to the structure over time. To counteract this, additional foundation blocks or rigid platforms are often added to absorb and reduce the vibrations, thereby enhancing system stability and stiffness. This improves overall structural integrity, leading to smoother operation, extended equipment lifespan, and reduced maintenance costs, resulting in a more reliable and efficient production process.

Application of GRB-F Type Damping Vibration Isolators in Crushers and Coal Mills

GRB-F Type damping vibration isolators are specifically designed to reduce the intense vibrations produced by crushers and coal mills during operation. These machines generate strong dynamic forces that can compromise their structural integrity and affect the surrounding environment. The isolators absorb and dissipate these vibrations, minimizing their transmission and protecting nearby equipment and structures.

These isolators are ideal for crushing equipment, such as coal crushers in power plants. The design includes a metal housing, spiral steel springs, high-viscosity damping material, and anti-slip base plates.

- The metal housing is welded and coated with shot blasting and powder coating, ensuring corrosion and oxidation resistance, making it suitable for demanding environments with heavy loads, high impacts, humidity, and dust.

- The spiral steel springs are made from imported spring wire from Japan, ensuring high precision and longevity, thanks to shot blasting and powder coating treatments.

- The damping material is made from imported, non-toxic, non-polluting substances, offering excellent performance in both high and low temperatures. It is abrasion-resistant, aging-resistant, chemically stable, and has a linear viscosity for precise control over the damping coefficient.

What are the advantages of the GRB-F type damping spring isolator?

- The GRB-F Type damping vibration isolators effectively absorb dynamic loads, suppress resonance, and isolate over 90% of vibrations.

- With a lifespan exceeding 30 years and minimal maintenance, they offer long-term reliability.

- The isolators are equipped with anti-seismic functionality, allowing easy realignment and leveling during foundation settlement.

- They utilize anti-slip pads, eliminating the need for bolts.

- With overload protection, the isolators safeguard the equipment during emergencies, preventing damage and ensuring safe operation.

- A built-in load display allows for on-site monitoring, simplifying installation, leveling, and maintenance while ensuring consistent performance.