KDT Full-faced Expansion Joints

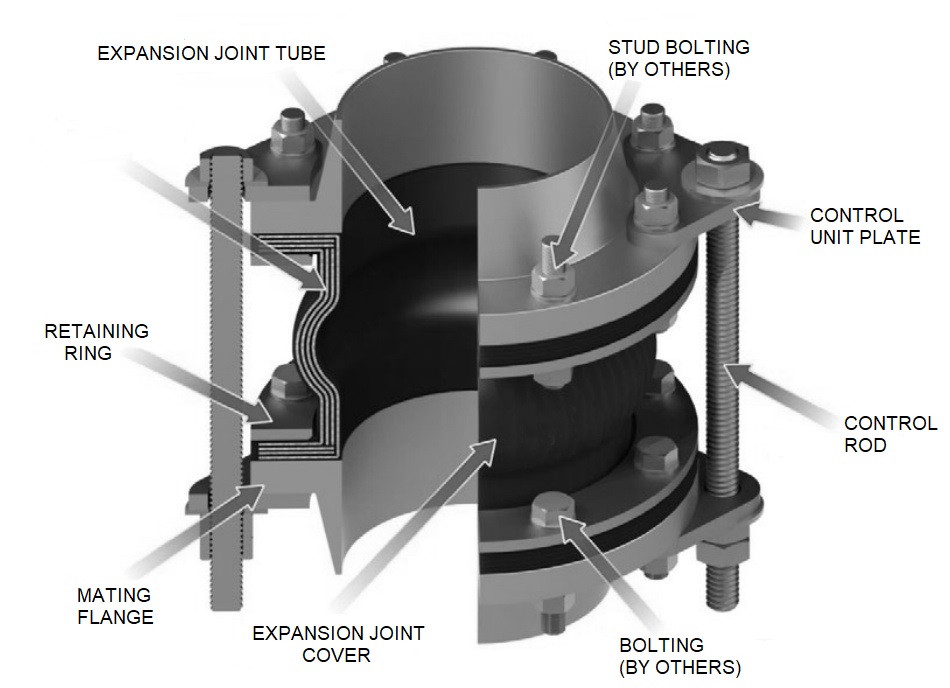

Single wide arch large flange molded rubber expansion joints are specifically designed to handle the most demanding piping system configurations. These joints utilize a single wide arch structure, which is particularly effective in reducing or eliminating common issues such as noise, vibration, misalignment, offset, and turbulence. This series of expansion joints is suitable for a diverse range of industrial applications and is available in both open arch and filled arch designs

What is the KDT Full-faced Expansion Joints?

Key Features of Single Wide Arch Large Flange Molded Rubber Expansion Joints

Structural Strength:

- Designed to withstand the most demanding piping system configurations, ensuring reliability under high pressure and load conditions.

Structural Advantages:

- Utilizes a single wide arch design that effectively reduces or eliminates noise and vibration, enhancing system stability.

Wide Applicability:

- Suitable for various industrial sectors, including chemical, mining, and water treatment, meeting diverse operational needs.

Flexible Configurations:

- Available in both open arch and filled arch designs, accommodating different installation conditions and performance requirements.

Protective Mechanism:

- Equipped with a control rod system to prevent excessive displacement in misaligned piping systems, protecting the rubber bellows from damage.

How does the Full-faced Expansion Joints work?

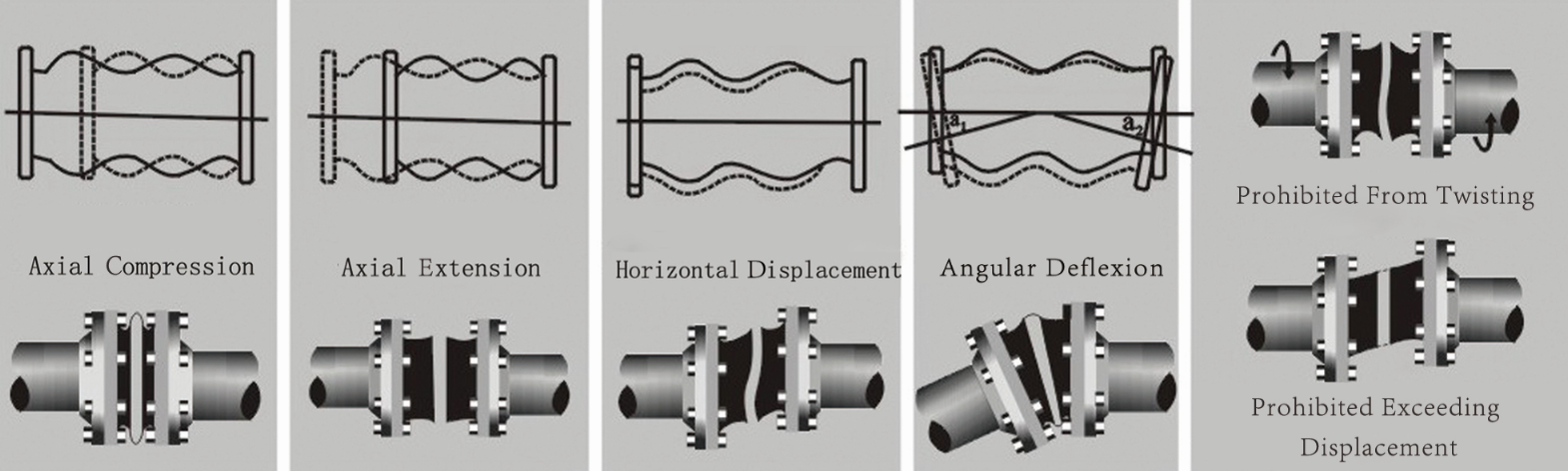

Full-faced expansion joints are designed to accommodate movements in piping systems while providing a complete sealing surface. Here’s how they work:

Design: Full-faced expansion joints typically feature a flat, full-face flange that allows for a direct connection to the piping system. This design helps to evenly distribute the pressure and forces acting on the joint.

Movement Accommodation: These joints are capable of absorbing various types of movements, including axial (longitudinal), lateral (side-to-side), and angular displacements. This flexibility helps to minimize stress on the connected piping and equipment.

Sealing Function: The full-face design ensures a complete seal between the joint and the connecting pipes. This reduces the risk of leaks, which is critical in applications involving liquids or gases.

Vibration and Shock Absorption: Full-faced expansion joints also help absorb vibrations and shocks generated by equipment, enhancing the overall stability and longevity of the piping system.

Installation: They can be easily installed between two flanged connections, making them a practical choice for many piping configurations. Proper alignment and securing of the flanges are essential to ensure effective performance.

Overall, full-faced expansion joints play a crucial role in maintaining the integrity and functionality of piping systems, especially in dynamic environments where movement is expected.

Designs

Single wide arch large flange molded rubber expansion joints are designed to withstand the most rigorous piping system configurations. These joints feature a single wide arch structure specifically aimed at reducing or eliminating common issues such as noise and vibration, misalignment/offset, and turbulence. This series of expansion joints is suitable for a wide range of industrial applications and is available in both open arch and filled arch configurations. Equipped with a control rod system, they prevent excessive displacement that could damage the rubber bellows in misaligned piping systems.

How does a rubber expansion joint displace?

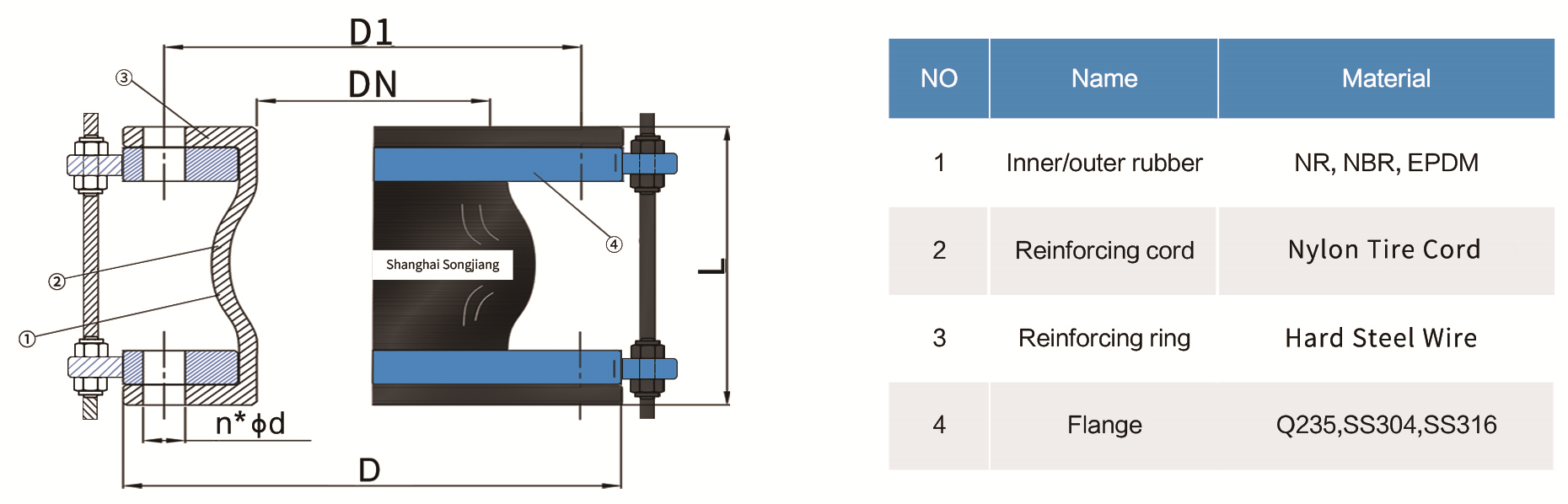

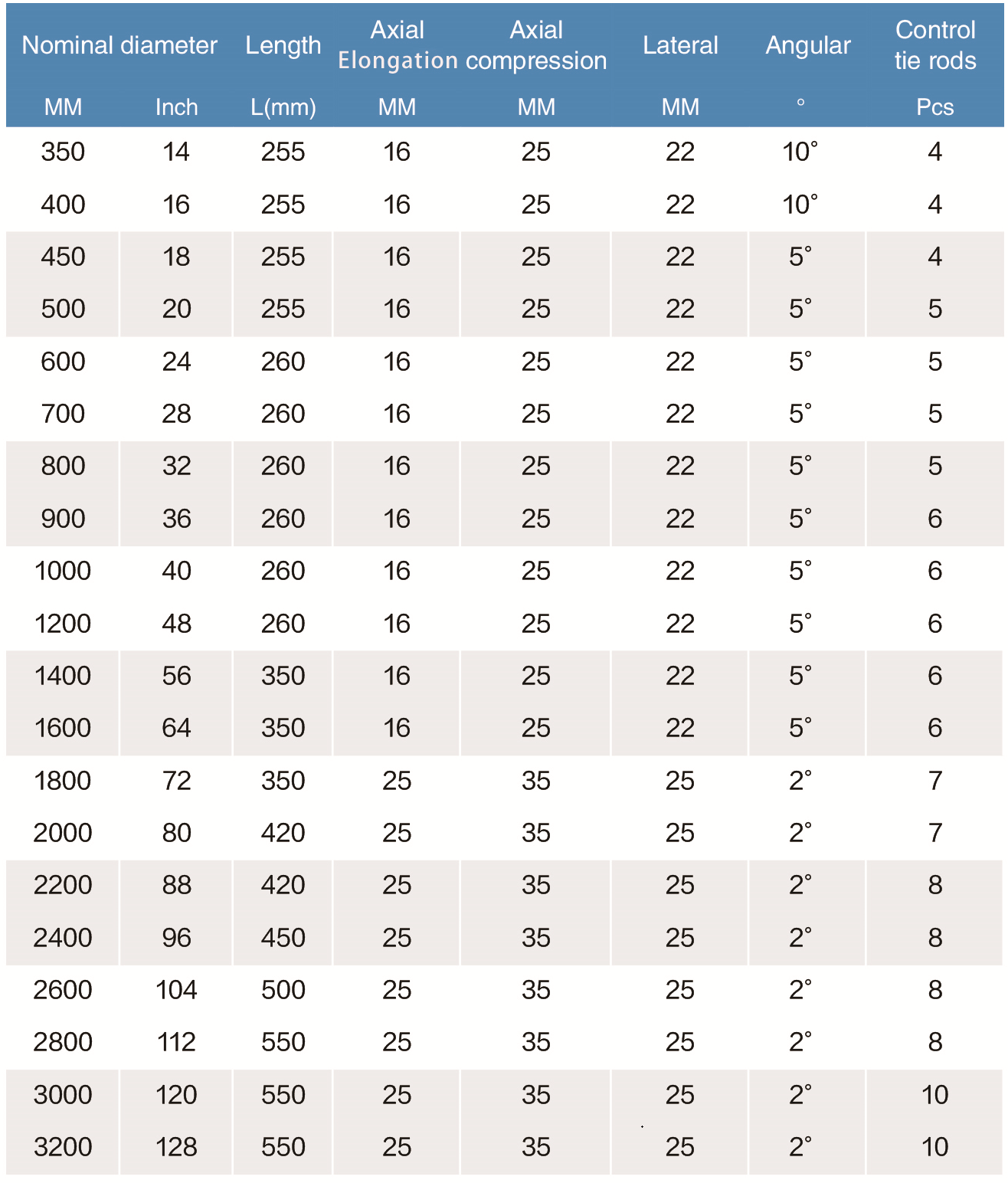

Data of Full Faced Rubber Expanison Joint

Is the data for the above handmade bellow fixed? NO,You can customize it freely.

Customization Options for Flanges and Single Bellow:

Flange Material :

Cast Iron

Carbon Steel

Stainless Steel

Brass

Aluminum Alloy

PVC

Other materials

Standards for Flanges:

ANSI (American National)

DIN (German Standards)

JIS (Japanese Standards)

BS (British Standard)

Chemical Industry Standards

Marine Standards

Custom Non-Standard

Sphere Material :

NR (Natural Rubber)

NBR (Nitrile Butadiene )

EPDM

CR (Chloroprene)

FKM (Fluoro)

Silicone

PTFE Lining