Universal Rubber Expansion Joints

Universal rubber expansion joints offer exceptional flexibility to absorb multi-directional movements, reduce noise and vibration, and protect piping systems from thermal expansion, ground settlement, and mechanical stress. Their lightweight design, long service life, and ease of installation make them one of the most cost-effective solutions for stress relief, misalignment compensation, and extending equipment longevity. We can customize any diameter and length within 5 meters. Special materials, pressure ratings, and structural designs are also available upon request.

Why Are More Projects Choosing Universal Rubber Expansion Joints? (7 Key Benefits You Should Know)

In pipeline engineering, HVAC systems, industrial plants, pump stations, and large mechanical equipment installations, one question often comes up: Why do so many engineers recommend Universal Rubber Expansion Joints? What real value do they bring, and how do they protect your piping system? Here are the 7 most important questions customers always ask — answered clearly and professionally.

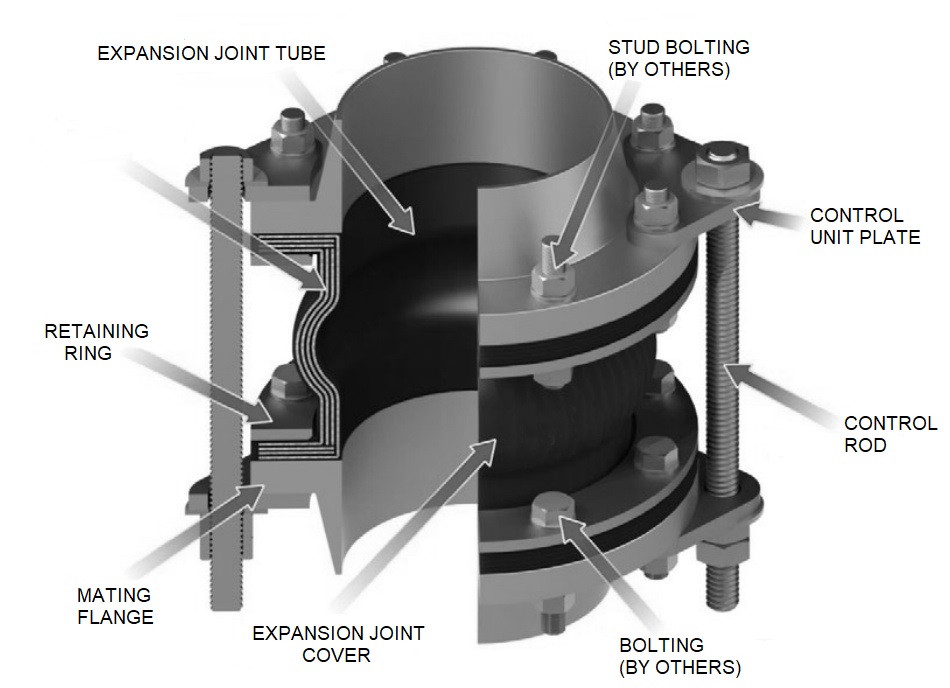

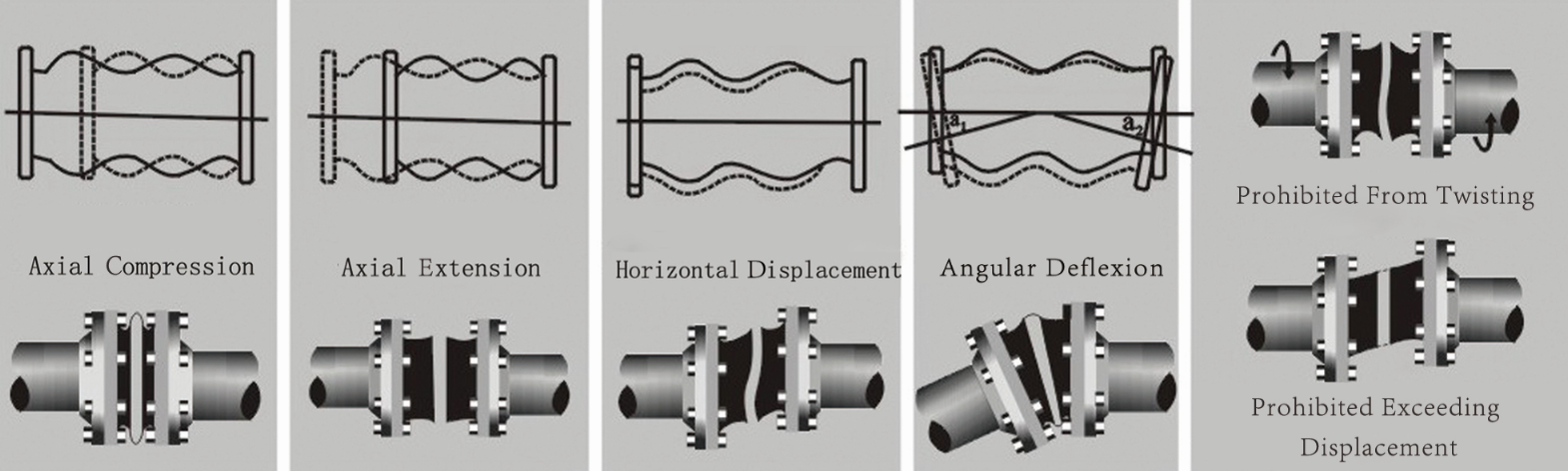

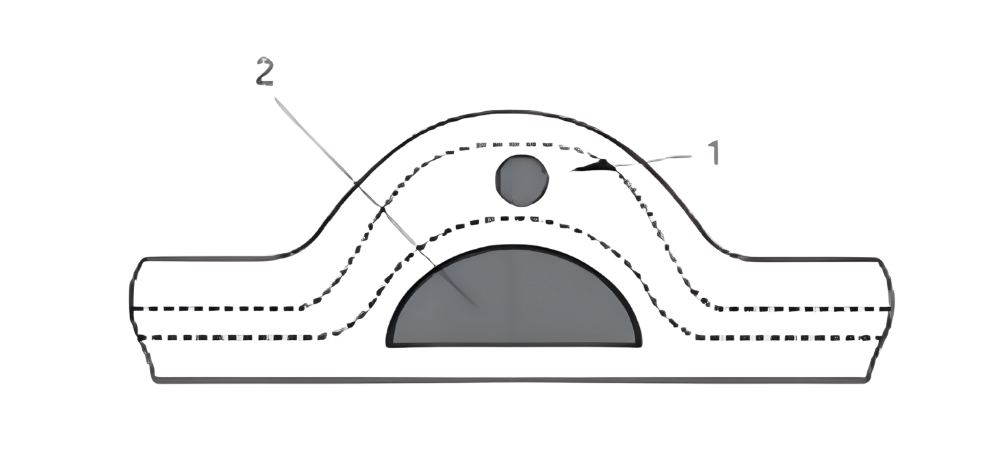

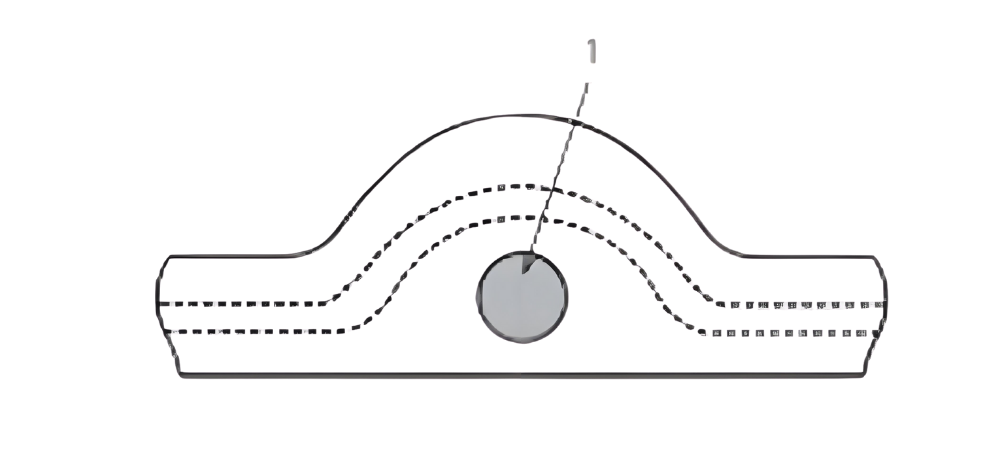

A Universal Rubber Expansion Joint is built with two or more wide molded arches, allowing it to absorb multi-directional movements (axial, lateral, angular), while also reducing noise and vibration.

It’s called “universal” because:

It fits a wide range of applications

It handles large movement requirements

It can replace more complex and costly metallic expansion systems

In one sentence:

A Universal Rubber Expansion Joint = movement absorption + stress relief + vibration control + noise reduction + longer system life

Compared with rigid piping connections, it:

Absorbs thermal expansion and contraction

Protects pipes from excessive stress

Reduces vibration from pumps, compressors, and motors

Lowers operational noise

Improves system stability and safety

Because rubber is naturally flexible.

These joints are constructed from:

Synthetic elastomers (EPDM, NBR, NR, etc.)

Reinforcing fabric layers

Optional metal reinforcements

This combination allows the joint to withstand tens of millions of flexing cycles without failure.

Multi-arch expansion joints:

Allow each arch to independently absorb part of the movement

Have lower stiffness

Require less force to deflect

Offer greater flexibility and stability

In simple terms:

More arches = more flexibility + better movement absorption + longer service life

That’s why they are widely used in pump rooms, long pipeline runs, and thermal fluid systems.

Yes — and this is one of its biggest engineering benefits.

When pressure builds inside the pipeline, the arch area creates thrust force.

Universal expansion joints, due to their low spring rate, effectively reduce this stress and protect anchor points.

For small movement requirements, engineers often choose low-arch designs to minimize force even further.

They are highly recommended in the following situations:

Systems with thermal expansion (hot/cold water, steam, heating)

Pump or compressor outlets with vibration

Piping installations with misalignment

Building or ground settlement concerns

Large projects requiring long service life and high reliability

When looking for a cost-effective alternative to metal expansion joints

Simply put:

If you want a more stable, quieter, and longer-lasting piping system, this should be your first choice.

The 5 most important parameters:

Pressure rating (PN)

Media type & temperature

Number of arches (flexibility & movement capability)

Flange standards (DIN / ANSI / JIS / GB)

Maximum allowable movements (axial / lateral / angular)

If you are unsure which model to choose, we can help recommend the correct type based on your operating conditions.

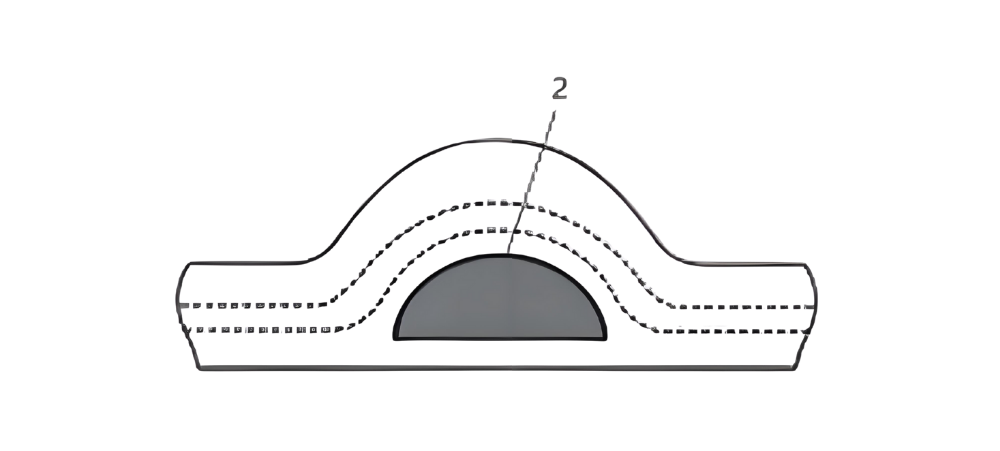

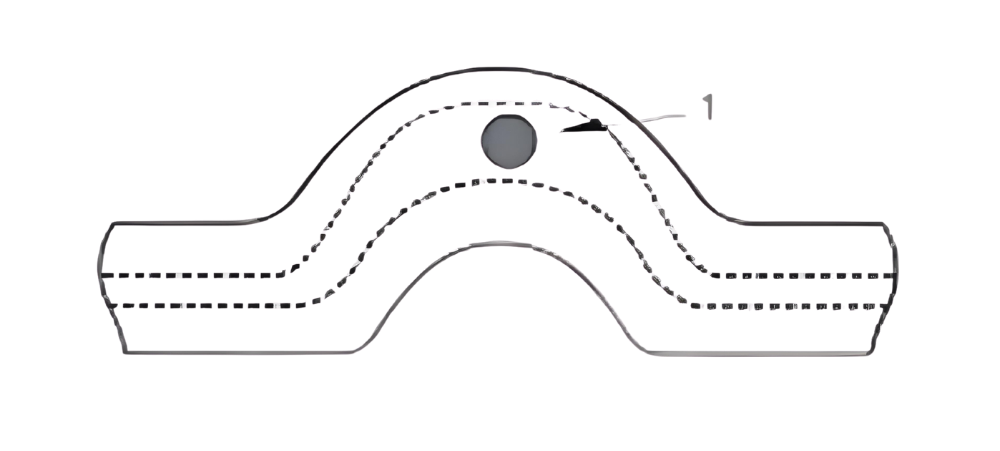

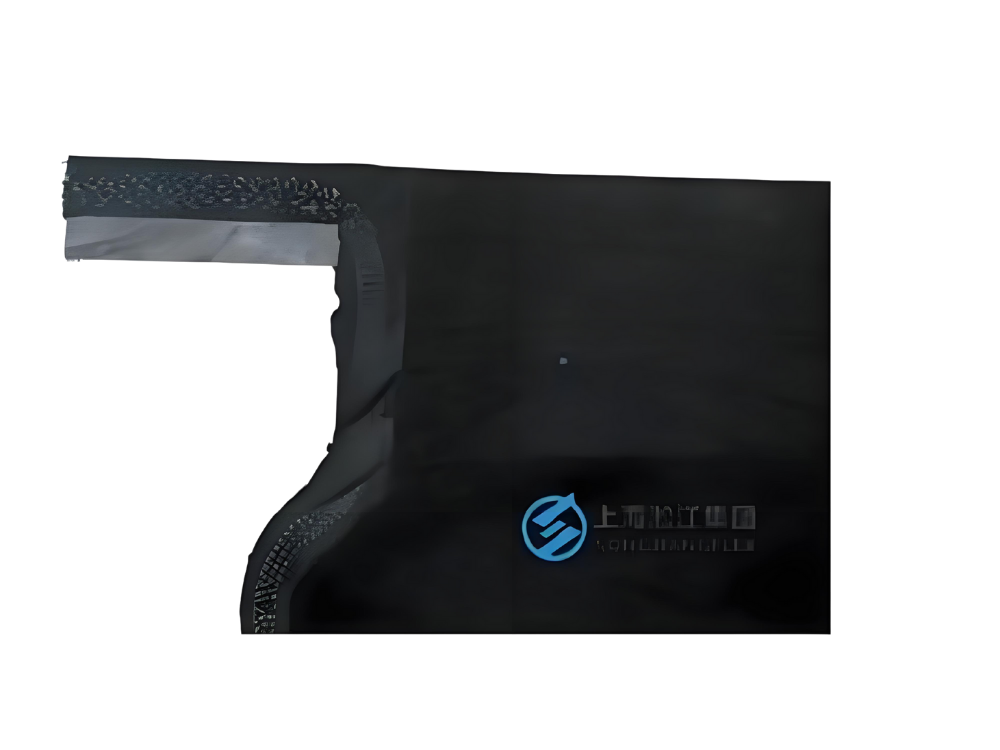

Rubber Bellows Construction &Flange Fixing Technology

Type

Structural

Describe

Standard

Suitable for above-ground conventional pipelines under normal pressure.

Flat inner bore

Suitable for pipelines containing debris or when the medium flow rate is too high: 2 layers of high-molecular rubber.

Built-in steel ring

Suitable for high-pressure applications: 1 steel ring.

Built-in steel ring with flat inner bore

Suitable for high-pressure pipelines containing debris or when the medium flow rate is too high: 1 steel ring + 2 layers of high-molecular rubber.

Inner steel ring with flat inner bore

Suitable for underground, negative pressure, or pipelines containing debris or when the medium flow rate is too high: 1 steel ring.

Type

Structural

Describe

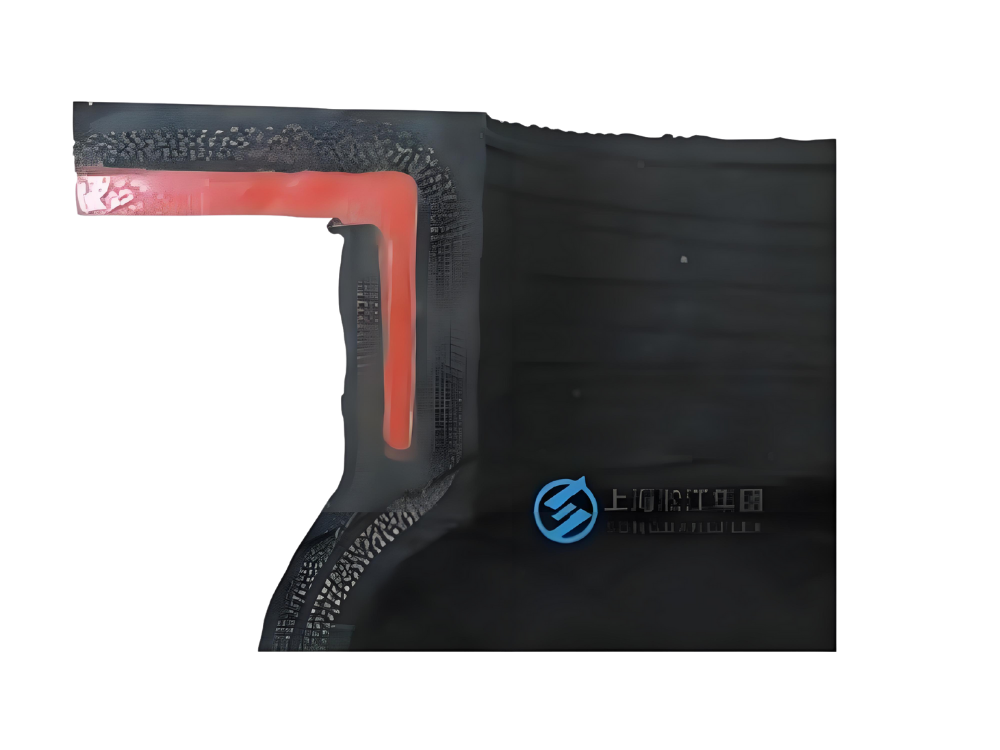

Convex seal

Convex seal with built-in O-ring to prevent pull-off; flange can be rotated for easy installation.

Loose flange

Full-face seal with a larger sealing area to prevent leakage; loose-sleeve split flange requires attention to aligning bolt holes on both pipe ends during installation.

Fixed flange

Flange vulcanized integrally with the sealing face for high pressure resistance and to prevent pull-off.

Built-in O-ring

Sealing face with built-in steel ring, where the steel ring’s outer diameter does not exceed the bolt hole’s inner diameter.

Built-in flange

Sealing face with built-in flange, flange dimensions match the sealing face, suitable for high-pressure applications.

Built-in T-pipe

Flange with connecting pipe, flange vulcanized integrally with the sealing face, with built-in T-pipe, suitable for ultra-high-pressure applications.

Build a High-Performance and Reliable Piping System with Professional Expansion Joints

In modern piping systems, the proper selection and application of expansion joints are critical for ensuring operational stability, durability, and overall system performance. The right expansion joint not only absorbs thermal expansion, vibration, and pipeline movements but also significantly reduces pipe stress, extends equipment life, and guarantees long-term reliability.

With over 30 years of industry expertise, SONGJIANGFLEX applies a systematic engineering approach to provide customized expansion joint solutions for all types of piping systems. Our engineering team leverages Finite Element Analysis (FEA), 3D modeling, and CAD tools to evaluate real operating conditions, pressure levels, and movement requirements, ensuring that every expansion joint perfectly matches the pipeline system for optimal performance and safety margins.

Whether it’s large industrial pipelines, HVAC systems, pump stations, chemical plants, or energy facilities, SONGJIANGFLEX solutions effectively reduce vibration, relieve stress, minimize noise, and enhance overall system stability. We not only provide high-quality rubber expansion joints but also deliver comprehensive technical support, ensuring each system operates reliably and efficiently over its entire lifecycle.

Choose SONGJIANGFLEX – for safer, more stable, and higher-performing piping systems!