Cylindiric Vibration Mount

The cylindrical vibration mount is made of conductive NBR and zinc-coated metal. Applications include air compressors, diesel engines, gasoline engines, water pumps, welding machines, fans, air conditioners, generators, and electromechanical equipment.Rubber hardness and rubber compounds can be adjusted according to customer applications.

What are the Unique Features of Cylindiric Vibration Mount?

1.Elastomer Parts: Conductive NBR, black

2.Metal: DIN EN 10111-98, zinc coated; available in stainless steel

3.Working Temperature Range: -30°C/+80°C

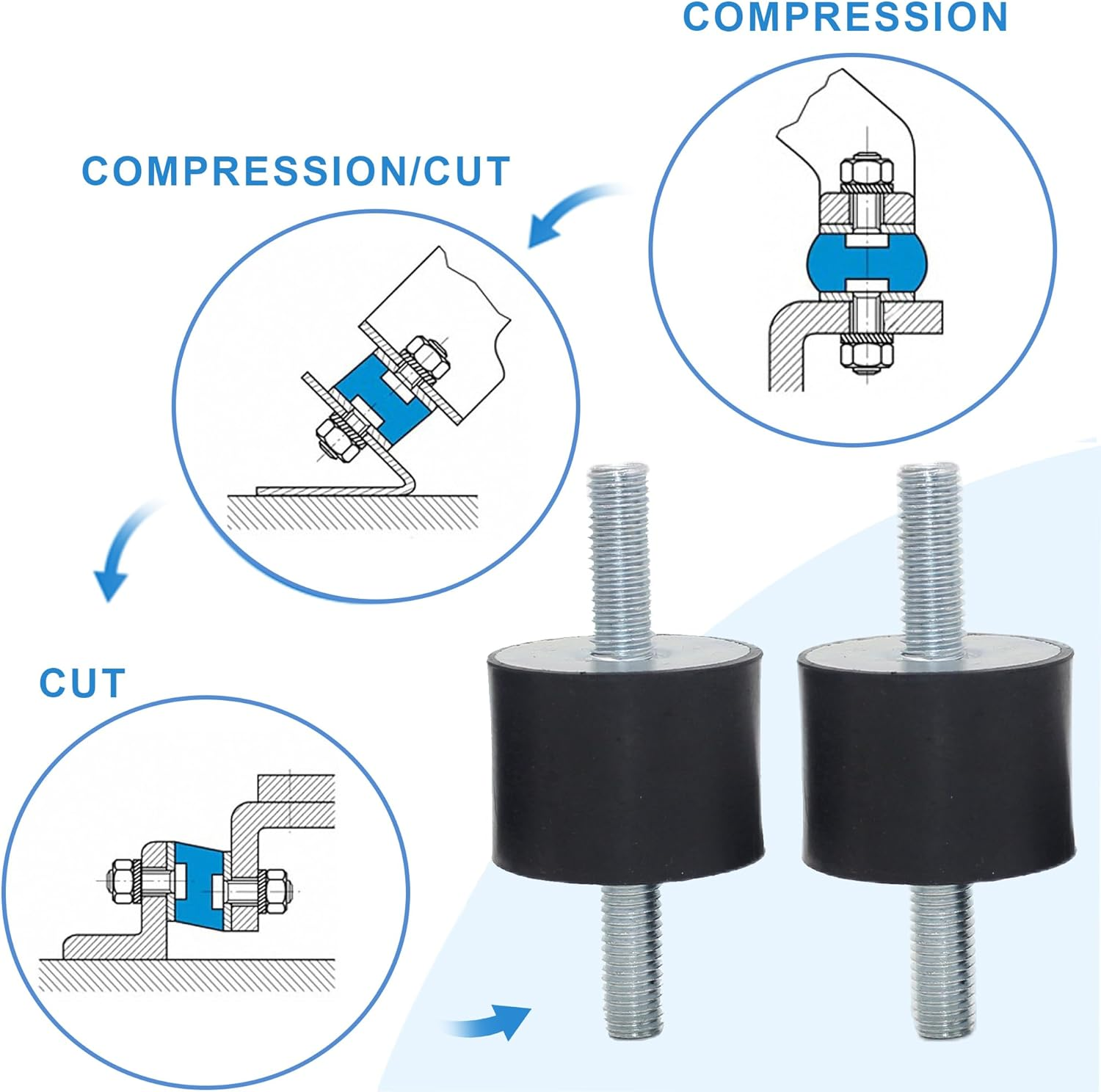

4.Features: Axial stiffness is greater than radial stiffness, capable of withstanding both compression and shear forces

5.Applications: Air compressors, diesel engines, gasoline engines, water pumps, welding machines, fans, air conditioners, generators, electromechanical equipment, etc.

6.Rubber hardness and rubber compounds can be adjusted according to customer applications.

How does the Cylindiric Vibration Mount work?

Working Mechanism of the Cylindrical Vibration Mount

- Material Composition: Made from conductive NBR and zinc-coated metal, the mount is durable and capable of handling various environmental conditions.

- Stiffness Properties: With greater axial stiffness than radial stiffness, the mount can absorb both compression and shear forces, enhancing its ability to mitigate vibrations.

- Temperature Range: It functions effectively within a temperature range of -30°C to +80°C, making it suitable for diverse applications.

- Vibration Isolation: When machinery operates, the mount compresses and flexes to absorb vibrations, preventing them from transferring to the supporting structure. This helps maintain stability and reduces wear on both the equipment and the surrounding environment.

- Adjustable Hardness: The ability to customize rubber hardness and compounds allows the mount to be tailored to specific applications, optimizing its performance for different types of machinery.

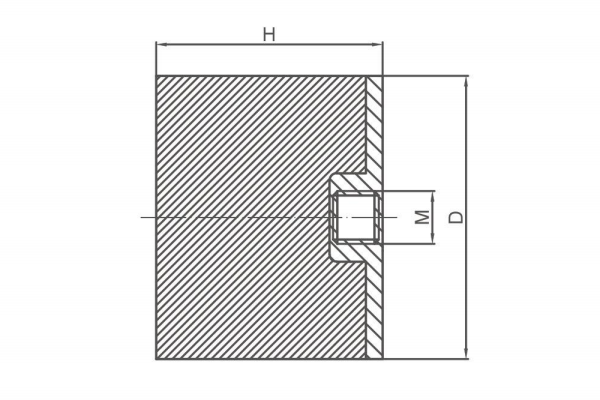

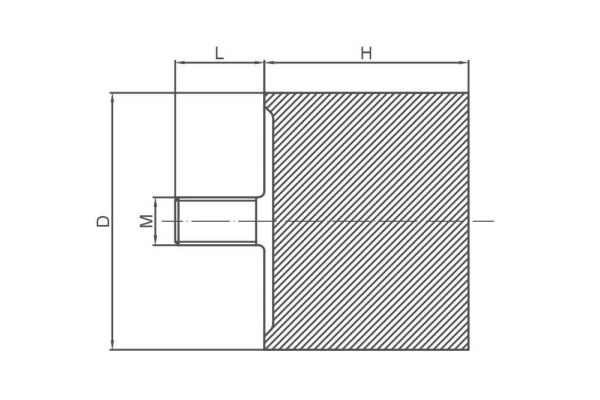

Diagram for Cylindiric Vibration Mount installation:

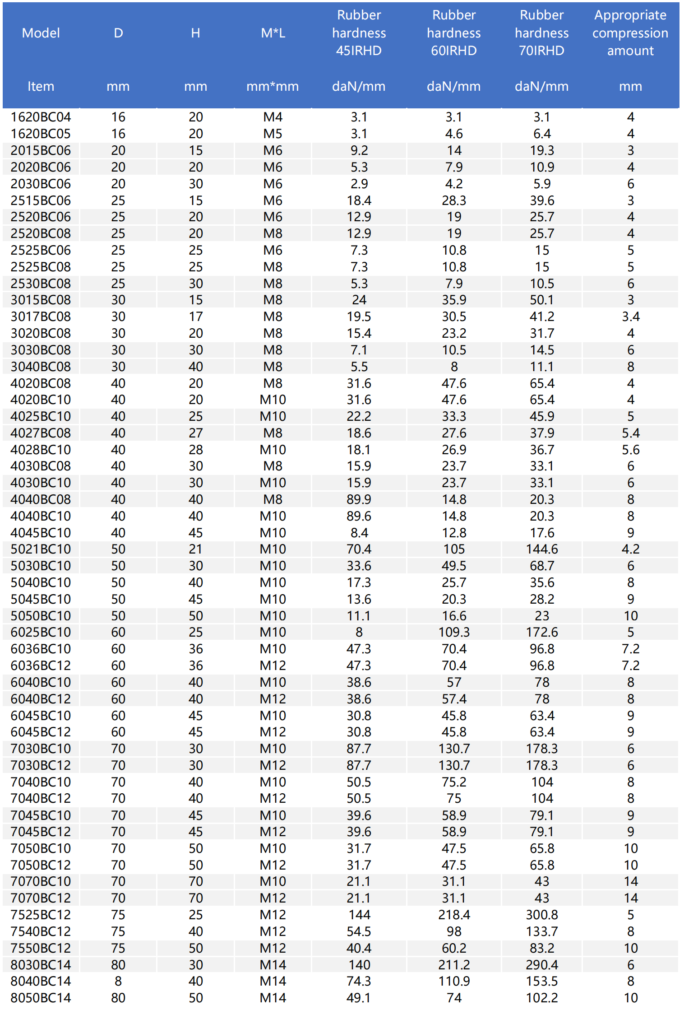

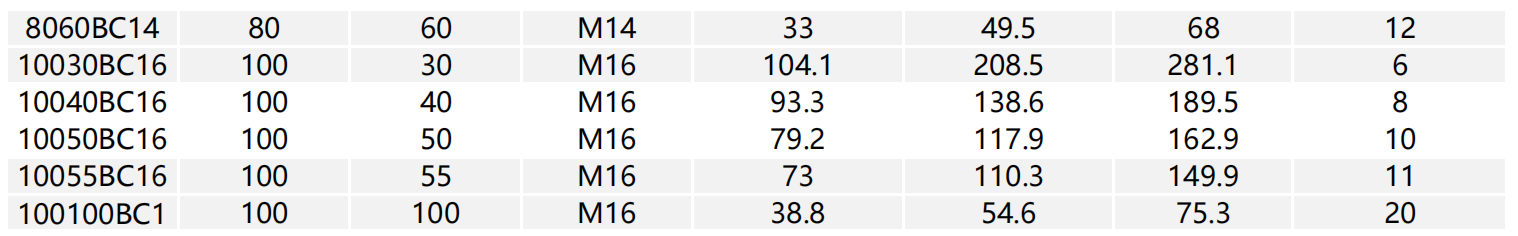

Data of Cylindiric Vibration Mount