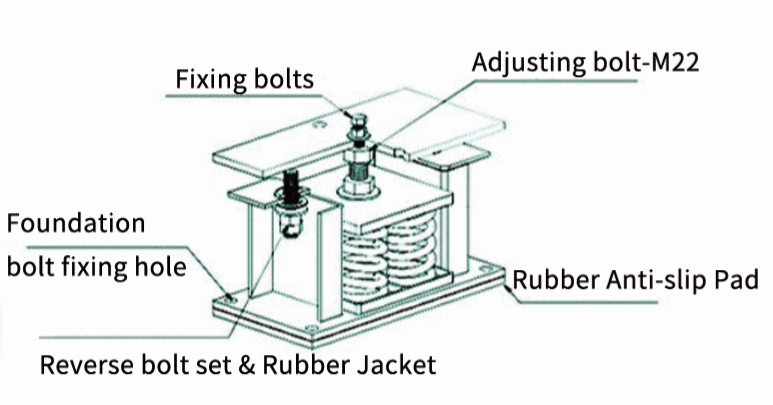

SHM Type Adjustable Spring Mount

Main Uses of Adjustable Spring Vibration Isolators: Chillers, generator sets, exhaust fans, cooling towers, piping systems, transformers, etc. The outer frame is treated with hot-dip galvanized surface treatment, while the spring surface is treated with powder coating, offering excellent rust resistance, both of which have passed ASTM B-117 and CNS 8886 salt spray tests.

What Are the Unique Features of SHM Spring Mount?

1.The spring diameter is greater than 0.8 times the height under compression to the rated deflection, and the compression force when the spring is compressed exceeds 50% of the rated deflection.

2.The spring undergoes heat treatment and stress relief processes, ensuring excellent fatigue resistance, with a recovery rate of over 99%.

3.The design features a lock bolt that maintains a 12mm gap with the outer frame to prevent vibration transmission.

4.A 6mm thick synthetic rubber pad at the bottom provides sound absorption and slip resistance.

5.The cushion design allows for a fixed usage height and simple installation.

6.The SHM type spring vibration mount is designed with different numbers of springs based on the load capacity. Common configurations include 1 set, 2 sets, 4 sets, 6 sets, and 9 sets of springs, meeting the needs of various weighted machinery and precisely enhancing vibration reduction effectiveness.

How does the SHM Type Adjustable Spring Mount work?

The SHM type spring vibration Mount is designed with a low frequency value and undergoes special treatment for excellent weather resistance and effective vibration isolation. Both the top and bottom feature non-slip, wear-resistant imported rubber, along with fixed bolts, significantly enhancing safety. It is installed beneath the required machinery and can be adjusted for level and height based on actual needs.

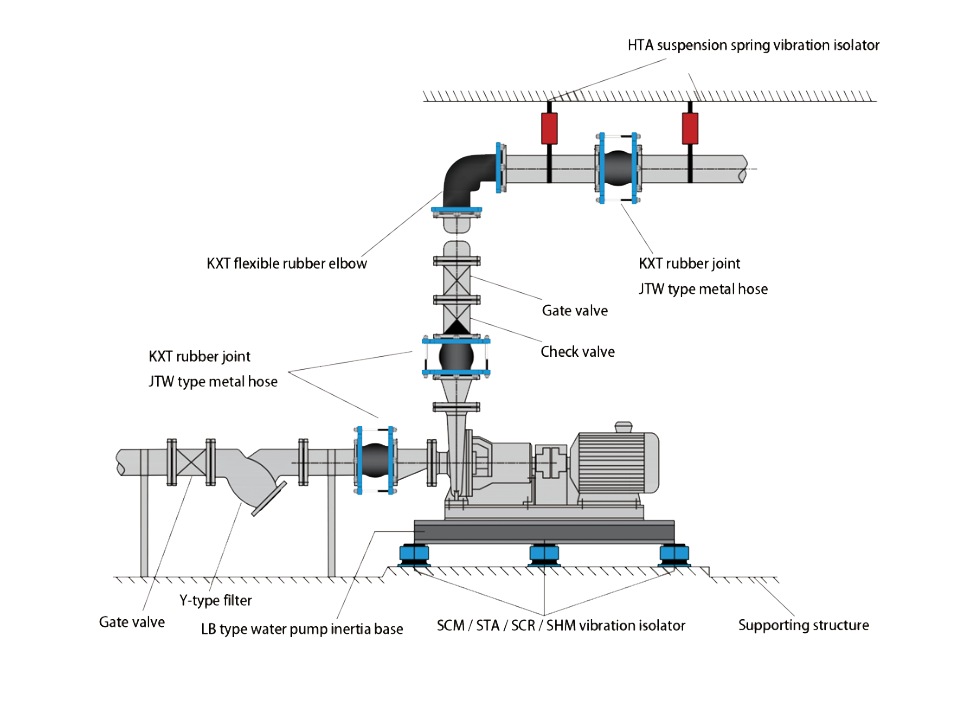

Diagram for vibration Isolator installation:

Spring vibration isolators are commonly used for pump isolation and offer several advantages: they provide excellent low-frequency vibration isolation due to large static deflection and low natural frequency, are resistant to corrosion from oil and water while remaining unaffected by temperature changes, and do not suffer from aging or creep deformation, ensuring long-term performance.

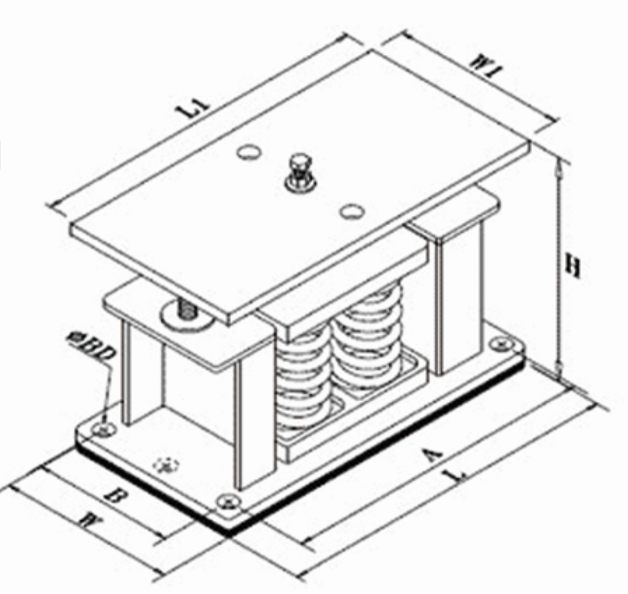

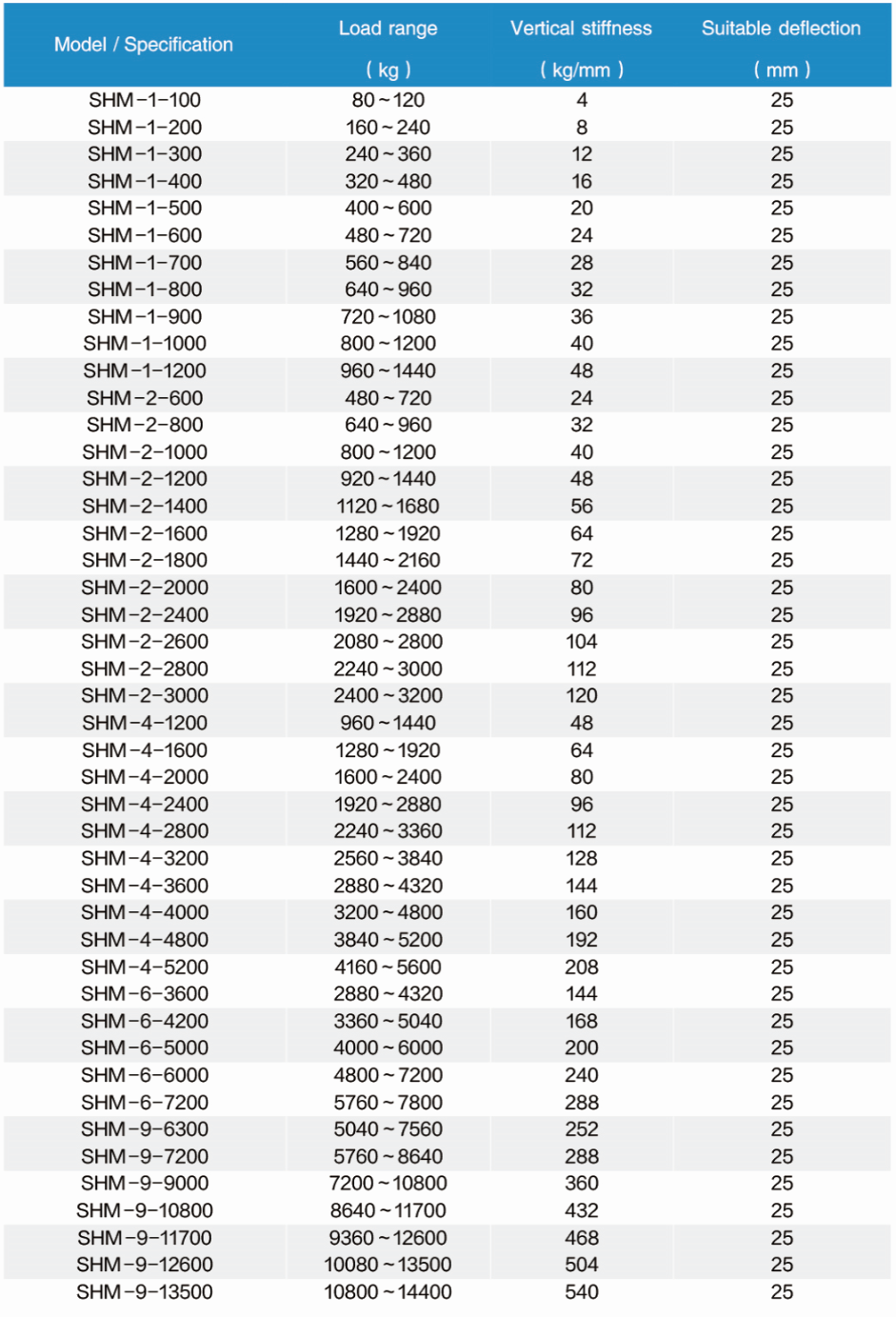

Data of SHM Type Adjustable Spring Mount