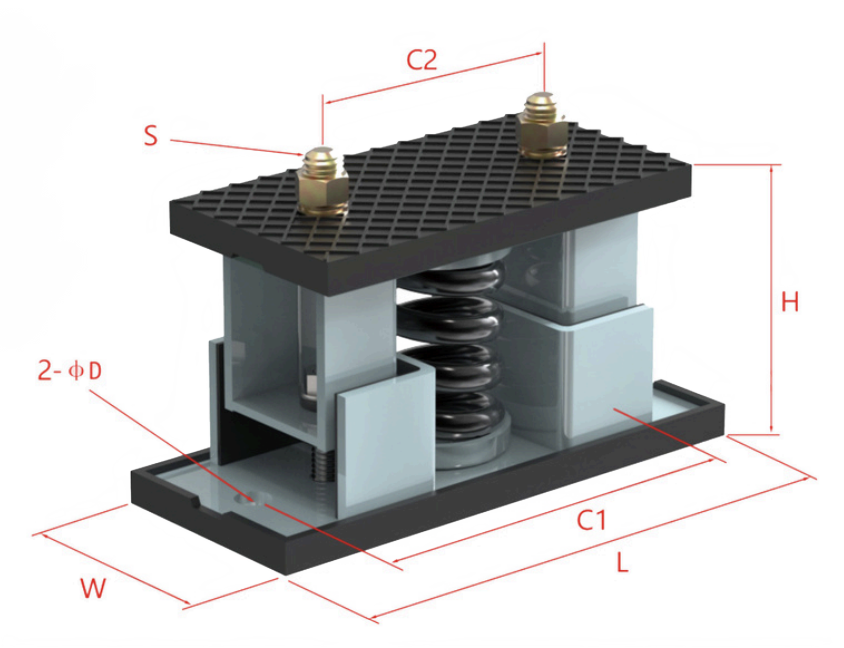

WM Type Seismic Spring Isolator

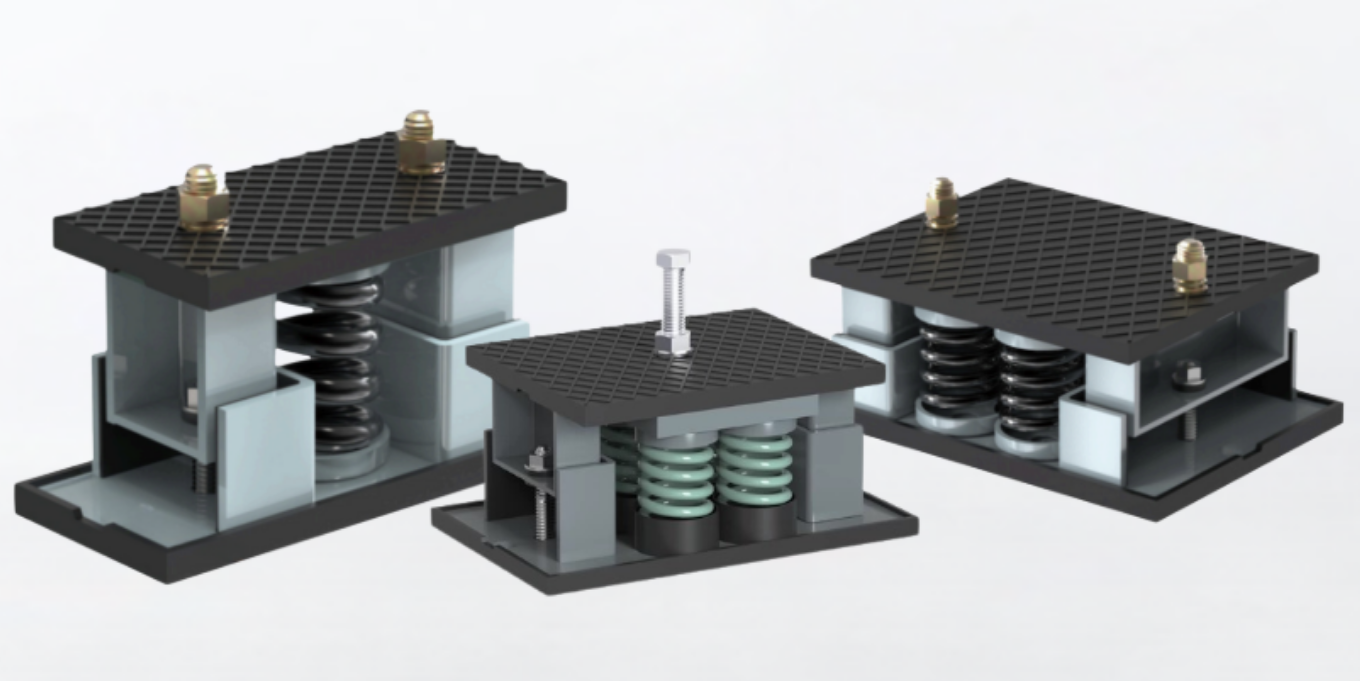

The SM-type seismic vibration isolator features upper and lower side plates with connecting rods that form an integrated structure, effectively preventing equipment from toppling during earthquakes. Its channel-shaped plates and rods provide all-round restraint, limiting tilt within 25°. The isolator offers excellent resistance to lateral and tensile forces, ensuring durability under seismic conditions. The precisely designed plate clearance also helps prevent equipment from tilting under strong vibrations.

What are the main features of seismic vibration isolators?

Anti-toppling Design: Equipped with side plates and connecting rods to prevent equipment from tipping during earthquakes.

Tilt Limitation: Effectively controls tilt within a 25° range for enhanced safety.

All-Directional Restraint: Channel-shaped side plates provide full-range equipment support.

Lateral & Tensile Resistance: Strong resistance to side forces and tension prevents damage under seismic loads.

Integrated Structure: Top and bottom plates form a single unit, increasing structural stability.

Shock Absorption: Maintains effective vibration isolation while offering seismic protection.

Why use seismic series vibration isolators?

WM seismic series vibration isolators are designed to control the movement of equipment, piping, and duct systems during an earthquake. Before selecting seismic isolators, it’s important to understand how seismic forces act and how to properly restrain equipment and systems in response.

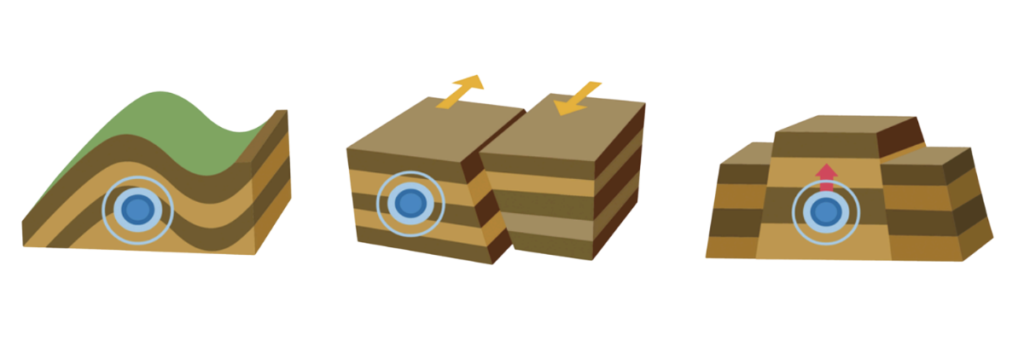

Earthquakes occur when faults in the Earth’s crust shift or slip. Structures that span these faults can be severely damaged, no matter how well-designed. However, most earthquake effects are not limited to the fault line — the motion generates seismic waves that travel outward, creating complex and unpredictable vibrations.

Seismic forces can be horizontal, vertical, or rotational, and their direction, intensity, and duration are impossible to predict. To resist these forces, building components must be securely connected to the structure. The goal is for equipment to move with the building during an earthquake, rather than becoming detached.

Since we cannot predict the direction of seismic forces, it’s essential to support and restrain equipment and piping systems in multiple directions. Floor-mounted equipment with vibration isolators should also be restrained using seismic isolators that prevent tipping or sliding.

In the past, equipment like pumps, chillers, and cooling towers were installed with minimal or no consideration of seismic effects. Now, with extensive research and updated building codes, seismic restraints are required to ensure systems remain intact during earthquakes.

It has been proven that the cost of properly restraining equipment is significantly lower than repairing earthquake-damaged systems. Even if a building survives, unrestrained mechanical systems can render it unusable.

Proper sizing, placement of restraints, and accurate calculation of anchor bolt forces are critical. WM seismic series vibration isolators are engineered to provide the strength and isolation needed to keep systems secure and operational during seismic events.

How to install an anti-seismic spring vibration isolator?

To install an anti-seismic spring vibration isolator, first ensure the model matches design specs and the installation surface is flat and sturdy. Install the isolator vertically, aligning the spring axis with the equipment’s load direction. Securely bolt both ends to the equipment and foundation, avoiding pre-compression of the spring. Finally, check that all bolts are tight, the isolator is vertical, and the spring moves freely without obstruction

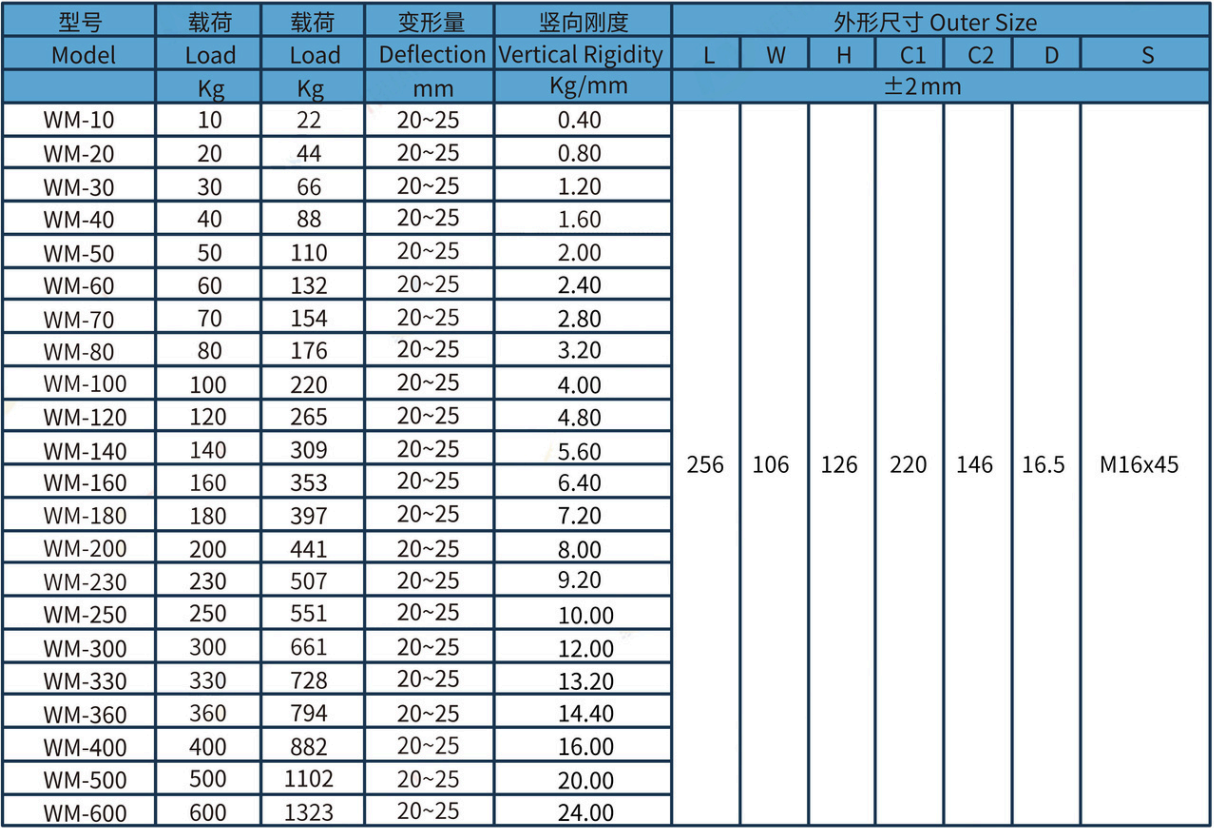

Data of WM Type Seismic Spring Isolator