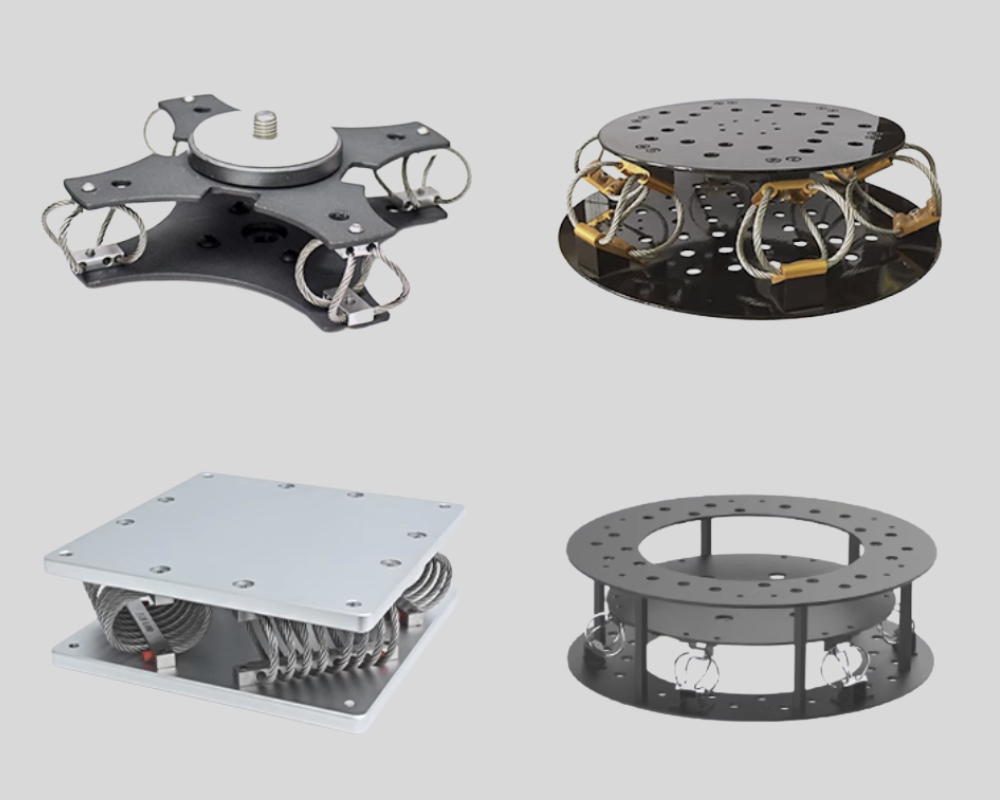

Stainless steel Wire Rope Isolators

The SS Wire Rope Isolators features a full metal structure for high reliability and long lifespan (15-20 years). With high damping ratio, low peak amplification, and excellent anti-aging and corrosion resistance, it operates in a wide temperature range of -180° to +300°. The product is highly adaptable and widely used in industries such as shipborne, automotive, aerospace, machinery, electronics, and photography equipment. It ensures effective vibration, shock, and noise control to meet industry standards. Custom designs are available upon request.

304 stainless steel clamp and wire rope offer high damping and low natural frequency, designed for use in vehicles and ships to provide shock absorption and energy dissipation. With load capacity ranging from 1.4 to 2000 kg, they are suitable for military, chemical, aerospace, communication systems, medical equipment, mobile electronics, and other applications requiring vibration isolation, buffering, and energy absorption.

Wire Rope Isolators Polycal isolators are multidirectional wire rope isolators that provide protection against harsh shock and vibration during transport and handling of sensitive equipment. Properties All metal Construction Multidirectional Simple Fixation Interface Exceptional reliability and lifetime Superior temperature range: -290 ° F to + 570 ° F .Static loading per isolator: 0.22 lbf to 1.1 kipf .Damping ratio: 15-25% (viscous equivalent).

Polycal wire rope isolators are multidirectional, all-metal devices designed to protect sensitive equipment from shock and vibration during transport and handling. With a temperature range of -290°F to +570°F, static load capacities from 0.22 lbf to 1.1 kipf, and a damping ratio of 15-25%, these isolators offer exceptional reliability and long lifespan. They are widely used in sectors such as defense, aerospace, nuclear, oil, research, railways, and medical applications.

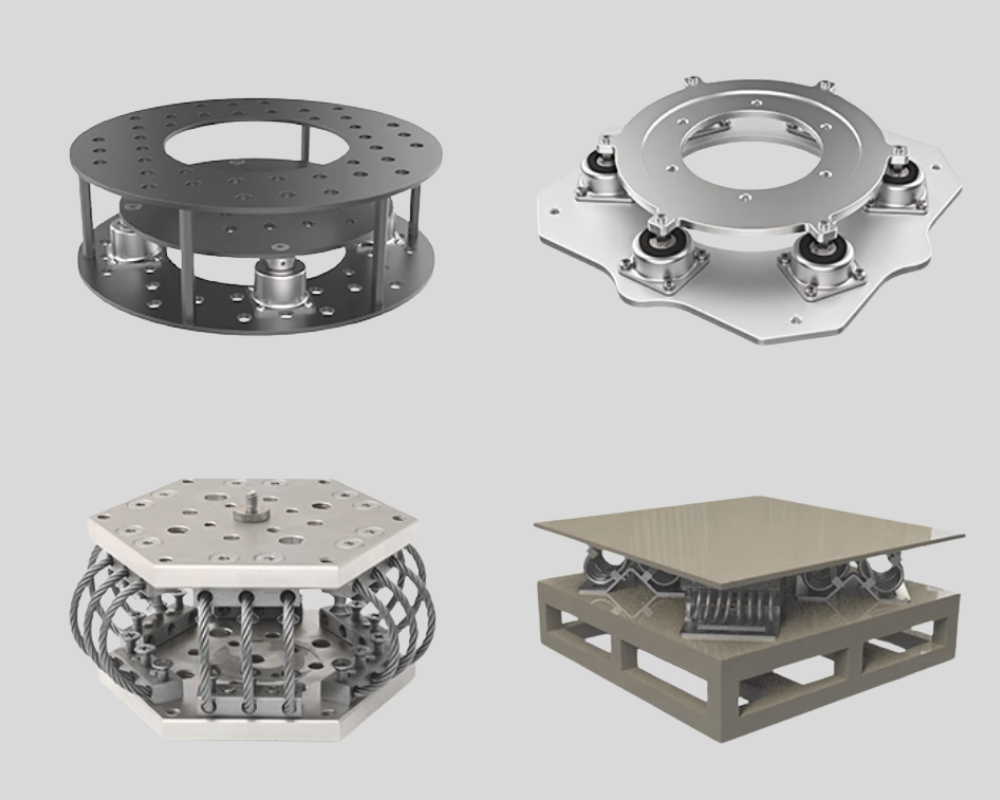

Made from 6061 aerospace aluminum and stainless steel, supports 0–55 kg. Lightweight, corrosion-resistant, and easy to install. Ideal for vehicle-mounted systems, aerial photography, and precision instruments.

The platform can be equipped with various models of wire rope vibration isolators, with a load range of 0–55 kg. It can be customized based on the customer’s installation method and shock load requirements.

The platform can be equipped with various models of wire rope vibration isolators, with a load range of 0–55 kg. It can be customized based on the customer’s installation method and shock load requirements.

Raw Materials

Production process

Once the wire ropes are produced, CNC (Computer Numerical Control) high-precision cutting is employed for exact measurements and custom lengths. This advanced technology ensures that each section of the wire rope is cut to precise specifications with minimal tolerance. CNC cutting provides sharp, clean edges and consistent dimensions, reducing the risk of errors and improving the overall quality of the wire ropes.

In some cases, the wire ropes undergo an annealing process, where they are heated and then slowly cooled to relieve stress and enhance their ductility. This step can improve the rope’s flexibility and resistance to fatigue.

Surface Finishing

The stainless steel wire rope may undergo additional surface treatments, such as polishing or passivation, to further improve its resistance to corrosion, making it ideal for harsh environments such as marine, aerospace, and industrial applications

Quality Control

Each wire rope is carefully inspected and tested for quality assurance. This includes checking for tensile strength, flexibility, corrosion resistance, and overall performance. Any defective ropes are discarded or reprocessed to ensure the final product meets industry standards.