SWR Series Wire Rope Isolator

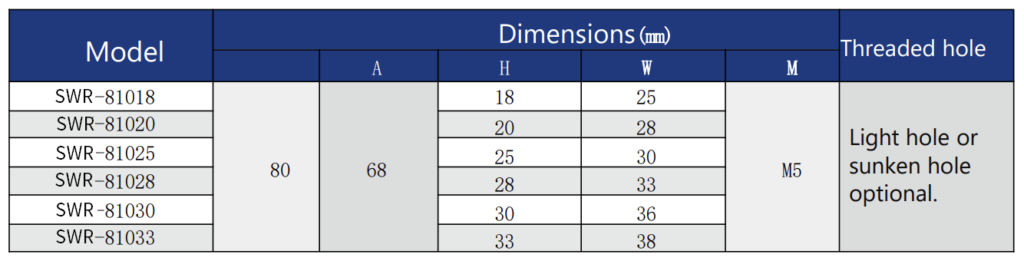

The SWR-type Stainless Steel Wire Rope Vibration Damper Consists of 304 stainless steel clamps and 304 stainless steel wire ropes, offering high damping performance and low natural frequency. It is designed specifically for vehicles and vessels, providing cushioning and energy absorption. Load capacity ranges from 1.4 to 2000 kg, making it suitable for applications in ships, military, chemical, and aerospace equipment control systems, as well as transmission protection devices, communication devices, medical equipment, mobile electronic instruments, and other scenarios requiring vibration isolation, buffering, and energy absorption.

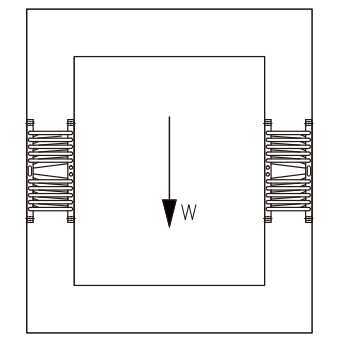

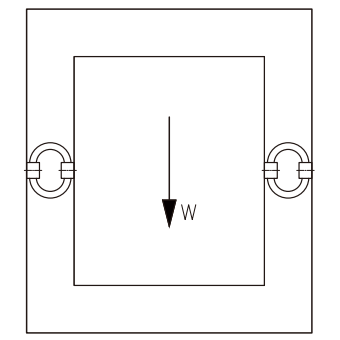

Can be installed vertically or at a 45-degree side angle / Corrosion-resistant and high-temperature resistant.

Ideal Vibration Isolation Solution for Small Equipment: SWR-1-type Steel Isolator

The SWR-1-type wire rope isolator is designed and produced for small electromechanical equipment. It is made of stainless steel plates and stainless steel wire ropes, featuring a nonlinear design. It provides excellent shock resistance, strong weather resistance, and operates at temperatures ranging from -70°C to 200°C. It is oil-resistant, fog-resistant, and does not age. Under various operating conditions, it shows no significant resonance. Its structure is lightweight and easy to install, making it an ideal vibration isolation device for small electromechanical equipment.

Applicable Equipment: On-board hard drives, small vehicle-mounted devices, small marine devices, fire protection equipment, communication equipment, cabinets and enclosures, electrical control cabinets, photographic equipment, drones, and more.

Load Range: 0.9-8.8KG.

Advantages: Rugged all-metal construction, high inherent damping, no maintenance required, long product lifetime, excellent resistance to chemicals, seawater, ozone, radioactivity, and UV light.

SWC Gimbal Camera Crane Shock Absorber Wire Rope Isolator

The SWC-type vibration isolation gimbal’s upper and lower plates are made of 6061 aerospace aluminum, with an anodized surface treatment. Paired with a wire rope shock absorber, it has an attractive appearance, long service life, and excellent vibration damping performance. It can accommodate various models of wire rope shock absorbers, with a wide load range (0-55kg). It is suitable for a variety of applications, including vehicle-mounted cameras, aerial photography, communication devices, electronic sensing equipment, mobile electronic instruments, surveillance cameras, camera cranes, and more. Custom shapes and load parameters can also be tailored according to customer requirements.

Applicable Equipment: On-board hard drives, small vehicle-mounted devices, small marine devices, fire protection equipment, communication equipment, cabinets and enclosures, electrical control cabinets, photographic equipment, drones, and more.

The gimbal can be equipped with various models of wire rope dampers, with a load range of (0-55Kg), and the shape and load parameters can be customized according to customer requirements.

Vehicle-mounted wire rope isolators, such as the Shadow vibration-damping gimbal camera crane shock absorber, provide shock absorption, vibration isolation, and stabilization.

What are the features of SWR Series Wire Rope Isolator?

Key Features of SWR Series Wire Rope Isolator:

-

High Damping Performance:

- Provides superior damping characteristics, reducing vibration and noise in harsh environments.

-

Low Natural Frequency:

- Designed with a low natural frequency, making it highly effective at isolating low-frequency vibrations.

-

Durability:

- Made from 304 stainless steel wire ropes and clamps, ensuring resistance to corrosion and long-term reliability, even in challenging conditions.

-

Wide Load Capacity:

- Available in a broad load range from 1.4 kg to 2000 kg, making it versatile for different weight-bearing applications.

-

Cushioning and Energy Absorption:

- Excellent at absorbing shock and providing cushioning, reducing impact stresses on sensitive equipment.

-

Corrosion Resistance:

- Constructed from stainless steel materials, ensuring resistance to corrosion, rust, and wear, ideal for marine, military, and industrial environments.

-

Applications in Various Sectors:

- Suitable for use in marine vessels, military and aerospace equipment, chemical industries, medical devices, communication systems, and electronic instruments that require vibration isolation and protection.

-

Compact Design:

- The isolator’s compact and lightweight design allows for flexible installation in space-constrained environments.

-

Customizable Options:

- Customizable specifications available based on specific application requirements, including load capacity, size, and material choices.

-

Effective Vibration Isolation:

- Excellent performance in applications requiring isolation from machinery vibrations, improving the longevity and operational efficiency of sensitive equipment.

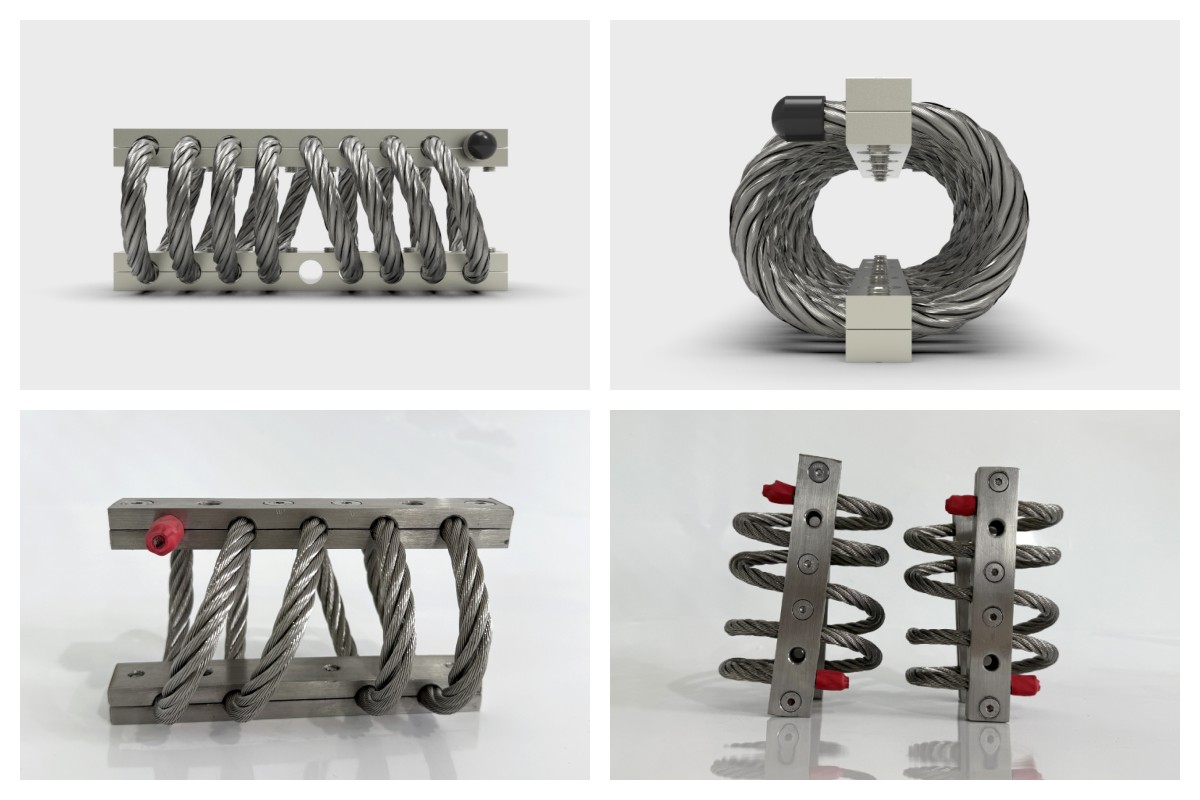

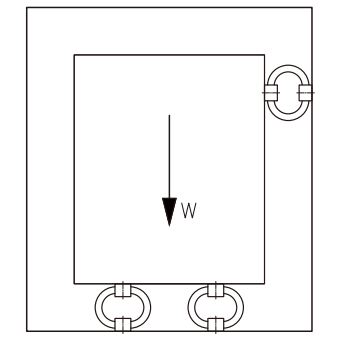

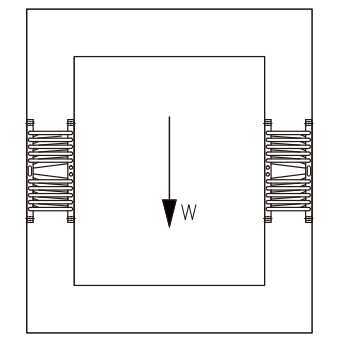

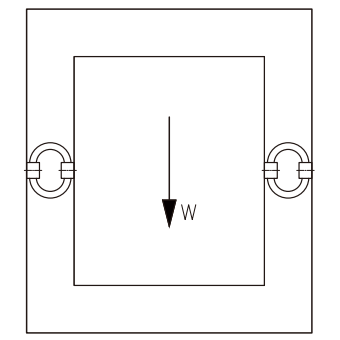

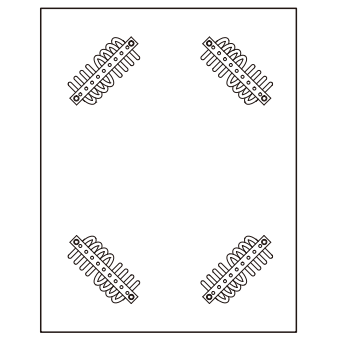

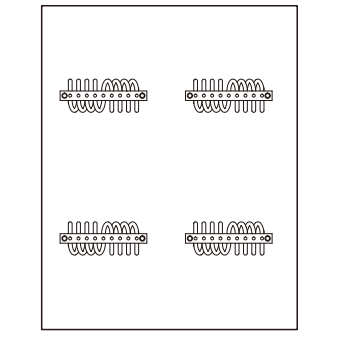

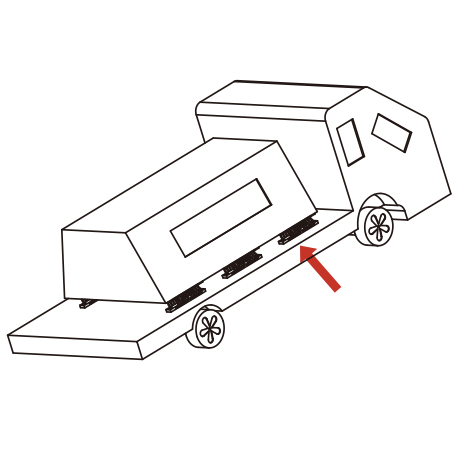

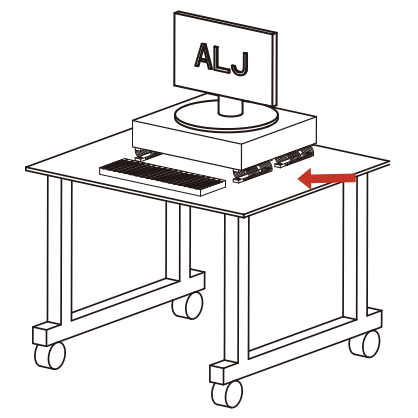

Common installation methods for steel wire rope vibration isolators include:

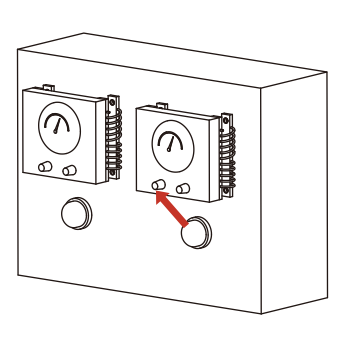

Steel wire rope isolator application examples

Current and Voltage Meter Vibration Isolation

Vehicle CD Player Vibration Damping

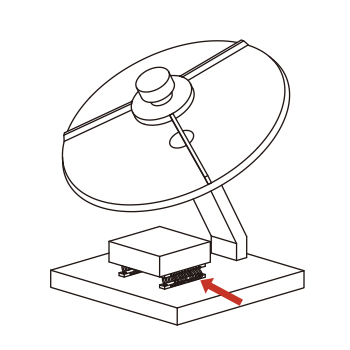

Satellite Receiver Vibration Isolation

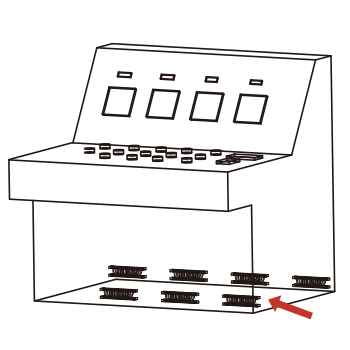

Control Panel Vibration Reduction and Isolation

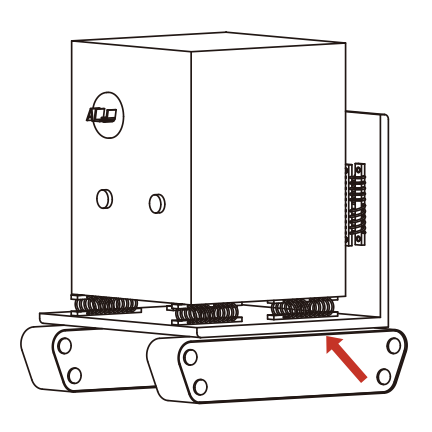

Unmanned Exploration Vehicle Vibration Damping

Vibration Damping for Transportation of Vehicle-Mounted Equipment

Vibration Damping for Mobile Carts

Computer Vibration Damping-Steel Wire Rope Isolator

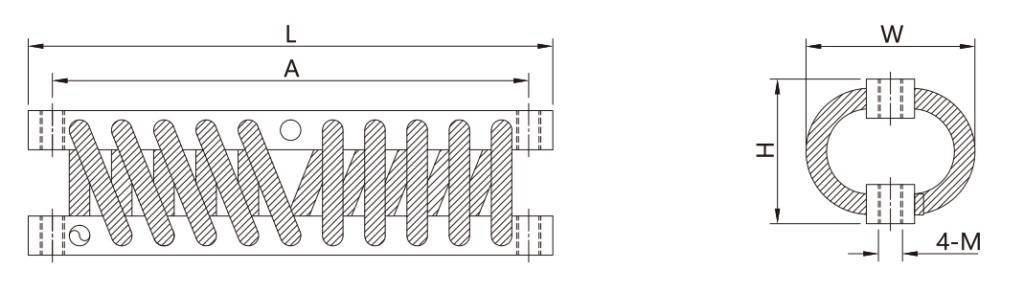

SWR- 810 Series Antisymmetric (Pressed)