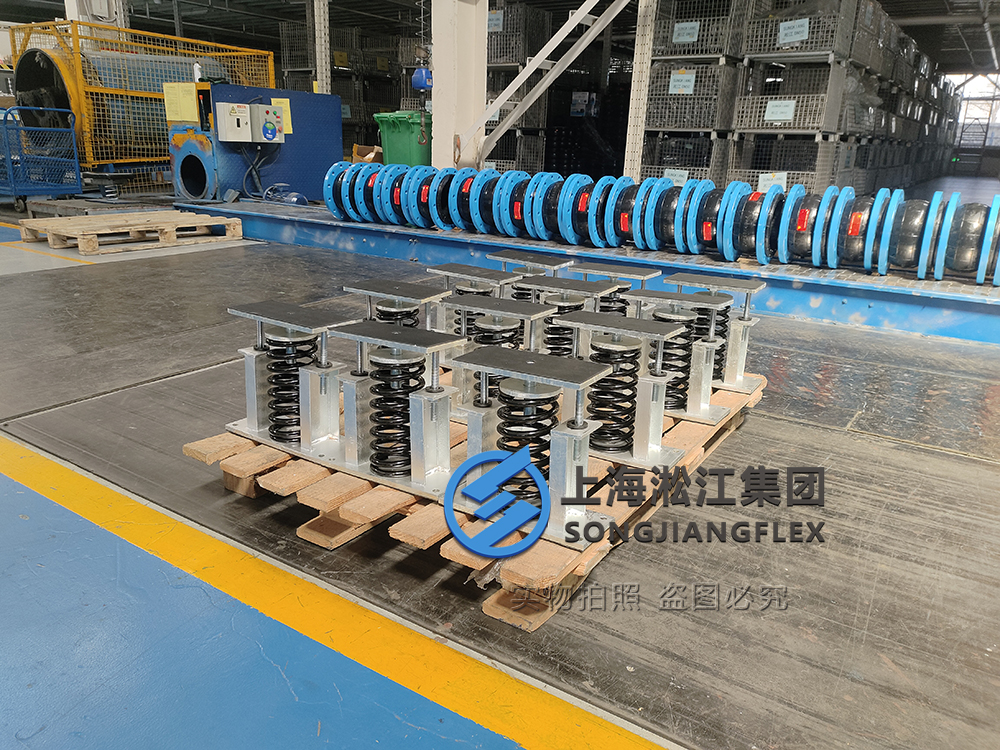

Vibration issues are common in various industries, and a custom 50mm deflection spring vibration isolator can effectively solve these problems, improving equipment stability and longevity.

Definition and Applications of 50mm Deflection Spring Vibration Isolator

The 50mm deflection spring vibration isolator is widely used in industrial equipment, significantly improving mechanical stability by isolating vibrations. This isolator combines springs and rubber to absorb and mitigate the transmission of vibrations, reducing damage and noise pollution, ensuring stable operation of equipment for an extended period.

Advantages of 50mm Deflection Design

The 50mm deflection spring vibration isolator can significantly reduce equipment vibrations, making it ideal for environments with high-frequency vibrations. By increasing deflection, it absorbs vibration energy more effectively, reduces noise, and extends equipment life. It is particularly suitable for HVAC systems, water pumps, compressors, and other high-vibration applications, ensuring equipment runs efficiently.

Design Advantages of the 50mm Deflection Spring Vibration Isolator

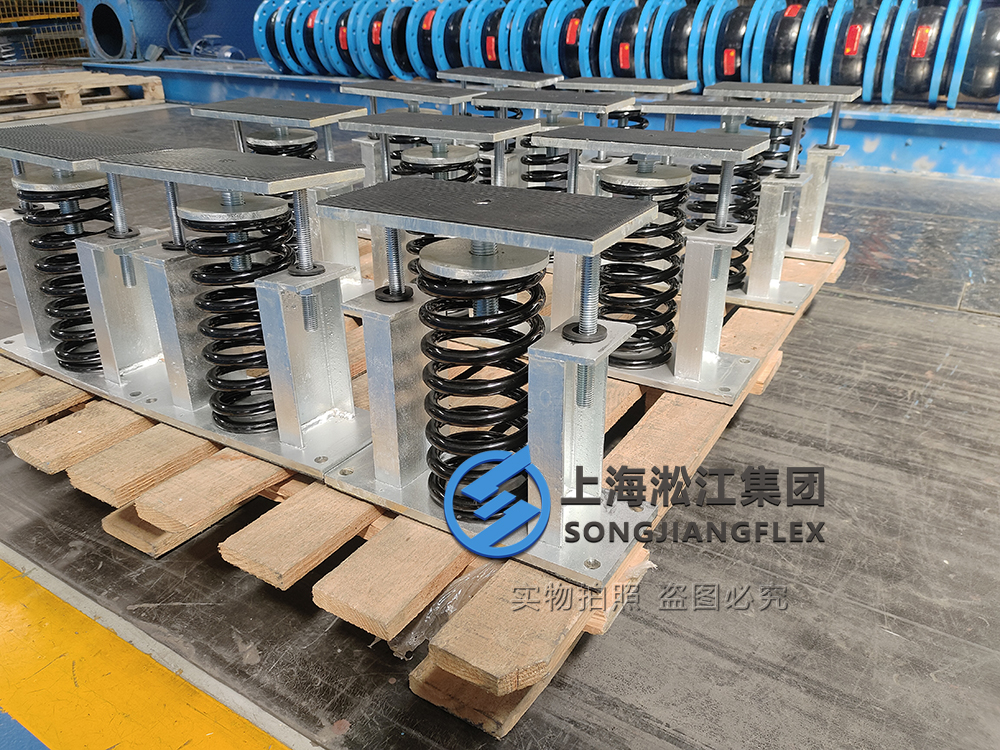

The 50mm deflection design allows the spring isolator to have more flexibility and damping capacity when dealing with different vibration frequencies. Compared to standard isolators, the 50mm deflection design provides superior isolation in most high-frequency vibrations, preventing internal components from wear caused by vibrations, ensuring long-term equipment use.

Increased Flexibility

The larger the deflection of the spring isolator, the better its ability to absorb vibrations. This is especially effective in handling high-intensity vibrations and high-frequency noise. The 50mm deflection design ensures that it maintains good flexibility even under high loads, preventing vibrations from being transmitted to other parts of the equipment.

How to Choose the Right 50mm Deflection Spring Vibration Isolator

Selecting the right spring vibration isolator requires considering the vibration characteristics and load requirements of the equipment to optimize its performance. First, understand the vibration frequency, amplitude, and load of the equipment. Next, select the appropriate deflection and materials based on the equipment’s weight and working environment. The 50mm deflection design is ideal for medium to high-frequency vibration isolation, effectively reducing mechanical wear and noise pollution.

Customization Based on Needs

Different equipment has different vibration isolation requirements. Customizing the 50mm deflection spring vibration isolator based on specific application needs can optimize the design to maximize vibration isolation effectiveness. Especially in special environments, a customized solution ensures the best performance and stable equipment operation.

Advantages of Custom 50mm Deflection Spring Vibration Isolators

Customized 50mm deflection spring vibration isolators provide tailored solutions to meet specific customer needs, adapting to various special equipment requirements. Whether it’s corrosion resistance, high-temperature tolerance, or additional load support, a customized solution can be optimized to meet specific needs, ensuring stable operation in diverse environments.

Tailored Solutions for Special Needs

Through professional design and optimization, customized isolators provide better adaptability, ensuring optimal vibration control for equipment under various working conditions. For equipment with strict vibration requirements, customized solutions are the most suitable choice.

What is the Purpose of a Spring Isolator?

Spring isolators are designed to reduce the transmission of vibrations and noise from one part of a machine to another, thereby enhancing performance and longevity. The primary function of a spring isolator is to absorb and dissipate vibrations that could cause damage to machinery or lead to noise pollution in industrial environments.

Purpose in Industry

Spring isolators serve to absorb and dissipate energy from vibrations, isolating sensitive equipment and ensuring smooth, noise-free operation. They are particularly useful in protecting machinery from vibration-related damage in high-frequency or high-load applications.

What is the Purpose of a Vibration Isolator?

A vibration isolator’s main purpose is to mitigate the effects of vibrations, which can damage machinery and disrupt operations in various industrial settings. Vibration isolators act as a barrier between vibrating sources and sensitive equipment, ensuring smooth operation and reducing the likelihood of breakdowns or performance degradation.

Reduces Equipment Wear and Tear

By absorbing and isolating vibrations, vibration isolators help maintain the structural integrity of machinery, reducing wear and tear on components and ensuring longer operational lifespans.

What is a Good Vibration Isolator?

A good vibration isolator is one that offers superior vibration dampening capabilities, ensuring durability and performance even in demanding environments. High-quality isolators should be able to effectively isolate vibrations across a wide range of frequencies while remaining durable under load and environmental stress.

Key Features of a Good Isolator

A good vibration isolator will efficiently reduce vibration transmission, be durable under varying environmental conditions, and provide long-term reliability. It should be able to adapt to different operating conditions, offering both flexibility and strength to accommodate different vibration profiles.

What is Isolator Deflection?

Isolator deflection refers to the amount of displacement an isolator undergoes under a given load, which determines its ability to absorb vibrations. The deflection level is a key factor in determining how much vibration an isolator can absorb and how effective it will be in isolating equipment from external vibrations.

Optimal Deflection for Effectiveness

The right amount of deflection ensures that the isolator can adequately absorb vibrations without allowing excessive movement, which could result in ineffective vibration isolation.

How to Reduce Vibration Transmissibility?

Reducing vibration transmissibility involves using devices like vibration isolators and ensuring proper installation to minimize vibration transfer. The key to reducing transmissibility is selecting the right isolator and placing it in the right position to absorb vibrations before they reach sensitive equipment.

Vibration Control Techniques

To reduce transmissibility, the use of well-designed isolators, proper material selection, and optimal installation practices are key factors in achieving effective vibration control. Maintenance and regular monitoring are also crucial for sustaining low transmissibility levels.

What are the Requirements for a Vibration Isolator?

The primary requirements for a vibration isolator include high durability, appropriate deflection characteristics, and resistance to environmental factors. A good isolator must be able to withstand operational loads, be resistant to wear, and provide effective vibration reduction across various frequencies and amplitudes.

Ensuring Long-Term Performance

To ensure long-term performance, a vibration isolator must be designed with materials that are suited to the operating environment. For example, isolators used in high-temperature or corrosive environments require specialized materials to ensure longevity and optimal performance.

Vibration Isolator Specification

Vibration isolator specifications are essential for selecting the right product that fits both the load and vibration requirements of the equipment. Specifications typically include details such as load capacity, deflection values, and frequency range, all of which guide the selection of the appropriate isolator.

Choosing Based on Specifications

When selecting a vibration isolator, it’s important to review its specifications to ensure it matches the needs of the application. Properly understanding these parameters helps ensure optimal performance and longevity.

Vibration Isolator Installation Instructions

Correct installation of vibration isolators is essential for achieving optimal performance and ensuring the longevity of the equipment. Installers must follow the manufacturer’s guidelines to ensure that the isolators are positioned correctly and aligned to handle the specific vibrations.

Proper Installation for Effectiveness

By adhering to the manufacturer’s installation instructions, you ensure that vibration isolators will function properly and provide maximum vibration isolation. Proper alignment and securing are key to effective isolation and preventing premature wear.

Spring Vibration Isolator Selection Guide

Selecting the right spring vibration isolator involves evaluating factors like load capacity, deflection, and the specific type of vibrations that need to be mitigated. The selection guide should consider all aspects of the equipment’s vibration profile to ensure compatibility.

Key Selection Criteria

A good spring vibration isolator selection guide should include considerations like the weight of the equipment, frequency of vibrations, and operational conditions. This ensures that the chosen isolator provides the best vibration isolation possible.

Summary

Custom 50mm deflection spring vibration isolators provide optimal vibration isolation, enhancing equipment stability and durability. They are an effective solution for vibration control across various industrial applications.