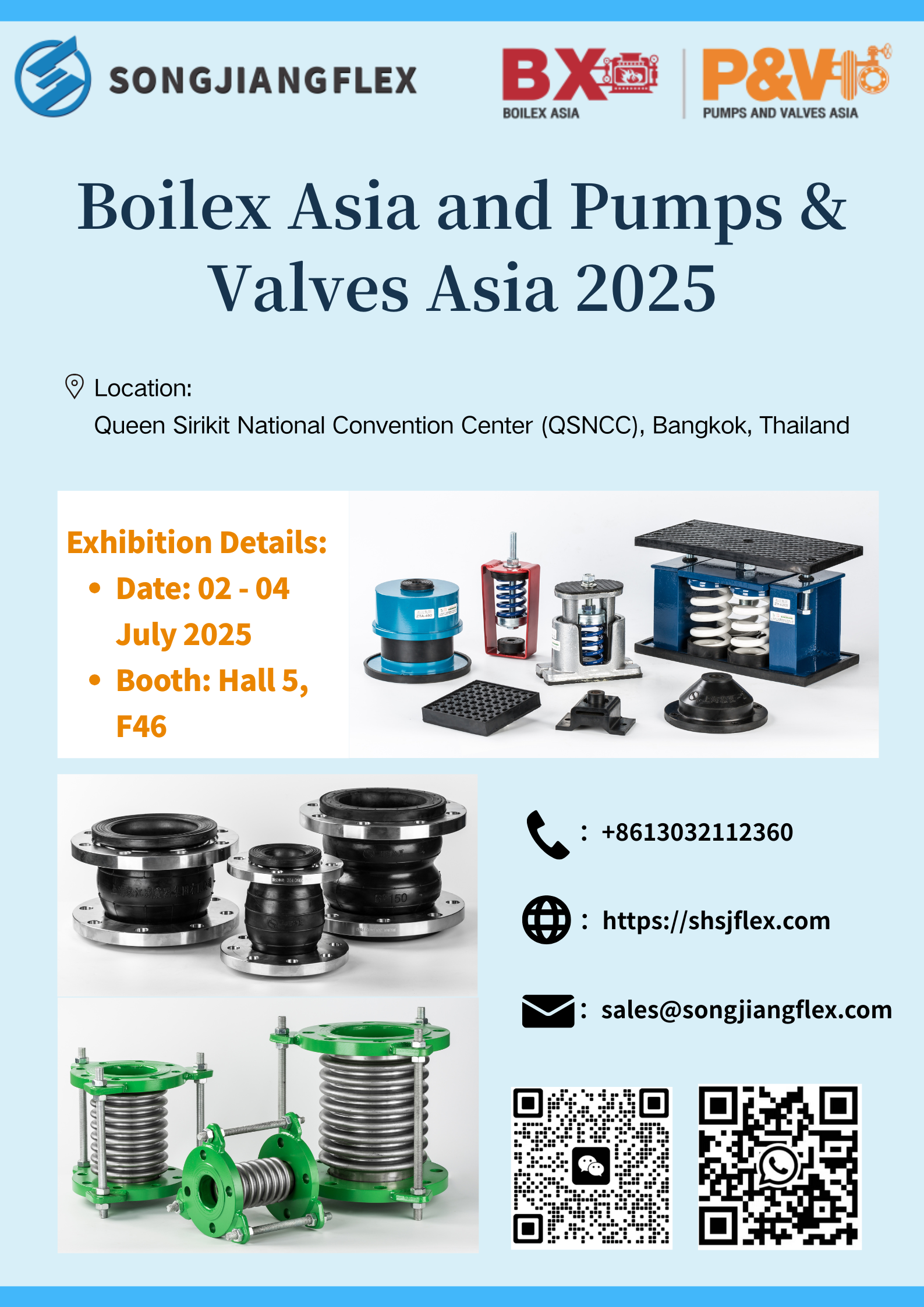

Event Date: July 2–4, 2025

Venue: Queen Sirikit National Convention Center (QSNCC), Bangkok, Thailand

Booth: Hall 5, F46

Event Introduction

Boilex Asia and Pumps & Valves Asia are leading professional exhibitions in the boiler and pump valve industry across Asia, dedicated to promoting technological advancement and product innovation. In 2025, we will showcase our core pipeline and vibration control products—including rubber expansion joints, bellows, and spring vibration isolators—at Booth F46 in Hall 5 at QSNCC, Bangkok. This article explores the product classifications and their applications in boilers, valves, and pumps, helping industry professionals better understand and select appropriate solutions.

Overview of Rubber Expansion Joints, Bellows, and Spring Vibration Isolators

1. Rubber Expansion Joints

Rubber expansion joints are flexible pipeline connectors designed to absorb thermal expansion, mechanical vibration, and equipment displacement, ensuring system safety and stability. Key types include:

-

Standard Rubber Joints: Suitable for low-pressure HVAC and water systems, usually made from natural rubber or NBR.

-

Reinforced Rubber Joints: Contain steel wire rings for medium to high pressure applications.

-

Corrosion-Resistant Rubber Joints: Made from EPDM, fluororubber, etc., for chemical and corrosive environments.

-

Flanged Rubber Joints: Easy to install and maintain, widely used in boiler and pump piping.

-

Corrugated Rubber Joints: Feature corrugations for enhanced flexibility and vibration absorption.

2. Bellows

Bellows offer excellent elasticity and compensation capabilities and are widely used in steam, gas, and fluid pipelines. Main types:

-

Metal Bellows: Typically stainless steel or alloy, capable of withstanding high temperature and pressure, used in steam boilers and high-pressure pumps.

-

Rubber Bellows: Suitable for low temperature and pressure environments, provide superior vibration absorption.

-

Composite Bellows: Combine metal and rubber materials for both strength and flexibility, adapted for complex conditions.

3. Spring Vibration Isolators

Spring vibration isolators effectively absorb mechanical vibration and shocks to protect equipment and piping. Main types include:

-

Helical Spring Isolators: Basic types broadly used across machinery.

-

Adjustable Spring Isolators: Allow preload adjustment to meet varying operational conditions.

-

Damped Spring Isolators: Include oil or air damping for enhanced energy dissipation.

-

Composite Spring Isolators: Combine springs and rubber for improved vibration and shock absorption.

Key Boiler, Valve, and Pump Types and Their Application Requirements

1. Boilers

Boilers generate steam or hot water and come in many types:

-

Coal-Fired Boilers: High temperature and pressure with corrosive media, requiring high heat and corrosion resistance.

-

Oil/Gas Boilers: Slightly lower temperature and pressure, requiring fire-resistant materials.

-

Biomass Boilers: Contain particulate media, needing abrasion-resistant joints and bellows.

-

Waste Heat Boilers: Experience rapid temperature changes, requiring high flexibility and fatigue resistance.

-

Steam Boilers: High-temperature steam working conditions mainly use metal bellows and high-temp rubber joints.

2. Valves

Valves control flow and pressure in fluid systems, with diverse types:

-

Gate Valves: Full open/close with low flow resistance; require high sealing and shock resistance.

-

Globe Valves: Used for precise flow regulation; need good vibration damping to protect seals.

-

Ball and Butterfly Valves: Fast operation with noticeable vibration; spring isolators absorb transient shocks.

-

Check and Safety Valves: Prevent backflow and overpressure, requiring specialized vibration control.

3. Pumps

Pumps vary widely, with different vibration and shock profiles:

-

Centrifugal Pumps: Used for clear and low-viscosity fluids, moderate vibration; often paired with rubber bellows.

-

Submersible Pumps: Used in water drainage and sewage, requiring corrosion and pressure resistant joints.

-

Plunger Pumps: High pressure and vibration; metal bellows and adjustable spring isolators preferred.

-

Gear and Screw Pumps: For viscous and slurry fluids, wear resistance is critical.

-

Vacuum Pumps: Low-pressure with high vibration frequency; require precise vibration isolation.

1. How to Select Suitable Rubber Expansion Joint Materials and Structures for Different Boiler Media (Steam, Water, Gas)?

Different boiler media impose distinct requirements on rubber joints. Steam involves high temperature and dry conditions, recommending materials like silicone or fluororubber with excellent aging resistance. Water media, with lower temperatures, suit EPDM or NBR materials due to water and abrasion resistance. Gas media require fire-retardant and flame-resistant rubber compounds. Structurally, steel wire reinforced rubber joints enhance pressure capacity, while corrugated designs improve flexibility and compensation. Correct material and design ensure longevity under harsh boiler conditions.

2. Comparison of Vibration Absorption Performance Between Metal Bellows and Rubber Bellows in Pump Systems

Metal bellows offer excellent high-temperature and high-pressure resistance, ideal for steam and high-pressure pumps, but have limited elasticity and vibration damping compared to rubber bellows. Rubber bellows provide superior flexibility and shock absorption, suitable for low- to medium-pressure pumps but have limitations in temperature and pressure tolerance. Optimal selection depends on pump operating parameters and media characteristics to balance durability and vibration control.

3. How Do Spring Vibration Isolators Adjust Stiffness to Effectively Buffer Valve Water Hammer Shocks?

Valve opening and closing generate water hammer shocks causing pipe and equipment impact. Adjustable spring isolators vary preload to match the impact force, achieving optimal stiffness for maximum shock absorption. Properly tuned isolators reduce pipe vibration and noise, and protect components from fatigue damage. Incorrect stiffness settings can worsen vibrations, so on-site adjustments are crucial for safe operation.

4. How to Ensure Corrosion and Heat Resistance of Rubber Expansion Joints in High-Temperature, High-Pressure Coal-Fired Boilers?

Coal-fired boiler media contain sulfur compounds and acidic gases that cause corrosion. Rubber joints use high-corrosion resistant materials like fluororubber and neoprene, often combined with PTFE liners to shield the rubber. Steel wire reinforcements provide structural strength under high temperature and pressure. Quality control and routine maintenance are essential to guarantee long service life in harsh conditions.

5. Influence of Pump Vibration Characteristics on Bellows Design

Pump types differ in vibration amplitude and frequency, affecting bellows design parameters like elasticity, wall thickness, and number of convolutions. Centrifugal pumps produce moderate vibration suited to rubber bellows with good elasticity. High-pressure plunger pumps require thick-walled, multiple-convolution metal bellows for fatigue resistance. Material selection also depends on media abrasiveness and corrosiveness to ensure durability and vibration mitigation.

6. Contributions of Spring Vibration Isolators in Valve Systems to Reduce Mechanical Vibration and Extend Equipment Life

Valve actuation causes mechanical shocks and vibration that can loosen piping, damage seals, or cause fractures without effective damping. Spring isolators absorb these shocks and attenuate vibration transmission to connected structures. Long-term use reduces failure rates, lowers maintenance frequency, and enhances system reliability and lifespan.

7. Case Study: Application of Adjustable Spring Vibration Isolators in Automated Pump Stations

A municipal automated pump station adopted adjustable spring isolators to dynamically tune vibration isolation based on load conditions. This reduced equipment vibration amplitude by 40%, extended maintenance intervals by 30%, and improved operational stability. The case highlights the isolators’ flexibility and energy-saving benefits, offering a reliable vibration control solution for modern automated facilities.

8. Advantages and Precautions of Combined Use of Rubber Expansion Joints and Metal Bellows in Boiler and Pump Systems

Combining metal bellows and rubber joints leverages both materials’ strengths: metal bellows handle high temperature and pressure, while rubber joints provide excellent flexibility and vibration absorption. Design must consider differences in thermal expansion coefficients and ensure proper sealing at joints to prevent stress concentrations and leakage. Meticulous design and maintenance ensure system reliability and safety.

Conclusion

At Boilex Asia and Pumps & Valves Asia 2025, we warmly welcome industry experts and customers to visit us at Hall 5, Booth F46 in QSNCC Bangkok to explore the latest technologies and solutions in rubber expansion joints, bellows, and spring vibration isolators across boiler, valve, and pump applications. Let us work together to shape a safer, more efficient future for the industry.