Earthquakes cause severe equipment damage and downtime. Without proper protection, machinery is vulnerable. Seismic spring vibration isolators offer a reliable solution to stabilize and safeguard your equipment.

Seismic spring vibration isolators absorb and restrain lateral seismic forces, preventing damage to critical machinery like HVAC systems, pumps, and generators. Designed for high durability and compliance with building codes, they provide essential vibration control and structural stability, especially in earthquake-prone areas.

Let’s explore the key questions about seismic spring vibration isolators and why they matter for your equipment’s safety.

1. What is a seismic spring vibration isolator and how does it work?

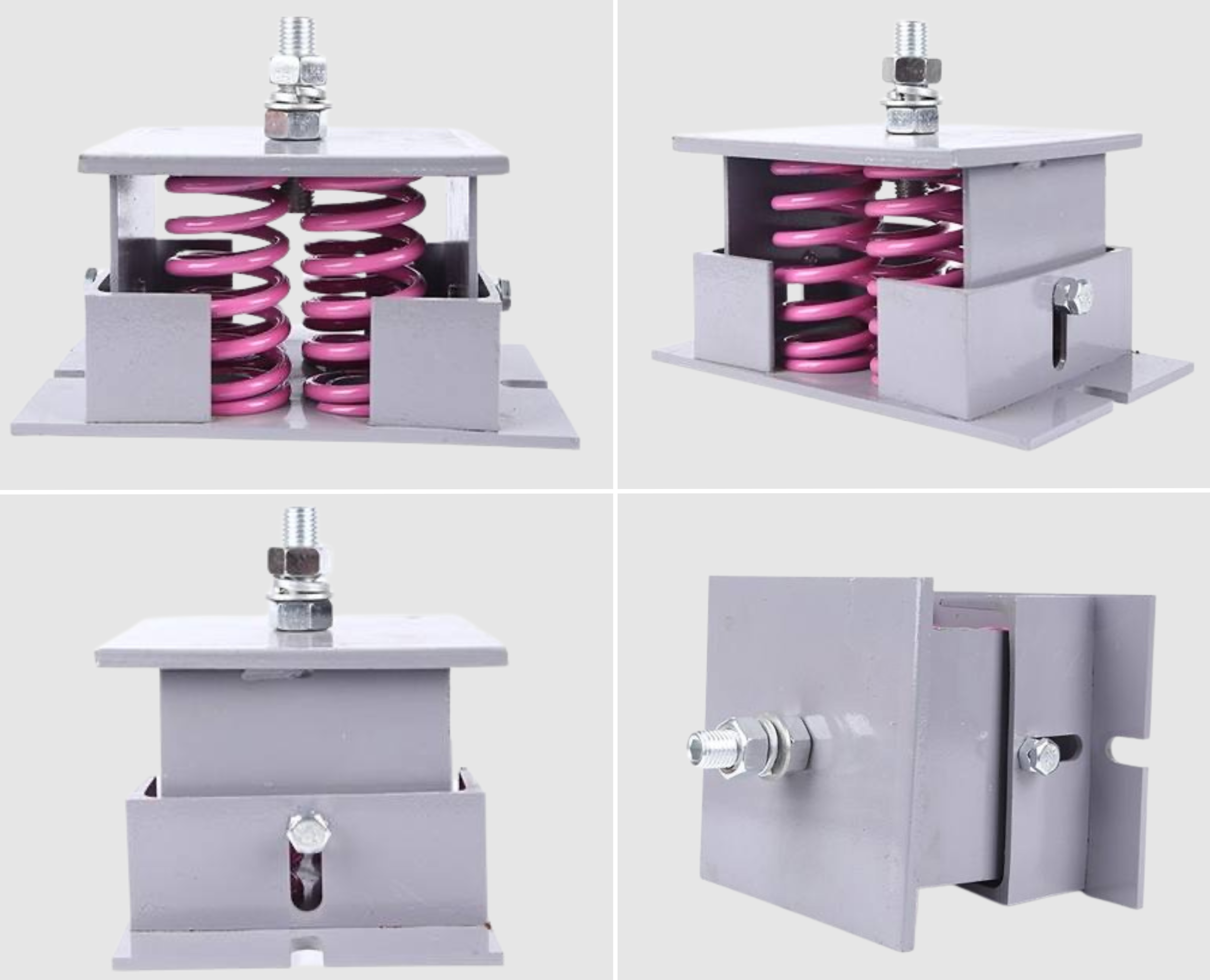

A seismic spring vibration isolator is a specialized device designed to absorb vibrations caused by earthquakes. It stabilizes equipment by restricting lateral and vertical movements.

Seismic spring isolators combine springs and restraining components to dampen seismic shocks, protecting machinery from displacement and structural damage during earthquakes.

These isolators function by allowing controlled movement under normal operation but limit excessive displacement during seismic events. They reduce stress on piping and equipment, ensuring continuous operation and minimizing repair costs. The design integrates mechanical springs with restraints tailored to seismic forces.

2. What is the difference between a standard spring isolator and a seismic spring isolator?

Standard spring isolators primarily reduce operational vibrations. Seismic isolators add lateral restraints to handle earthquake forces effectively.

While standard isolators focus on vertical vibration control, seismic spring isolators provide additional lateral support to prevent equipment from shifting during seismic events.

The main difference lies in seismic spring isolators’ ability to withstand horizontal loads and provide structural stability. This distinction makes them indispensable in earthquake-prone regions, where normal isolators could fail under lateral forces.

3. When should I use a seismic vibration isolator instead of a regular one?

Use seismic vibration isolators when installing equipment in areas prone to earthquakes or where building codes mandate seismic protection.

Seismic isolators are recommended for critical infrastructure or machinery exposed to seismic risk, ensuring equipment safety during unexpected tremors.

Industries like power generation, HVAC, and water supply, especially in seismic zones, benefit from seismic isolators. They are essential for equipment whose failure could lead to costly downtime or safety hazards.

4. Are seismic spring vibration isolators required by building codes?

Many building codes and standards require seismic vibration isolators for certain types of equipment in seismic zones.

Regulations such as ASCE 7 and local codes often mandate seismic protection measures, including the use of seismic spring isolators for HVAC, pumps, and generators.

Compliance ensures legal safety standards and helps avoid penalties. It also guarantees that equipment installation meets seismic performance requirements to protect assets and personnel.

5. What equipment typically requires seismic vibration isolation?

Equipment such as HVAC units, water pumps, generators, and compressors commonly need seismic vibration isolation.

Seismic isolators protect heavy, vibration-sensitive machinery critical for operations in commercial and residential buildings.

Spring vibration isolators HVAC, spring isolator for pump, and free standing spring isolator are typical applications. Ensuring these systems have seismic protection maintains operational reliability and reduces maintenance costs.

6. How much lateral movement can seismic spring isolators restrain?

Seismic spring isolators are engineered to limit lateral displacement typically within a few millimeters to several centimeters.

The lateral movement restraint depends on the isolator design, often ranging from 5 mm to 50 mm, sufficient to prevent equipment damage during seismic events.

Restrained spring isolators use mechanical stops or guides to limit horizontal movement, balancing flexibility and protection. This ensures equipment remains secure without sacrificing vibration isolation effectiveness.

7. What deflection ranges are available for seismic spring vibration isolators?

Seismic spring isolators come in various deflection ranges to suit different equipment weights and vibration characteristics.

Deflection ranges typically vary from 10 mm to 100 mm, allowing customization based on load requirements and vibration frequencies.

Selecting the proper deflection range is critical to achieve optimal isolation and seismic resistance. Songjiangflex offers a wide range of models to fit diverse applications, including floor mount vibration isolator spring types.

8. Can seismic spring isolators be used outdoors or in corrosive environments?

Yes, seismic spring isolators can be designed with corrosion-resistant materials for outdoor and harsh environments.

Using stainless steel and protective coatings, isolators withstand weather, humidity, and chemical exposure while maintaining performance.

Custom options enable deployment in coastal or industrial sites where corrosive agents are present. Regular maintenance and inspection complement these protective measures to ensure longevity.

9. How do I select the correct seismic spring isolator for my equipment?

Selecting the right isolator involves evaluating load, vibration frequency, installation location, and seismic risk.

Consulting with experts ensures the chosen isolator matches equipment weight, vibration profile, and complies with local seismic codes.

Factors like spring stiffness, deflection range, and lateral restraint capacity affect performance. Songjiangflex provides tailored solutions for spring vibration isolators HVAC systems, pumps, and fans.

10. Can seismic vibration isolators be customized for special load requirements?

Seismic vibration isolators can be customized to meet unique load and environmental demands.

Manufacturers like Songjiangflex offer design flexibility, adjusting materials, sizes, and restraint mechanisms for special applications.

Custom solutions ensure optimal vibration control and seismic protection for non-standard equipment. This supports industries with specialized machinery requiring precise isolation parameters.

Summary

Seismic spring vibration isolators provide essential protection against earthquake damage, ensuring equipment stability and operational safety.