Industrial pipelines often suffer from thermal expansion, vibration, and corrosion. Standard joints may fail under complex conditions. Customized wound and curved rubber expansion joints solve these problems efficiently.

Snippets Paragraph:

Customized wound and curved rubber expansion joints offer high-temperature and corrosion resistance, adapt to complex piping systems, reduce vibration and noise, and extend pipeline service life in industries like water treatment, chemical, and power.

Transition Paragraph:

Explore types, materials, and manufacturing processes of customized rubber expansion joints to find the optimal solution.

1. What Are Wound and Curved Rubber Expansion Joints?

Leading Paragraph:

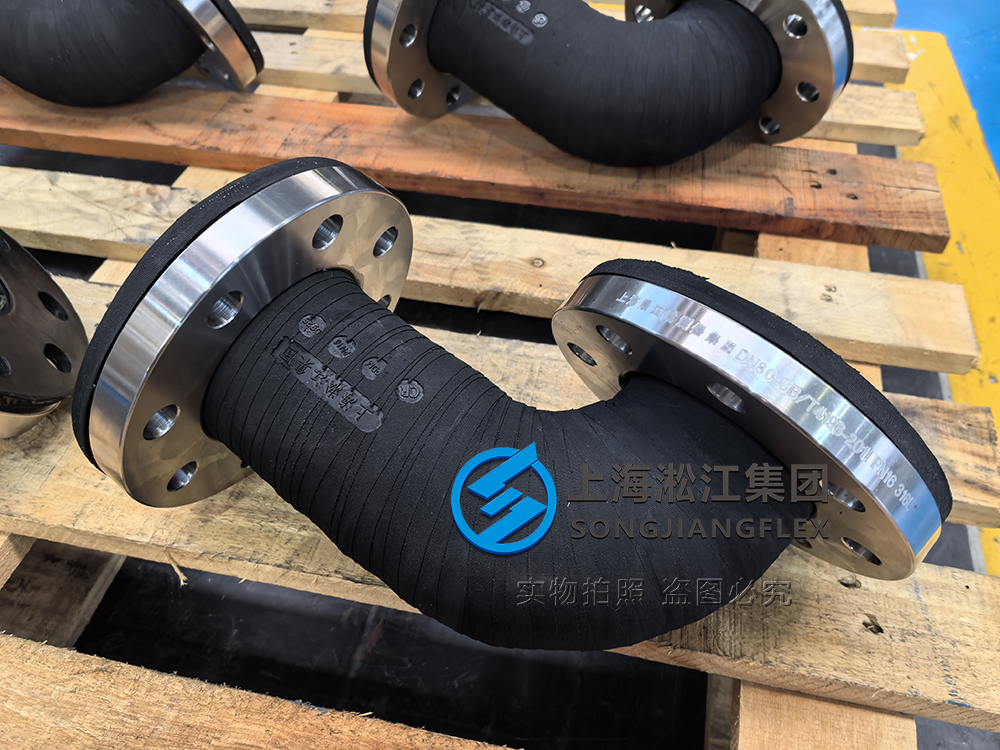

Wound and curved rubber expansion joints are flexible connectors designed to absorb axial, lateral, and angular movements in pipelines. They consist of multiple layers of reinforced rubber and sometimes a fabric or metal insert.

Snippets Paragraph:

These joints protect pipelines from thermal expansion, vibration, and misalignment. They are widely used in water pumps, fans, chemical pipes, and HVAC systems for enhanced safety and durability.

Related Content:

Curved joints allow pipelines to navigate bends without additional fittings. Wound joints provide extra strength and flexibility, making them ideal for industrial pipelines with irregular layouts. They help prevent leaks and reduce maintenance costs over time.

Additional Question: Why do pipelines require curved joints?

2. Why Choose Customized Expansion Joints Instead of Standard Ones?

Leading Paragraph:

Standard expansion joints may not fit unique pipeline configurations or extreme operating conditions. Customized joints can be designed to specific angles, diameters, and pressure ratings.

Snippets Paragraph:

Custom joints improve lifespan, performance, and safety. They adapt to non-standard installations, ensuring reliable sealing and vibration absorption.

Related Content:

For pipelines with unusual bends, high pressures, or corrosive media, customized joints prevent failures and reduce downtime. Manufacturers like Songjiangflex offer tailored solutions for such specialized requirements.

Additional Question: What special conditions can customized joints address?

3. How to Select the Right Rubber Material for Your Expansion Joint?

Leading Paragraph:

Material selection is critical for expansion joints. Common materials include EPDM, NBR, and Neoprene, each offering different temperature, chemical, and mechanical resistance.

Snippets Paragraph:

Choosing the right rubber depends on operating temperature, fluid type, and environmental conditions. Proper selection enhances longevity and reduces maintenance.

Related Content:

EPDM suits water and steam; NBR is resistant to oils and fuels; Neoprene offers moderate chemical resistance. Evaluating expected stress, temperature, and chemical exposure is essential to select the most suitable material.

Additional Question: How do different materials compare in lifespan and maintenance costs?

4. What Is the Manufacturing Process of Wound and Curved Rubber Expansion Joints?

Leading Paragraph:

Production involves rubber compounding, layer winding, forming, and vulcanization. Quality control ensures consistent thickness and performance.

Snippets Paragraph:

Automated processes and precise controls guarantee reliable sealing, uniform wall thickness, and long service life.

Related Content:

Modern factories use CNC feeding, automatic vulcanization, and testing machines to maintain high precision. Each joint is tested for pressure resistance, burst strength, and fatigue performance to meet industrial standards.

Additional Question: How is sealing ensured during the production process?

5. How Long Do Customized Rubber Expansion Joints Last?

Leading Paragraph:

Service life depends on pressure, temperature, rubber material, and maintenance practices. Correct installation is also vital.

Snippets Paragraph:

With proper selection and maintenance, these joints can last 5–15 years, even in demanding industrial environments.

Related Content:

Regular inspections for wear, cracking, or deformation help prevent failures. Avoiding extreme temperatures and corrosive exposure further extends joint lifespan.

Additional Question: Will high temperature or corrosive environments shorten lifespan?

6. Can Customized Rubber Expansion Joints Reduce Vibration and Noise?

Leading Paragraph:

Rubber’s elasticity absorbs vibration and reduces noise in pipelines, protecting connected equipment.

Snippets Paragraph:

Used in HVAC systems, water pumps, and fans, these joints improve operational stability and minimize mechanical stress.

Related Content:

By isolating vibration, the joints prevent structural damage and reduce maintenance needs. Selecting the right design enhances both noise reduction and mechanical performance.

Additional Question: How to choose the design with the best vibration reduction?

7. What Are the Common Standards and Certifications for Rubber Expansion Joints?

Leading Paragraph:

Quality certifications like ISO9001 and OHSAS 18001 ensure reliable performance and compliance with international standards.

Snippets Paragraph:

Certified joints provide assurance for export, industrial use, and critical applications, meeting customer and regulatory requirements.

Related Content:

Different markets require specific certifications. For example, power plants may demand safety compliance, while chemical plants require corrosion resistance verification. Choosing certified products ensures safety and reliability.

Additional Question: What certification differences exist across markets?

Summary:

Customized wound and curved rubber expansion joints provide reliable, durable solutions, reduce vibration and noise, and suit complex industrial applications.