Rubber expansion joints play a critical role in pipeline systems by absorbing vibration, compensating for movement, and reducing stress on connected equipment. However, selecting the wrong type of rubber expansion joint can lead to leakage, premature failure, and increased maintenance costs. Understanding the differences between various rubber expansion joint types is essential for reliable and long-term system operation.

In general, rubber expansion joints differ in structural design, connection method, rubber material, and pressure rating. Single or double sphere designs determine flexibility, rubber compounds affect media compatibility, and pressure classes define safety limits. Choosing the right combination depends on the actual working conditions of the system.

Below is a detailed explanation of the main differences between common types of rubber expansion joints.

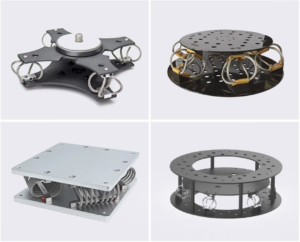

Difference Between Single Sphere and Double Sphere Rubber Expansion Joints

Single sphere and double sphere rubber expansion joints are widely used in industrial and HVAC systems. Their structural differences directly influence vibration isolation and movement compensation capabilities.

Single sphere rubber expansion joints feature a compact design and require less installation space. They are suitable for applications with moderate movement and limited space. Double sphere rubber expansion joints, with an additional arch, provide greater axial, lateral, and angular flexibility, making them more effective in absorbing vibration and reducing stress on pipelines and equipment.

For pump systems, chillers, and pipelines with noticeable vibration, double sphere rubber expansion joints are often the preferred solution.

Flanged Rubber Expansion Joints vs. Threaded Rubber Joints

The connection type of a rubber expansion joint significantly affects sealing performance and pressure resistance.

Flanged rubber expansion joints are commonly used in industrial pipelines, offering strong sealing reliability and higher pressure capacity. They are ideal for pumps, HVAC systems, and process pipelines. Threaded rubber joints, on the other hand, are typically used in small-diameter, low-pressure piping systems where easy installation is required.

Selecting the appropriate connection method helps prevent leakage and ensures long-term operational safety.

Differences Between EPDM, NBR, and Neoprene Rubber Materials

Rubber material selection directly impacts the durability and compatibility of rubber expansion joints.

EPDM rubber expansion joints are widely used in water supply and HVAC applications due to their excellent resistance to heat, ozone, and aging. NBR rubber expansion joints are suitable for oil, fuel, and petroleum-based media. Neoprene rubber offers balanced mechanical strength and moderate chemical resistance, making it suitable for general industrial environments.

Choosing the correct rubber material is essential to prevent premature degradation caused by incompatible media.

Low-Pressure, High-Pressure, and Vacuum Rubber Expansion Joints

Different pressure conditions require different structural designs.

High-pressure rubber expansion joints are reinforced with multiple fabric layers and stronger flanges to withstand internal pressure. Vacuum rubber expansion joints are designed with anti-collapse features to maintain stability under negative pressure. Using an incorrectly rated rubber expansion joint may result in deformation or system failure.

Selecting Rubber Expansion Joints for Different Applications

In pump systems, rubber expansion joints reduce vibration and protect equipment connections. HVAC systems benefit from flexible joints that absorb thermal expansion and reduce noise. In chemical and industrial pipelines, material compatibility and pressure rating are critical selection factors.

Application-based selection ensures optimal performance and extended service life.

Rubber Expansion Joints vs. Metal Expansion Joints

Rubber expansion joints and metal expansion joints are both used for movement compensation but perform differently.

Rubber expansion joints excel in vibration and noise reduction, making them ideal for rotating equipment. Metal expansion joints are better suited for high-temperature and high-pressure conditions but transmit vibration more easily.

Typical Service Life of Rubber Expansion Joints

Under proper operating conditions, rubber expansion joints typically last between 5 and 10 years. Factors such as temperature, pressure, media type, and installation quality all influence service life.

Correct selection and proper installation significantly extend the lifespan of rubber expansion joints.

Do Rubber Expansion Joints Require Control Rods?

Control rods are recommended for high-pressure or large-diameter rubber expansion joints to limit excessive axial movement. They enhance system safety and prevent overextension caused by internal pressure thrust.

Conclusion

Understanding the differences between various types of rubber expansion joints helps ensure safe operation, improved system reliability, and reduced long-term maintenance costs.