In modern industrial production, vibration is an inevitable challenge. From heavy machinery to pipeline systems, vibrations can cause equipment wear, noise, and even safety risks. Choosing the right vibration isolator is essential to ensure stable operation. Today, industrial vibration isolators come in a wide variety, meeting diverse application needs and helping businesses protect equipment, reduce noise, and improve productivity.

Main Types of Vibration Isolators

-

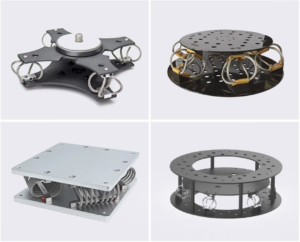

Spring Isolators: Ideal for heavy equipment such as compressors, generators, and chillers, offering excellent vibration isolation under high loads.

-

Rubber Isolators: Suitable for medium and small machines and piping systems, easy to install, corrosion-resistant, and low-maintenance.

-

Wire Rope Isolators: Resistant to high temperatures and pressures, perfect for steam pipelines or industrial furnaces.

-

Air Spring Isolators: Adjustable in height and stiffness, designed for high-precision or large equipment requiring precise vibration control.

-

Vibration Pads: Commonly used under small equipment or machinery to reduce vibration transmission to the floor and environment.

-

Rubber Expansion Joints: Absorb thermal expansion and vibration in pipelines while reducing noise.

-

Bellows Compensators: Flexible pipe connectors that absorb movement and vibration to prevent damage.

-

Braided Hoses: Flexible, corrosion-resistant, fatigue-resistant hoses suitable for high-pressure or hot water systems.

-

Rubber Joints: Ideal for pipeline vibration damping and sealing, widely used in municipal, chemical, and power industries.

Application Scenarios

-

Industrial Machinery: Compressors, fans, pumps, injection molding machines, etc.

-

Piping Systems: Hot water, steam, chemical liquid pipelines, and drainage systems.

-

Construction & HVAC: Air conditioning units, fan coil units, and duct systems.

-

Precision Equipment: Laboratory instruments and testing machines requiring high stability.

Key Considerations for Choosing Vibration Isolators

-

Load Capacity: Ensure the isolator can handle the equipment weight and vibration amplitude.

-

Vibration Frequency: Select spring, rubber, or air spring isolators according to operational frequency.

-

Environmental Conditions: High or low temperatures, chemical exposure, or moisture require durable materials.

-

Installation Method: Floor-mounted, suspended, or pipeline-connected installations require compatible isolator designs.

-

Maintenance Needs: High-quality products reduce maintenance and replacement costs.

Advantages of Full-Range Vibration Isolators

-

Extend Equipment Life: Reduce wear, tear, and potential failures.

-

Reduce Noise Pollution: Effective vibration absorption improves working environments.

-

Increase Productivity: Smooth equipment operation reduces downtime and maintenance.

-

Meet Diverse Needs: Suitable for pipelines, heavy machinery, and precision instruments alike.

Related Insights

With industrial demands becoming more diverse, companies require a full range of vibration isolators, from simple rubber pads to precision air springs. Partnering with a supplier offering complete solutions ensures safer, more reliable, and efficient operations.