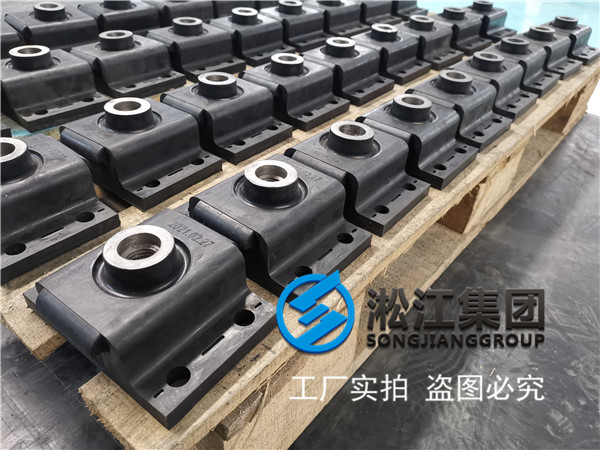

Urgent orders often delay projects. Songjiangflex provides high-quality, custom rubber vibration isolators with fast production and delivery, solving clients’ timing and performance concerns.

From design confirmation to shipping, Songjiangflex manages the full production process for rubber vibration isolator pads. Automated lines, strict quality checks, and reliable logistics guarantee timely delivery to international clients, including bulk orders for Iran, ensuring customer satisfaction and consistent product performance.

Discover how we handle custom orders, maintain product quality, and optimize vibration isolation solutions for our global clients.

How Does Songjiangflex Handle Custom Rubber Vibration Isolator Orders?

Custom orders begin with understanding client requirements. Our team communicates closely to design rubber vibration isolator mounts that meet specific application needs.

Each order is reviewed for size, material, and load capacity. Using advanced CNC and automated rubber forming machines, Songjiangflex ensures every heavy duty vibration isolator meets design specifications and performance expectations.

The process includes initial consultation, CAD design approval, material selection, and prototype testing. For Iranian clients, we customized rubber isolator bushings and rubber isolator feet to handle unique operational loads, ensuring durability and optimal vibration dampening.

What Measures Ensure Timely Delivery to International Clients?

On-time delivery is critical, especially for urgent overseas orders. Songjiangflex integrates production scheduling with efficient logistics.

Automated production lines reduce lead times, while a dedicated shipping team coordinates customs and freight. Heavy duty anti vibration rubber mounts are carefully packaged to prevent damage, ensuring Iranian clients receive their orders on schedule.

We maintain real-time inventory and production tracking systems. For bulk orders, such as heavy duty vibration isolators, we optimize shipment batches and partner with trusted carriers, addressing common client pain points like delayed peak-season deliveries.

How Does Songjiangflex Maintain Product Quality for Bulk Orders?

Quality control ensures every rubber isolator mount functions reliably. Bulk orders require rigorous testing and standardized procedures.

Our Nantong testing center inspects rubber vibration isolator pads for hardness, durability, and load capacity. Each unit undergoes hydrostatic, fatigue, and vibration testing to meet international standards.

Using advanced equipment such as universal tensile machines and high-temperature testing machines, we verify every batch of rubber isolator bushings and vibration isolator hangers. Consistent quality ensures clients in Iran and other countries can trust our products.

Why Do Customers Choose Songjiangflex for Vibration Isolators?

Clients choose us for expertise, customization capabilities, and a reliable overseas delivery record.

Songjiangflex offers rubber isolator mounts home depot quality with industrial and commercial customization. Years of experience in global markets build confidence in product durability and performance.

From water pumps and fans to generators and compressors, our rubber isolator feet and mounts provide essential vibration isolation. Iranian clients value our ability to meet urgent specifications while maintaining high quality, making us a preferred supplier for repeat orders.

Is Rubber a Good Vibration Dampener?

Rubber is highly effective at absorbing vibration due to its elasticity and resilience, making it ideal for isolators and mounts.

Rubber vibration isolator pads and mounts efficiently dampen both high- and low-frequency vibrations, protecting machinery and reducing noise in industrial and commercial applications.

Rubber isolator bushings and heavy duty anti vibration rubber mounts provide durable solutions. Its natural flexibility allows precise adaptation to different load conditions, ensuring equipment longevity and operational safety.

What Are Rubber Isolators Used For?

Rubber isolators are versatile, serving multiple industries and equipment types to control unwanted vibrations.

Applications include HVAC units, diesel generators, stamping machines, and transformers. Rubber vibration isolator mounts reduce noise, prevent mechanical wear, and enhance system stability.

Clients in Iran use rubber isolator feet and rubber isolator bushings for custom machinery setups. The adaptability of these isolators allows them to fit complex designs while maintaining optimal vibration dampening, proving their value across multiple industrial sectors.

What Is the Best Material to Reduce Vibration?

Selecting the right material is key to effective vibration control. Rubber is among the most reliable choices.

Heavy duty vibration isolators, rubber isolator mounts, and rubber vibration isolator pads outperform many alternatives due to elasticity, durability, and chemical resistance, making them ideal for diverse machinery.

While metal springs and composites have niche applications, rubber isolator feet and bushings provide consistent performance under variable loads, temperature, and environmental conditions, especially in industrial and construction applications.

Do Anti-Vibration Pads Really Work?

Anti-vibration pads are effective if properly matched to the equipment and vibration frequency.

Heavy duty anti vibration rubber mounts and rubber isolator feet absorb energy, reduce noise, and protect equipment, confirming their practical utility in industrial settings.

Clients benefit from customized pads paired with rubber isolator bushings and mounts to maximize vibration control. Improper sizing or placement can reduce effectiveness, so our team ensures every solution is tailored for the client’s machinery.

Who Shouldn’t Use a Vibration Plate?

Certain equipment types or sensitive environments are not suited for vibration plates.

High-precision machinery or setups with delicate instrumentation may be damaged. Using rubber isolator mounts or vibration isolator hangers is often safer and more effective.

Our consultants guide clients in Iran to choose appropriate isolation methods, emphasizing rubber vibration isolator pads and mounts for delicate equipment to prevent operational failures or measurement inaccuracies.

How to Dampen High Frequency Vibration?

High-frequency vibrations require specialized damping solutions.

Heavy duty vibration isolators, rubber vibration isolator pads, and rubber isolator bushings can be designed to absorb high-frequency energy, protecting equipment and reducing noise.

By adjusting material hardness and isolator geometry, Songjiangflex engineers optimize damping. Using rubber isolator feet and mounts ensures both low- and high-frequency vibrations are controlled, providing reliable performance across various industrial applications.

Summary

Songjiangflex delivers customized, high-quality rubber vibration isolators with fast production and reliable international shipping, ensuring client satisfaction and optimal vibration control for diverse industrial applications.