In industrial and building systems, vibration from mechanical equipment can significantly affect operational stability, structural integrity, and workplace comfort. Common vibration sources include pumps, engine sets, fans, air conditioners, machine tools, vibrating screens, compressors, and die-cutting machines. The JD Type Rubber Vibration Isolator provides a reliable solution for controlling vibration across a wide range of equipment.

Why Should You Pay Attention to Equipment Vibration?

During operation, mechanical systems generate vibration due to imbalance, friction, and air pulsation. If left unmanaged, such vibration can lead to:

-

Excessive noise

-

Structural fatigue and equipment damage

-

Component misalignment or failure

-

Decreased precision in sensitive equipment

-

Poor working conditions for operators

That’s why terms like compressor vibration isolator, fan vibration isolator, and die-cutting machine vibration isolation solution are commonly searched by industrial users.

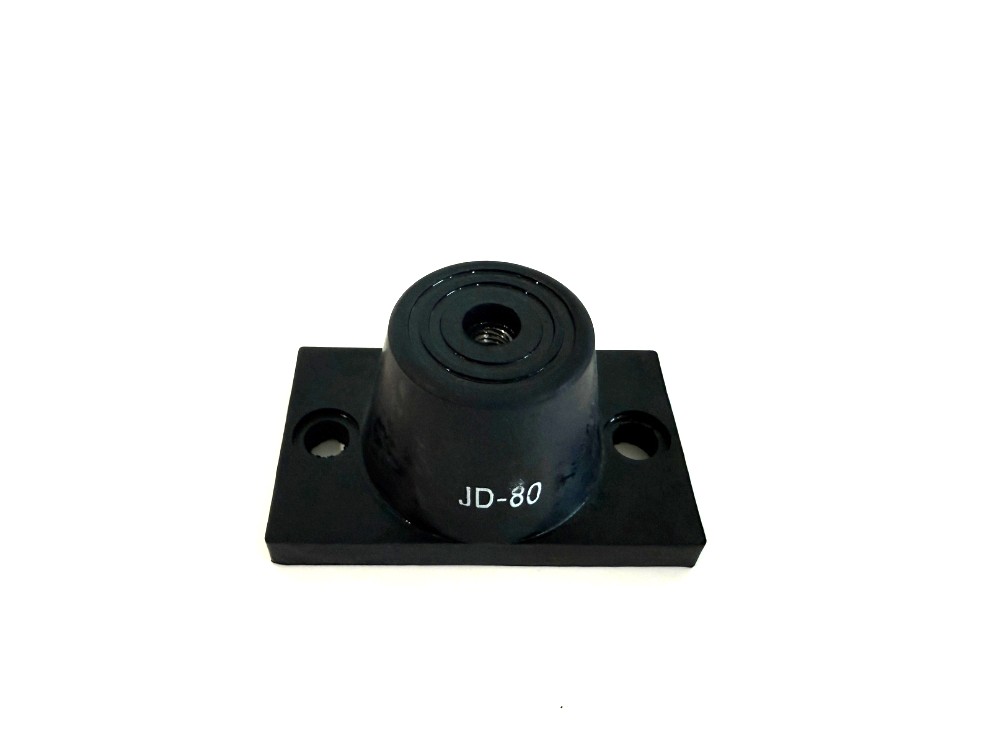

JD Type Rubber Vibration Isolator – Product Overview

The JD Type Rubber Vibration Isolator is a high-performance isolator made of carbon steel and natural rubber. It features:

-

Metal parts covered with rubber for corrosion resistance

-

Low natural frequency and optimal damping ratio

-

High lateral stiffness and low dynamic coefficient

-

Compact design and stable vibration isolation performance

-

Easy installation and wide compatibility with mechanical systems

This product is ideal for use in fans, pumps, engine sets, compressors, and die-cutting machines, offering effective shock and vibration reduction.

Equipment Applications of JD Rubber Vibration Isolator

Here’s how the JD isolator performs across various common equipment:

1. Fan Vibration Isolator

Fans, especially those installed on rooftops or ducts, generate low-frequency vibration. The JD isolator helps minimize transmission to building structures, reducing noise and enhancing comfort.

2. Compressor Vibration Isolator

Compressors are known for strong vibrations that can damage piping systems. The JD isolator significantly improves operational stability, making it an excellent compressor vibration solution.

3. Die-Cutting Machine Vibration Solution

Die-cutting machines generate frequent impact vibrations during high-speed stamping. The JD isolator effectively absorbs shock energy, making it a reliable vibration isolation solution.

4. Pumps and Water Treatment Systems

Pumps often transfer vibration to surrounding pipelines and structures. JD rubber isolators prevent resonance and water hammer effects, ensuring safe operation.

5. Engine Sets and Power Equipment

Engine sets are major sources of low-frequency vibration. JD isolators enhance system stability, reduce structural transmission, and improve operator comfort.

6. Air Conditioners and HVAC Units

Compressor and fan vibrations from HVAC systems can be transmitted through floors and walls. JD isolators reduce structure-borne noise, enhancing indoor comfort.

7. Machine Tools and Vibrating Screens

Machine tools require precision and stability, while vibrating screens must manage controlled vibration. JD isolators work effectively in both scenarios, limiting unnecessary transmission.

Conclusion

Whether used in pumps, fans, compressors, or die-cutting machines, vibration control is critical for equipment reliability and workplace safety. The JD Type Rubber Vibration Isolator offers a compact, corrosion-resistant, and high-performance solution. Its exceptional isolation performance makes it ideal for applications requiring compressor vibration isolation, fan isolation, or die-cutting vibration control.

If you’re facing vibration challenges in your equipment, consider the JD rubber isolator for a stable, efficient, and long-lasting solution.