Rubber Expansion Joints

High-Quality, Customizable Rubber Expansion Joints with Standard Compliance and Flexible Solutions

Molded single-sphere rubber bellows are designed for the most demanding piping systems, allowing for axial, lateral, and angular movements with easy installation. which directional movement, reducing vibration and noise, and offering various flange materials for flexibility.

Molded double-sphere rubber expansion joints are engineered to handle the most demanding piping system setups.Their robust design ensures durability in complex conditions. BodyMaterial:NR,NBR,EPDM,FKM,VITON, BUTYL(IIR), HYPALON,CR(chloroprene)

Molded wide arch expansion joints feature the lowest spring rates on the market and require minimal force for deflection.Building length: 255 – 550mm BodyMaterial:NR,NBR,EPDM,CR(chloroprene) Flange material:zinc plated carbon steel EN1092 PN6/10 – ASME B16.5 150lbs.

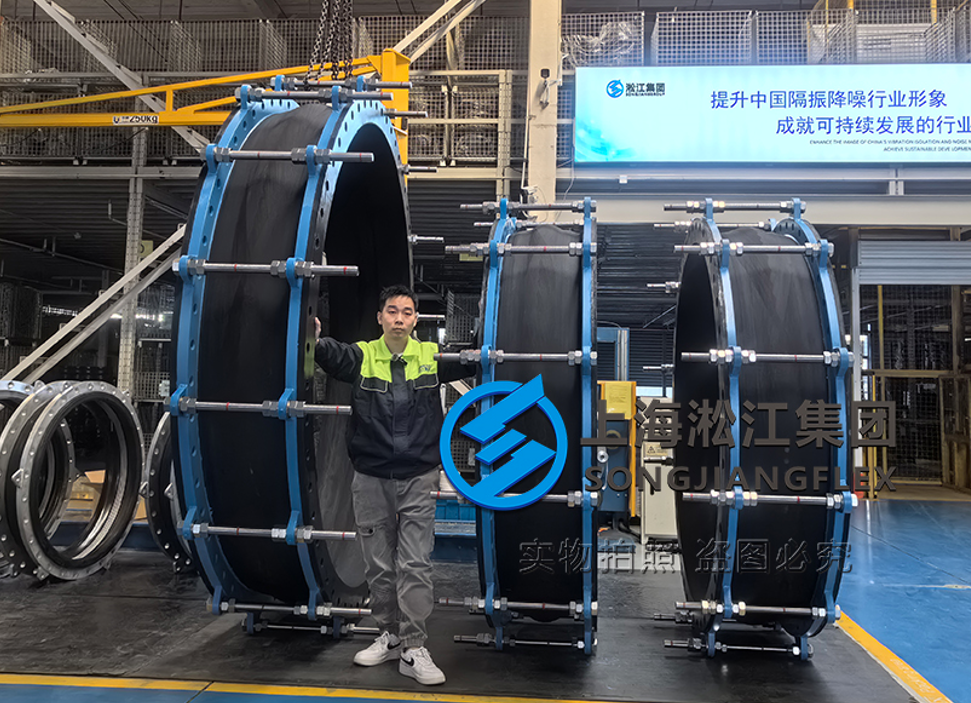

KHD Handmade joint Integrated steel flanges and built to withstand even the most rigorous piping system configurations.The pressure can reach 40 bar, and the temperature can reach 190℃.Gives small reaction forces, providing high reliability and long service life.Customizable in any size.

Rubber compensators are elastic connectors with turnable SAE aluminum alloy flanges and a high-quality nitrile bellow. They are suitable for mineral oil products, crude oil, lubrication oil, cooling oil, water, and fuel with up to 30% aromatic content, making them ideal for suction and return lines.

The Songjiang expansion joints have flanges that comply with ANSI/ASME standards, the rubber materials follow ASTM standards, and they meet AWWA standards. This ensures high quality,making them suitable for various industrial and water utility applications.

High-quality PTFE lined rubber expansion joint designed for chemical plants and industrial piping systems. This durable rubber joint with PTFE lining offers excellent corrosion and chemical resistance, effectively absorbs vibration, thermal expansion, and pressure fluctuations, and ensures long-lasting performance in harsh chemical environments.

High-quality SS304 lined sleeve wear-resistant expansion joints for industrial applications. Ideal for power plants, chemical plants, and pipelines, these durable expansion joints reduce wear, extend equipment life, and ensure reliable vibration and thermal movement absorption. Available in customizable sizes and configurations to meet your specific industrial piping needs.

High-quality EPDM expansion joint designed for flue gas desulfurization (FGD) systems. With a large diameter of DN2800 / 112 inches, this durable and flexible rubber joint effectively absorbs thermal movement, vibration, and pressure fluctuations, ensuring long-lasting performance in industrial desulfurization applications. Customizable sizes and configurations .

Raw Materials

Production process

Testing Center

After-Sales Service

We offer a 3-year warranty for standard products and a 2-year warranty for those requiring high-temperature, acid/alkali, and oil resistance. In the event of any quality issues, we commit to providing a solution within 24 hours. Should the issue be confirmed, our factory will replace the product free of charge.