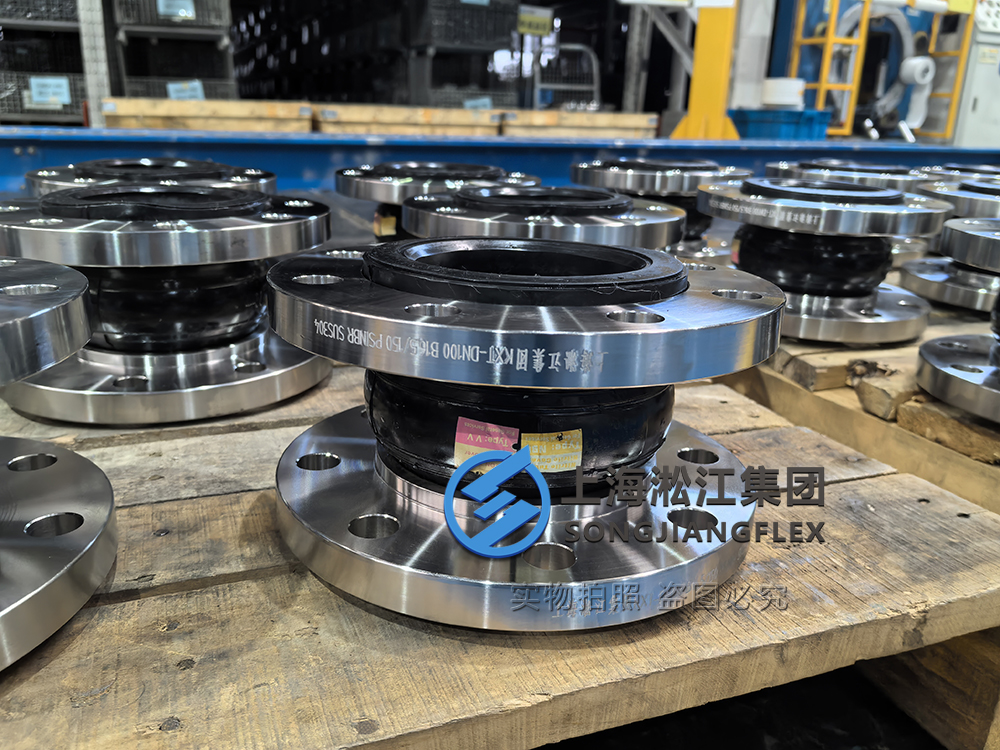

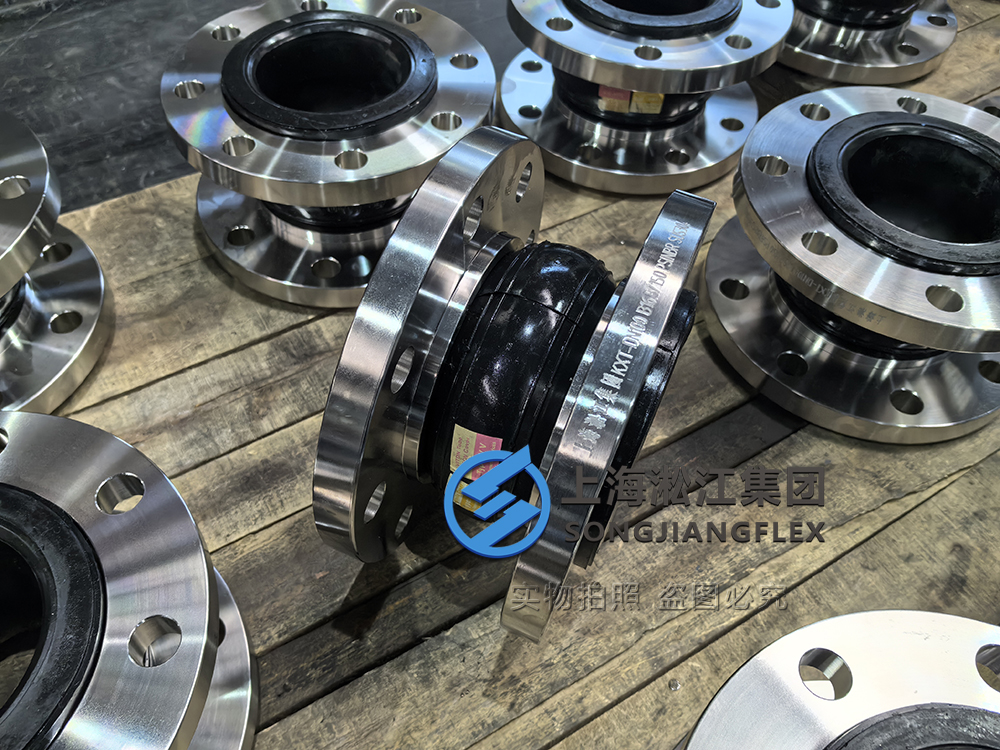

Recently, the U.S. standard high-pressure rubber expansion joints (with diameter) that we custom-manufactured for our Filipino client have been successfully completed and are now ready for shipment. As a global leader in rubber expansion joints manufacturing, we are committed to providing high-quality, customized products to ensure that every customer requirement is met with precision.

What Are Rubber Expansion Joints?

Rubber expansion joints are flexible connectors used to absorb thermal expansion, vibrations, and other physical stresses in pipeline systems. Typically used for connecting different pipeline sections, they offer flexible compensation for pipe expansion, helping to prevent damage due to thermal expansion, pipeline movement, or other factors. Rubber expansion joints are particularly suitable for systems requiring high pressure and high corrosion resistance.

Customization and U.S. Standard Compliance

To meet the specific needs of our client, we have custom-designed the high-pressure rubber expansion joints based on U.S. standards (ASME/ANSI). These standards are internationally recognized for their quality and reliability, ensuring that the products meet the highest levels of performance. During the production process, we tailored the joints’ specifications, including diameter, pressure ratings, and temperature ranges, ensuring that each product perfectly matched the client’s pipeline system requirements.

Advantages and Features of High-Pressure Rubber Expansion Joints

-

High Pressure Resistance: Our U.S. standard high-pressure rubber expansion joints are made from high-quality rubber materials capable of withstanding higher working pressures, ensuring reliable performance in harsh environments.

-

High Temperature and Corrosion Resistance: These expansion joints are ideal for high-temperature, high-pressure, and corrosive environments, such as those found in the petroleum, chemical, and power industries, reducing equipment wear and extending service life.

-

Vibration and Noise Reduction: Rubber expansion joints effectively dampen vibrations and noise, improving the stability of the pipeline system and protecting equipment from vibration damage.

-

Flexibility and Durability: They offer excellent flexibility to accommodate pipeline expansion and contraction, while maintaining exceptional durability to ensure long-term, stable performance.

Applications of Rubber Expansion Joints in High-Pressure Environments

Rubber expansion joints are widely used in high-pressure pipeline systems. In industries like petroleum, chemical, and power generation, pipelines often undergo thermal expansion and contraction in high-pressure and high-temperature environments. Rubber expansion joints absorb these changes, preventing pipe rupture or damage. In power plants, steam pipeline systems rely on rubber expansion joints to maintain safe and stable operations under extreme conditions.

Quality Control and Testing

Quality control is a fundamental aspect of our production process. From selecting raw materials to controlling manufacturing processes and conducting rigorous testing, we maintain high standards at every step. Each rubber expansion joint undergoes multiple checks before leaving the factory, including high-pressure tests, corrosion resistance tests, and aging tests, to ensure every batch of products meets international quality standards.

Customer Success Cases and Application Examples

Our U.S. standard high-pressure rubber expansion joints have been successfully applied in several international projects, including petrochemical and power plants in the Philippines. Clients have reported that our products not only enhanced pipeline safety but also reduced maintenance and repair costs. These success stories reflect our extensive experience and ability to provide efficient, reliable solutions for our clients.

Logistics and Delivery Assurance

To ensure timely delivery, we have established partnerships with multiple international logistics companies, guaranteeing smooth shipping for every order. The high-pressure rubber expansion joints custom-manufactured for our Filipino client will be shipped soon, with delivery expected in just a few days.

Summary and Call to Action

Custom-manufactured U.S. standard high-pressure rubber expansion joints not only ensure the stability of pipeline systems but also extend the service life of equipment. If you are looking for high-pressure rubber expansion joints, we offer custom solutions to meet your specific needs. Contact us for more information or place an order today, and let us provide the highest-quality solutions for your projects.