Floor mounting spring isolators play a crucial role in reducing vibrations and noise, ensuring equipment operates smoothly and efficiently. If you want to protect your machinery and improve overall performance, they are an essential choice.

A floor mounting spring isolator is a device designed to isolate vibrations from the floor to machinery. It helps minimize noise, wear, and damage to sensitive equipment, ensuring better operational efficiency. These isolators are commonly used in HVAC systems, industrial machinery, and more.

Let’s dive deeper into how these isolators work and why they’re essential in various industries.

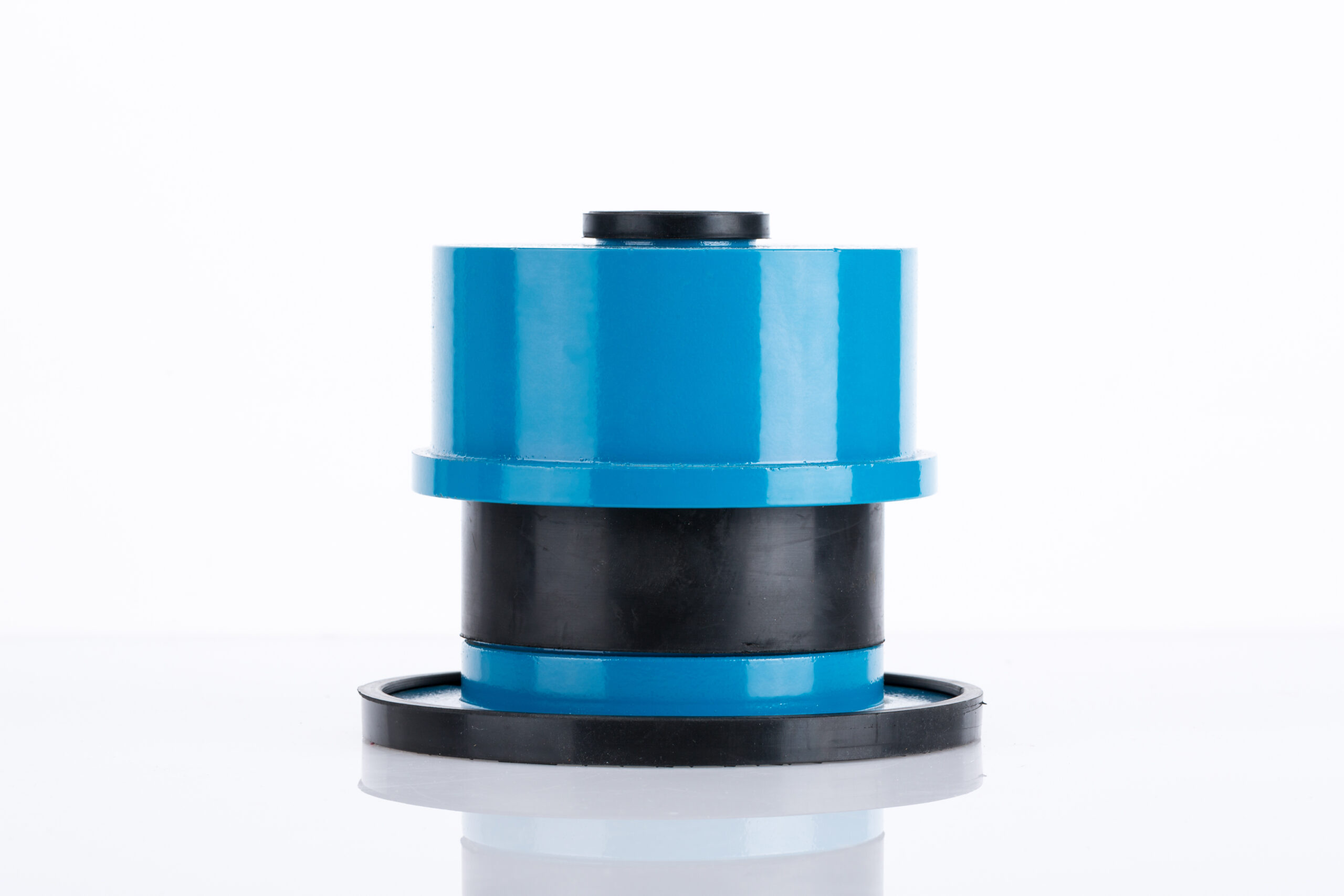

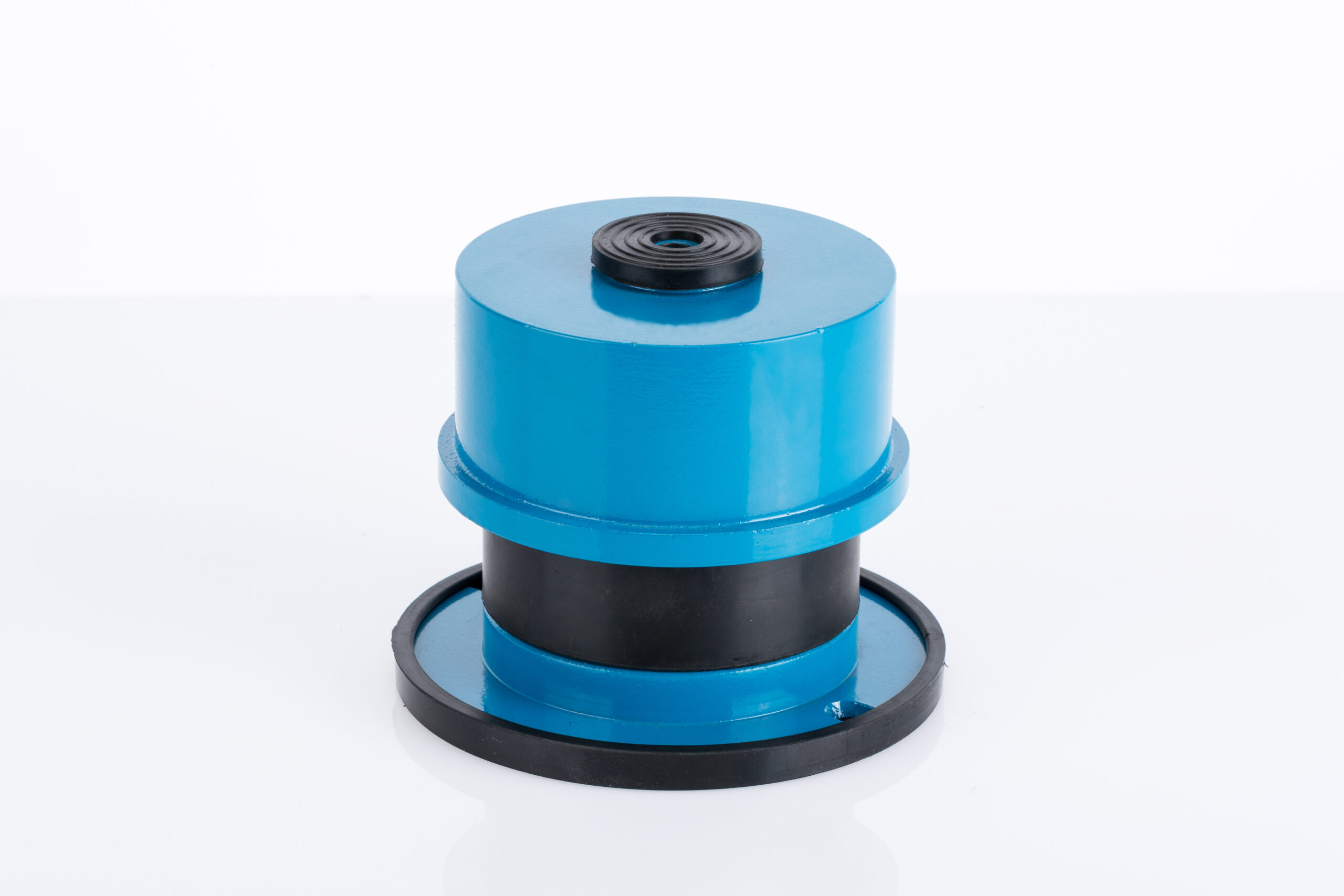

What is a Floor Mounting Spring Isolator?

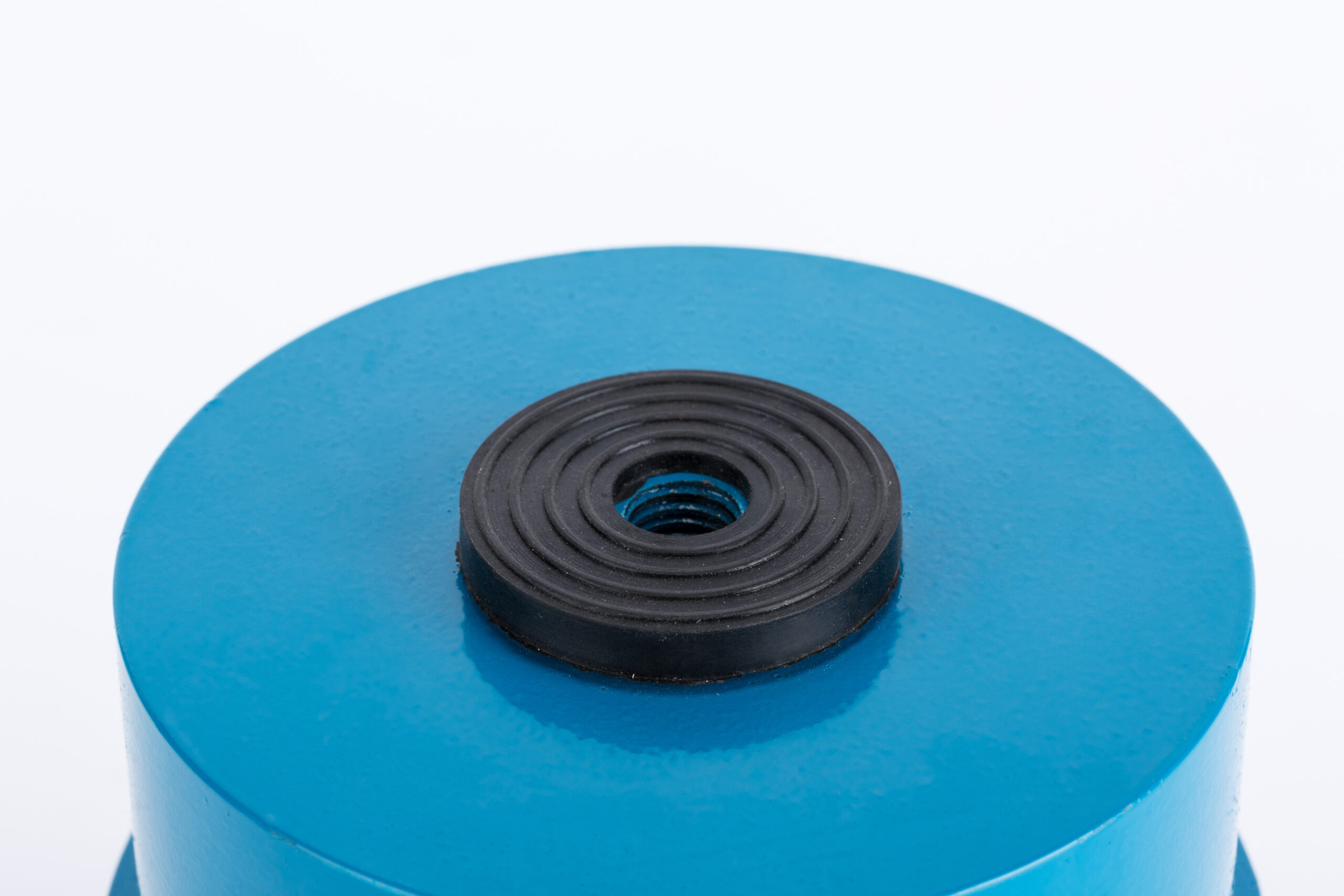

A floor mounting spring isolator is a mechanical device designed to absorb and isolate vibrations, reducing noise transmission from the floor to the connected equipment. They are typically used to support machinery and heavy equipment while minimizing vibration-related issues.

These isolators are engineered to reduce the amount of vibration transmitted from the floor to equipment. This isolation ensures that machinery operates without excessive noise or wear, which is crucial for equipment longevity.

Floor mounting spring isolators are often used in industrial settings, such as manufacturing plants, power plants, and HVAC systems, where vibration control is critical. They help protect machinery from damage caused by vibrations and maintain a quiet, stable working environment.

How Do Floor Mounting Spring Isolators Work?

Floor mounting spring isolators work by using a combination of springs and damping mechanisms to absorb and reduce vibrations. The isolators decouple the machinery from the floor, which helps to prevent the transmission of unwanted vibrations.

The isolators absorb the vibrational energy produced by machines and redirect it, preventing it from affecting other parts of the system. This process ensures that equipment remains stable and operates smoothly.

Spring isolators are designed to reduce both high and low-frequency vibrations, making them ideal for a wide range of applications. They come in various designs, each suited to different types of equipment and specific vibration frequencies. When selecting a floor mounting spring isolator, it’s important to consider the weight and operating conditions of the equipment.

What Are the Benefits of Using Floor Mounting Spring Isolators?

Using floor mounting spring isolators offers numerous benefits, including noise reduction, increased equipment lifespan, and improved operational efficiency. These isolators help create a more stable and quieter working environment.

Spring isolators minimize the impact of vibrations, reducing wear and tear on machinery. They also improve the overall efficiency of equipment by preventing operational disruptions caused by excessive vibrations.

One of the significant advantages of using spring isolators is that they can extend the lifespan of machinery by preventing vibration-induced fatigue. In addition, they contribute to better energy efficiency and reduced maintenance costs, making them a valuable investment for industrial operations.

What is the Purpose of a Spring Isolator?

The primary purpose of a spring isolator is to reduce the transmission of vibrations from machinery to the surrounding environment. This helps protect both the equipment and the infrastructure from the damaging effects of vibrations.

Spring isolators are used to minimize the impact of vibrations on both the machine and the floor. This isolation not only protects the machinery from damage but also prevents vibrations from spreading to other equipment or structures.

Spring isolators are commonly used in various applications, such as in HVAC systems, industrial machinery, and construction equipment. By isolating vibrations, they help to maintain equipment performance and prevent disruptions in production.

What are Spring Seat Isolators for?

Spring seat isolators are used to support the base of machinery while isolating the vibrations from the rest of the structure. They help prevent the transmission of vibrations to the floor or building structure.

These isolators are designed to reduce the impact of vibrations at the base of the machinery. They are especially useful in equipment with high vibration frequencies, such as compressors and pumps.

Spring seat isolators are critical in preventing damage to sensitive equipment and reducing noise levels in industrial environments. Their primary role is to provide a stable, vibration-free foundation for machinery, ensuring smooth operation and longer equipment life.

What are Floor Joist Isolators?

Floor joist isolators are used to prevent vibrations from traveling through the floor joists to the rest of the building or machinery. They help to isolate equipment and create a more stable working environment.

These isolators are typically installed between the floor joists and the equipment to prevent vibrations from being transmitted to the building’s structure. They are ideal for controlling low-frequency vibrations.

Floor joist isolators are particularly beneficial in multi-story buildings or facilities where vibration transmission can affect other floors. They are used in applications such as HVAC systems and industrial machinery to ensure a quieter, more stable operation.

What is an Isolator Mount?

An isolator mount is a support system used to attach machinery to the floor or structure while isolating it from vibrations. It works by decoupling the machinery from its base to prevent vibrations from affecting other parts of the system.

Isolator mounts are crucial in applications where machinery is prone to generating significant vibrations. They help absorb and isolate these vibrations, ensuring that the surrounding environment remains unaffected.

Isolator mounts are commonly used in the automotive, aerospace, and manufacturing industries to control vibrations in equipment such as engines, compressors, and turbines. They are designed to prevent vibrations from interfering with sensitive equipment or structures.

What Do You Need an Isolator For?

Isolators are essential in many industries to protect equipment and structures from the damaging effects of vibrations. They are used to maintain the integrity of machinery and prevent disturbances in sensitive environments.

You need isolators to protect equipment from vibrations, reduce noise, and maintain stable operating conditions. They are especially useful in industries such as manufacturing, construction, and HVAC systems.

Whether you’re dealing with industrial machinery, HVAC systems, or even residential buildings, isolators are essential for controlling vibrations. They help ensure that machinery runs smoothly and prevent potential damage caused by excessive movement or noise.

What is an Isolator and Where is it Used?

An isolator is a device designed to isolate vibrations from equipment, ensuring that machinery operates smoothly without affecting surrounding structures. They are used in various industries to reduce the impact of vibrations.

Isolators are commonly used in industrial, HVAC, and construction applications to protect equipment and structures from the harmful effects of vibrations. They help maintain a stable, quiet working environment.

Isolators are used in a wide range of applications, from industrial machinery to large construction projects. By reducing the transmission of vibrations, they contribute to enhanced performance, reduced maintenance, and extended equipment life.

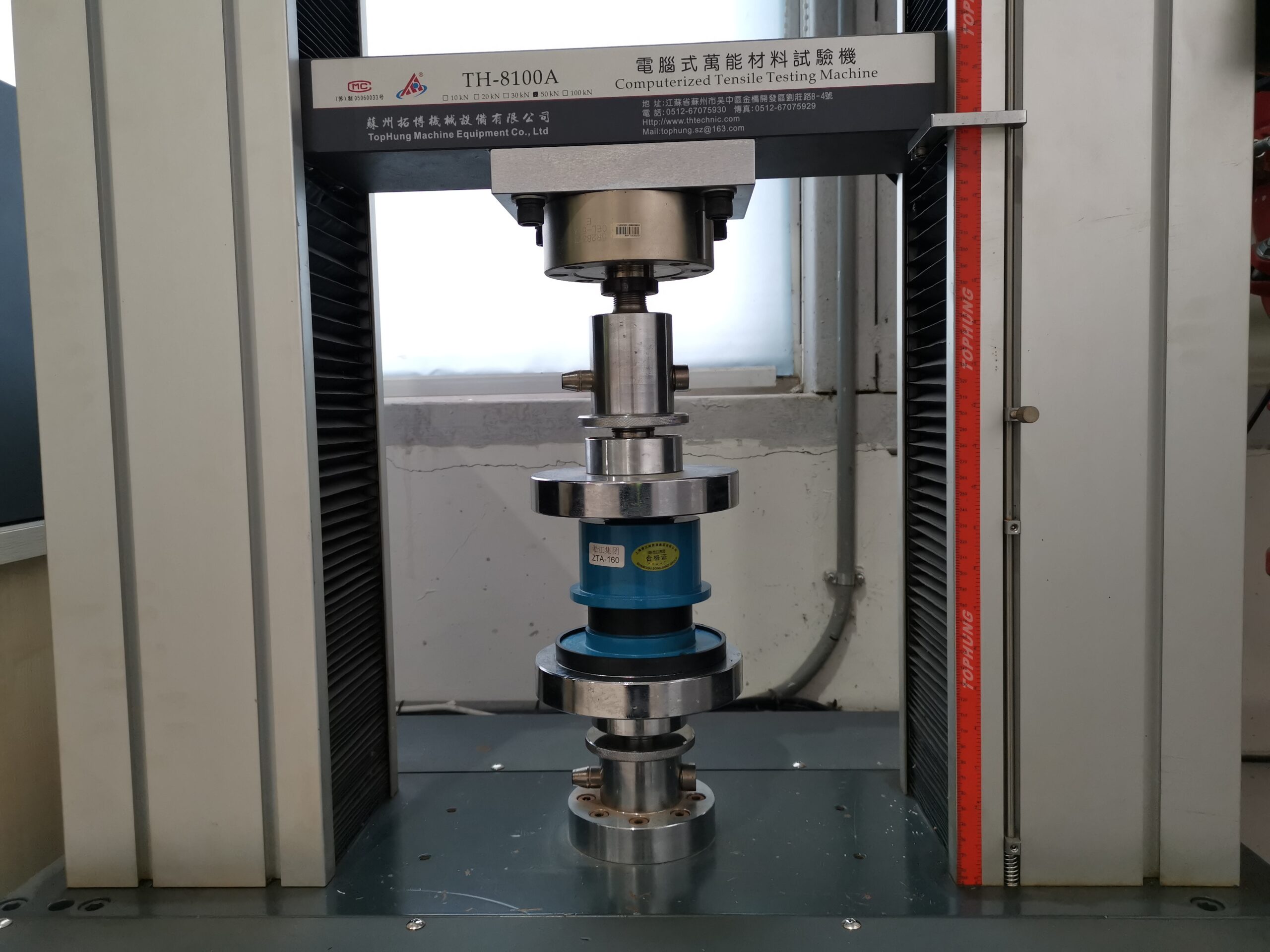

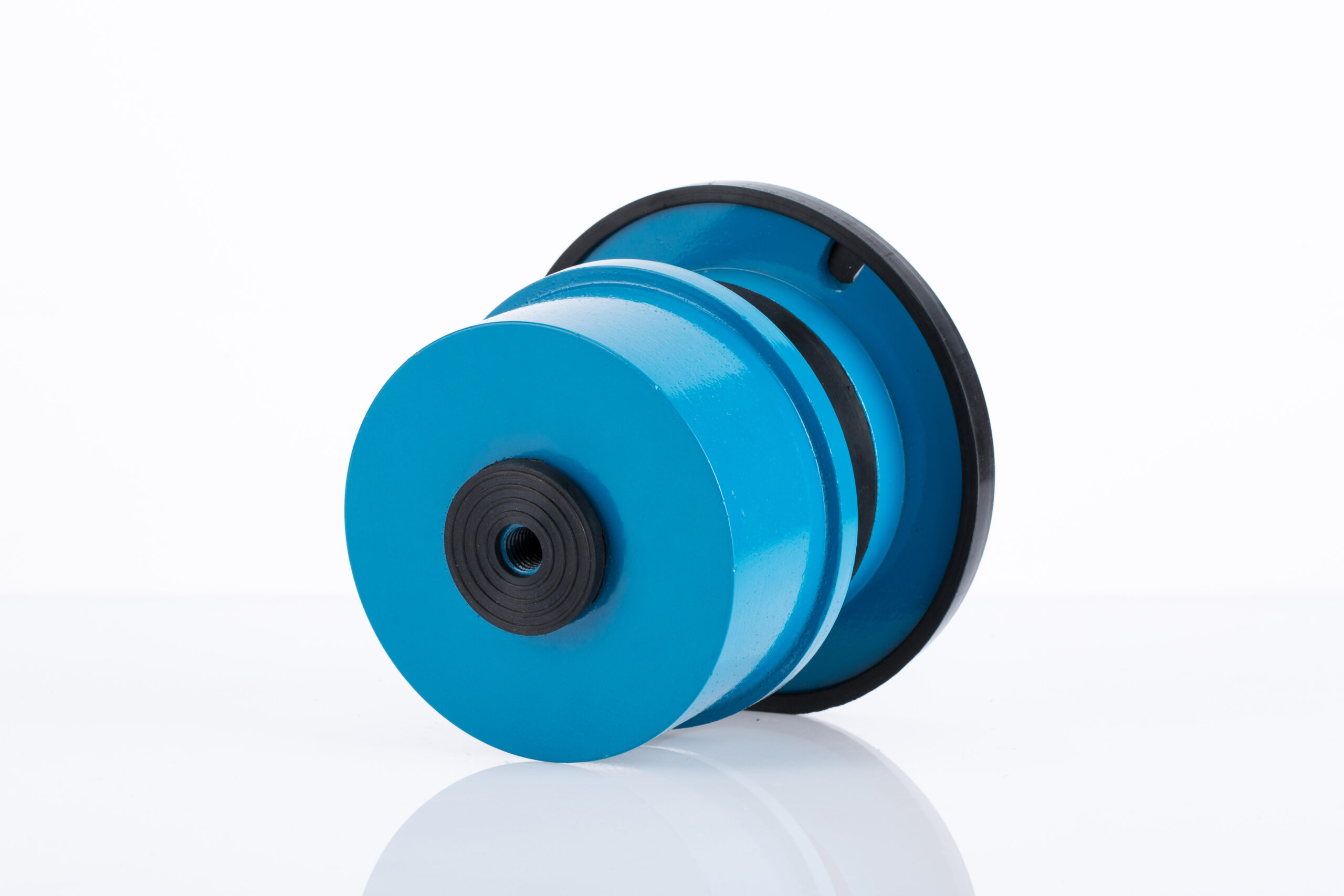

How to Install a Floor Mounting Spring Isolator?

Proper installation of floor mounting spring isolators is crucial for ensuring effective vibration isolation. The process involves selecting the right isolator, preparing the installation site, and securing the isolators to the floor and machinery.

The installation process requires careful planning and attention to detail. Start by choosing the right isolators based on the equipment and load. Then, securely mount the isolators to the floor and connect them to the equipment.

When installing floor mounting spring isolators, it’s important to ensure that they are correctly aligned and firmly attached. Improper installation can reduce the effectiveness of the isolators and may lead to vibrations that could damage equipment over time.

What Factors Affect the Performance of Floor Mounting Spring Isolators?

The performance of floor mounting spring isolators can be influenced by several factors, including the weight of the machinery, the frequency of vibrations, and the environmental conditions.

Factors such as the spring stiffness, load capacity, and environmental factors like temperature and humidity all play a role in the performance of the isolators. These factors must be considered when selecting the right isolators for specific applications.

To ensure optimal performance, it’s important to match the isolator’s specifications to the specific needs of the equipment. For example, higher vibration frequencies require different isolator characteristics than low-frequency vibrations.

Summary

Floor mounting spring isolators are essential for reducing vibrations and noise in various industrial applications. By understanding their purpose, benefits, and installation process, you can choose the right isolator for your needs, ensuring equipment longevity and operational efficiency.

Our company’s new website is now live, featuring the latest product introductions. For more details, please visit https://shsjflex.com/