Problem – Excessive equipment vibration can cause wear, noise, and premature failure.

Agitation – Without proper isolation, machinery suffers from instability and reduced service life.

Solution – Sandwich vibration isolators offer compact, durable, and efficient vibration control for various equipment types.

Sandwich vibration isolators are durable elastomer-metal components designed to absorb shock and reduce vibration in industrial and commercial equipment. Their compact design, high load capacity, and versatility make them ideal for HVAC systems, vehicles, and heavy machinery.

Let’s explore their structure, working principle, material options, types, and how to choose the right one.

What Are the Structural and Performance Advantages of Sandwich Mounts?

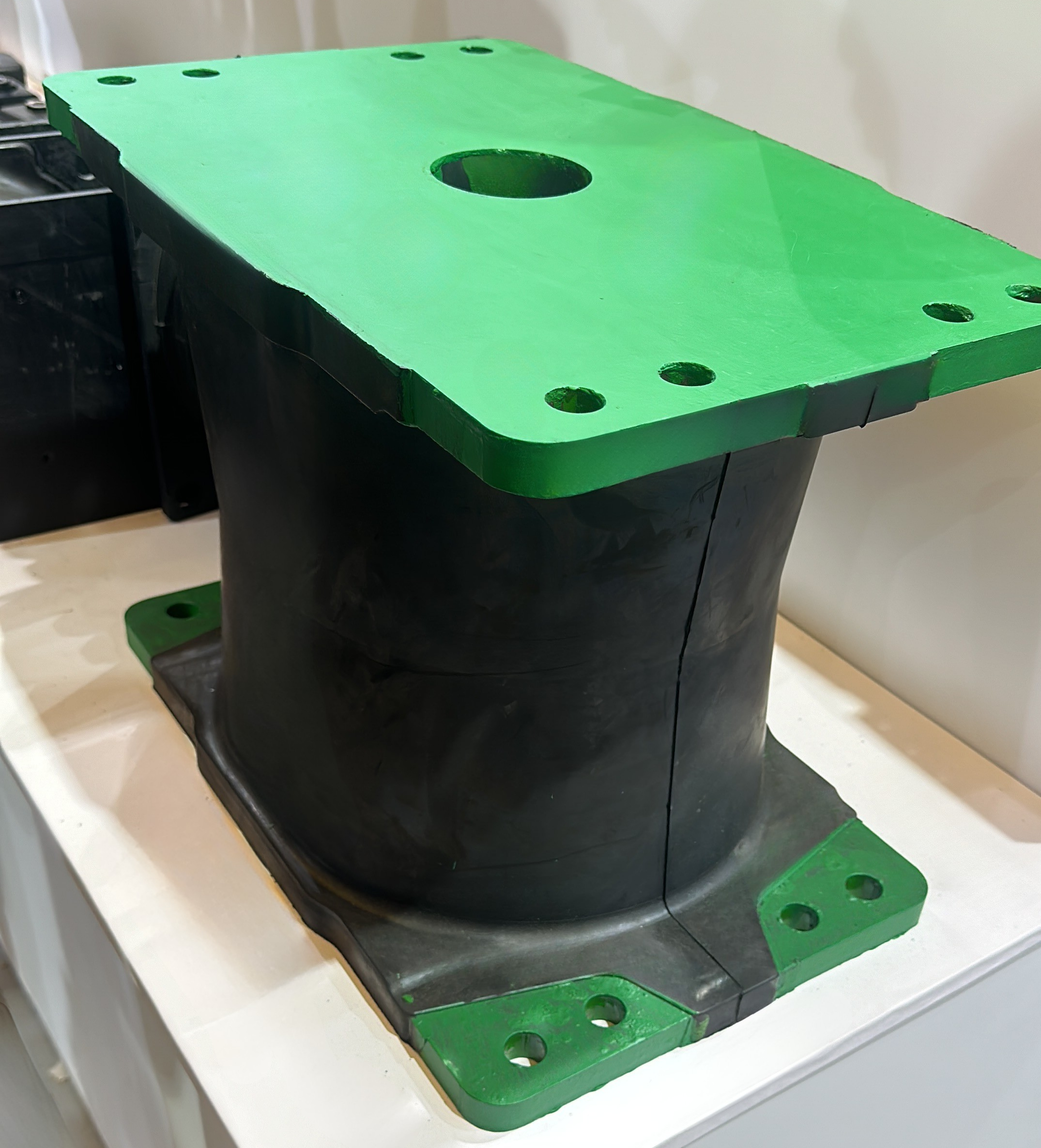

Sandwich mounts consist of a rubber elastomer core securely bonded between two metal plates. This integrated construction provides excellent mechanical strength, durability, and a lightweight profile. The use of high-strength adhesives and vulcanization techniques ensures minimal failure risk under cyclic loads.

These isolators support both static and dynamic loads, reduce mechanical vibration and noise, and extend equipment lifespan. Their modular sizes and simple installation reduce maintenance and operating costs.

Common applications include office equipment, motorcycles, small motors, HVAC systems, feeder machines, and road construction tools like vibratory rollers. Their wide size range and mounting options make them highly adaptable.

What Is the Working Principle of a Shear-Type Vibration Isolator?

Shear-type isolators primarily absorb vibrations through shear deformation of the rubber element. This design is especially effective for isolating low-frequency vibrations and sudden shocks, which are common in heavy-duty machinery.

Rubber layers deform under shear force, absorbing and dispersing kinetic energy. This prevents vibration transfer to equipment structures, minimizing fatigue and improving operational safety.

Shear isolators are widely used in hydraulic compactors, excavator hammers, mining crushers, and generator sets. Their hourglass-shaped rubber design reduces internal stress and enhances durability under extreme conditions.

What Are the Common Design Forms of Sandwich Vibration Isolators?

Sandwich isolators come in multiple configurations to suit different installation requirements:

-

Cylindrical (Bobbin) Mounts: Threaded studs on both ends; general-purpose.

-

Large Shear Mounts: Square plates without studs; ideal for high-shear applications.

-

Square Pad Mounts: Used where space is limited or surface area is large.

-

Custom Designs: Tailored for high-precision or demanding applications.

Different forms accommodate various installation angles, vibration frequencies, and space constraints. Choosing the correct shape enhances damping effectiveness and equipment protection.

Selection depends on load direction (axial or radial), mounting space, ease of maintenance, and the type of vibration (shear, compression, or impact).

What Materials Are Used in Sandwich Vibration Isolators?

Material selection plays a crucial role in vibration control performance.

Metal Components:

-

Steel or stainless steel plates and studs provide strength and corrosion resistance.

-

Aluminum may be used in lightweight or non-corrosive environments.

Elastomer Types:

-

Natural Rubber: High elasticity and fatigue resistance; not oil or heat resistant.

-

Silicone Rubber: Excellent temperature resistance and aging properties; lower tear strength.

-

Neoprene (CR): Moderate oil and chemical resistance; good for outdoor or semi-harsh environments.

Rubber choice affects temperature tolerance, chemical compatibility, and lifespan. Pairing the right rubber and metal ensures optimal vibration isolation.

For example, natural rubber performs well in indoor HVAC systems, while neoprene is better suited for industrial environments with oil exposure.

What Is the Core Function of a Sandwich Vibration Isolator?

These isolators act as cushions between vibrating equipment and their mounts, preventing harmful oscillations from affecting machine components and structures.

They absorb vibration and shock, minimize equipment noise, and prevent structural fatigue. As a result, machinery runs more smoothly and requires fewer repairs.

This leads to better workplace safety, reduced operator fatigue, and extended lifespan of bearings, shafts, and electronic components within the machinery.

How to Choose the Right Sandwich Vibration Isolator?

Choosing the correct isolator involves assessing multiple factors:

-

Load-bearing requirements (static and dynamic)

-

Type and direction of vibration

-

Environmental conditions (temperature, oil, UV exposure)

-

Mounting space and thread compatibility

Improper selection can reduce vibration control performance and lead to premature failure. Tailored solutions ensure optimal performance in real-world operating conditions.

Consult with experts who can evaluate your equipment needs and provide precise recommendations on rubber hardness, mount geometry, and thread size for maximum efficiency.

Summary:

Sandwich vibration isolators are a reliable, low-maintenance solution for reducing equipment noise, vibration, and wear. Proper selection maximizes performance and extends machinery life.