Problem – Standard rubber joints often fail in demanding environments where custom dimensions, high temperature, or vacuum resistance are required.

Agitation – These failures can lead to system breakdowns, leaks, or equipment damage, especially in power plants, chemical industries, and vacuum pipelines.

Solution – Hand-built rubber expansion joints offer tailored performance through reinforced, multi-layer designs ideal for extreme applications.

What is a hand-built rubber expansion joint?

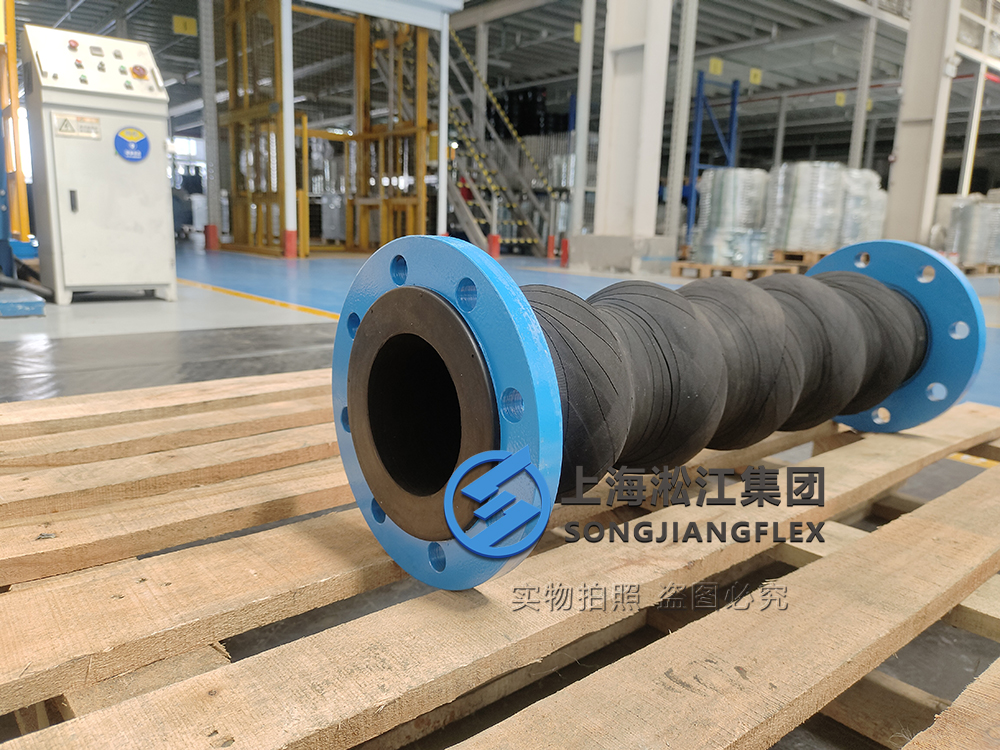

A hand-built rubber expansion joint is a flexible connector constructed manually through a multi-step process involving fabric wrapping, rubber layering, and vulcanization without a fixed mold. Unlike molded joints, it allows for non-standard diameters and lengths, making it ideal for systems with unique layout constraints or extreme operating conditions.

These joints are often reinforced with embedded steel wires or metal rings to provide high stability under vacuum or pressure. Their custom-built nature supports usage in thermal plants, chemical piping, negative pressure lines, or aggressive media handling systems.

Snippet:

A hand-built rubber expansion joint is a custom-engineered flexible connector made without a mold. It features fabric and rubber layers reinforced with steel, ideal for high-temperature, vacuum, and chemical applications.

What are the types of hand-built rubber joints?

Hand-built rubber expansion joints are categorized based on their reinforcement structure and application environment:

-

General-purpose: Flexible and corrosion-resistant, used in standard piping systems.

-

Vacuum type: Internally reinforced with steel wire or rings to resist collapsing under negative pressure.

-

High-temperature type: Made of heat-resistant rubber like Viton or EPDM, suitable for systems up to 204°C (400°F).

-

Heavy-duty (High-pressure): Multiple reinforced fabric layers to withstand up to 225 PSIG.

-

Customized type: Tailored to non-standard dimensions, shapes, or connection styles according to client drawings or special site needs.

Snippet:

Hand-built rubber joints include vacuum-resistant, high-temperature, high-pressure, and fully customized types. Each is designed for specific engineering needs using reinforced, layered rubber and fabric.

When are control units required for rubber expansion joints?

Control units are mechanical limiters designed to prevent over-extension, compression, or lateral displacement in rubber joints. They are essential in:

-

Preventing over-travel: Stops joint from pulling apart or collapsing.

-

Absorbing thrust force: Protects pumps, valves, and flanges from expansion force.

-

Unstable support situations: For suspended or buried pipes.

-

High-pressure or high-movement systems: Where additional safety is required.

Components of a control unit:

-

Control rods

-

Limit nuts (double nuts)

-

Steel washers

-

Restraining rings

-

Tie rods or plates

These elements protect the joint and adjacent equipment from dynamic loads or installation errors.

Snippet:

Control units are crucial in systems with pressure, movement, or poor pipe support. They ensure the rubber joint doesn’t exceed its movement range or suffer damage.

How do hand-built joints handle vacuum and high-temperature conditions?

Hand-built joints are engineered with robust reinforcement layers to withstand severe operating environments:

-

Temperature range: From -30°C up to 250°C (482°F) depending on rubber type

-

Rubber options: EPDM (up to 149°C/300°F), Viton (up to 204°C/400°F)

-

Fabric reinforcement: Multiple plies of aramid or high-strength polyester for durability

-

Pressure resistance: Can exceed 225 PSIG depending on size

-

Vacuum rating: Fully vacuum-rated across all diameters, achieving 30″ Hg

These features make hand-built joints indispensable in power plants, refineries, chemical process plants, and vacuum pipelines.

Snippet:

Designed for extreme heat and full vacuum, hand-built joints use high-performance rubber and reinforced fabrics to ensure long-lasting, safe operation in critical systems.

How does the hand-crafted process ensure quality?

Each joint is built by skilled technicians with extensive experience in layering and vulcanizing rubber:

✅ Material control: Only high-quality rubber compounds and fabrics are used for elasticity, chemical resistance, and strength.

✅ Craftsmanship: Every product is built to specification without relying on molds, ensuring complete dimensional flexibility.

✅ Inspection: Every unit undergoes hydrostatic pressure, fatigue, temperature resistance, and vacuum integrity testing before shipment.

Warranty:

-

Standard use: 3 years

-

Acid-alkali or high-temp use: 2 years

-

Custom products: 1 year

If a quality issue occurs, we guarantee a written response within 12 hours and a solution within 24 hours—with free replacements for confirmed product faults.

Snippet:

Every hand-built joint is crafted with strict material control and thorough testing. With up to a 3-year warranty and fast response support, performance is guaranteed.

Summary

Hand-built rubber expansion joints provide custom-fit, high-performance solutions for challenging environments involving vacuum, temperature extremes, and non-standard pipe layouts. They ensure long-term reliability through expert craftsmanship and rigorous quality testing.