Modern electronic systems and precision instruments are becoming increasingly sensitive to vibration and shock. Even small amounts of vibration can reduce accuracy, shorten equipment lifespan, and cause performance instability. An air damping vibration isolator is designed to solve this problem by combining air damping, spring support, and rubber isolation in one compact structure.

What Is an Air Damping Vibration Isolator?

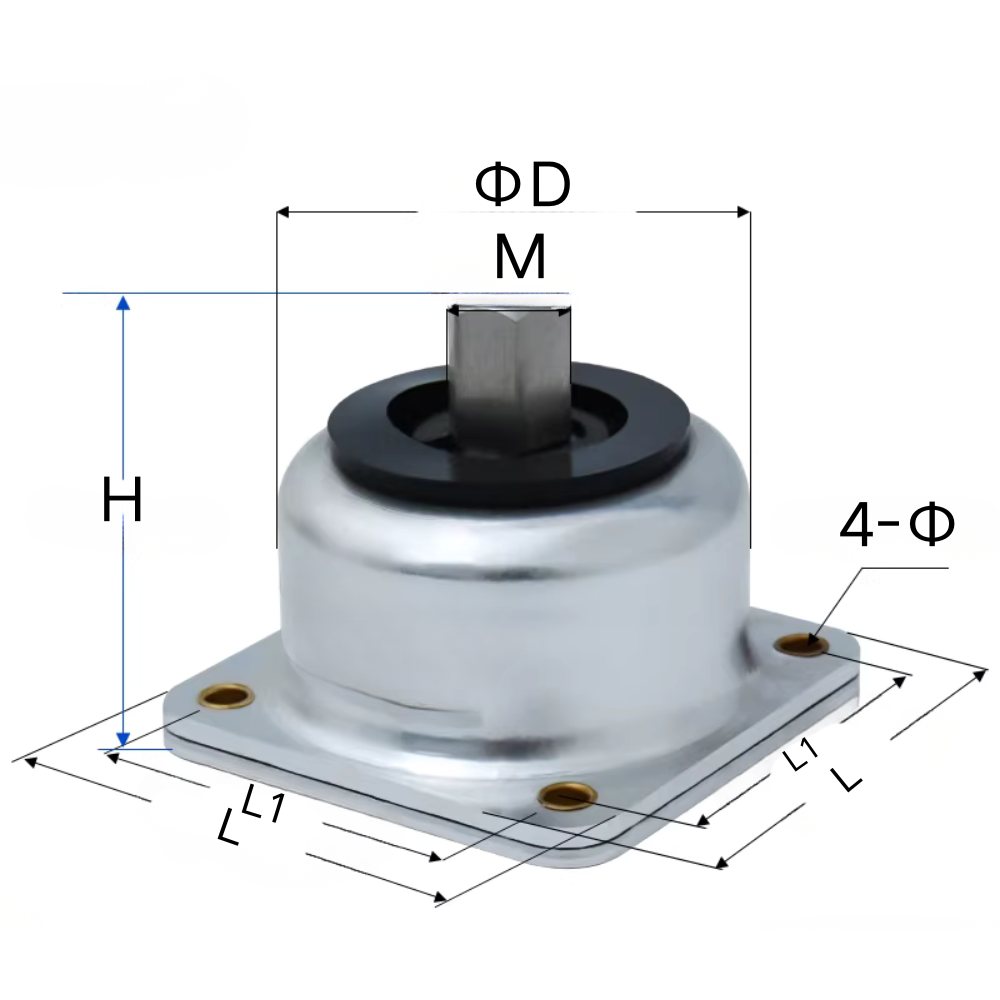

An air damping vibration isolator is a compact anti-vibration device that uses a rubber air bladder, spring, and aluminum housing to reduce vibration transmission.

When the isolator compresses or expands, air flows through internal holes, creating friction that produces damping. This mechanism effectively absorbs shock energy and stabilizes sensitive equipment.

With a load range of 0.4–18 kg, this type of isolator is ideal for lightweight but vibration-sensitive systems.

How Does Air Damping Improve Vibration Control?

Unlike traditional rubber mounts, air damping isolators provide both elasticity and controlled damping.

The internal air chamber helps:

-

Absorb sudden shocks

-

Reduce resonance

-

Stabilize vertical loads

-

Improve system accuracy

The combination of large static deflection and low natural frequency allows the isolator to block high-frequency vibration effectively.

Key Features of Air Damping Vibration Isolators

-

High-quality rubber air bladder for excellent shock absorption

-

Durable aluminum housing for long service life

-

Spring and air structure for stable damping

-

Compact design for onboard equipment

-

Optimized for vertical load support

These features make the isolator reliable in environments where vibration control is critical.

Applications in Modern Industries

Air damping vibration isolators are widely used in industries that require stability and precision.

Common applications include:

-

Precision instruments

-

Measuring devices

-

Wireless communication equipment

-

UAV engines and gimbal systems

-

Onboard electronic systems

-

Optical and testing equipment

They are especially useful for aerial photography equipment and drone electronics, where vibration can directly affect image quality and performance.

Why Choose an Air Damping Isolator for Sensitive Equipment?

Precision equipment often operates in environments with continuous vibration. Without proper isolation, this vibration can cause:

-

Measurement errors

-

Signal interference

-

Component wear

-

System instability

Air damping isolators provide stable, long-lasting, and efficient vibration control while maintaining compact size and lightweight construction.

Conclusion

An air damping vibration isolator offers a balanced solution between shock absorption, durability, and precision performance. With its advanced air-spring-rubber structure and low natural frequency design, it is an ideal choice for protecting sensitive electronic and measuring equipment in modern industrial and aerospace applications.