What is the best vibration isolator for an electric screw press?

When operating an electric screw press, excessive vibrations can damage the machinery. The right vibration isolator ensures smooth performance and prevents equipment wear, reducing downtime.

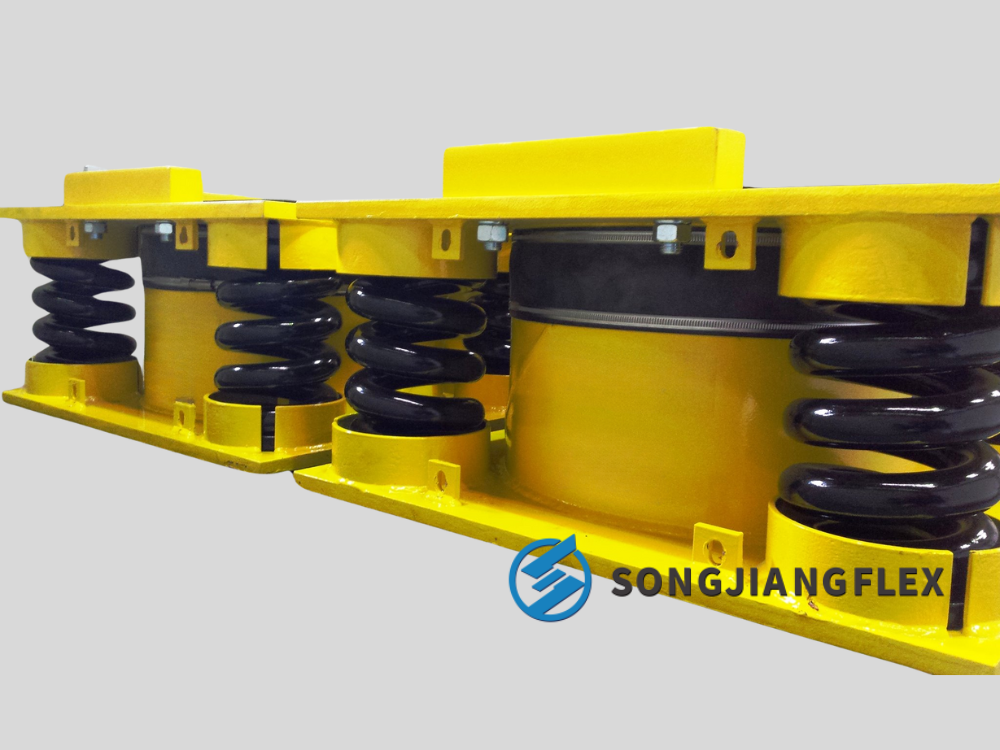

The best vibration isolator for an electric screw press reduces vibrations, extending the machine’s lifespan and enhancing stability. Various types of isolators, like spring vibration isolators and pneumatic vibration isolators, can help achieve this.

Let’s explore the ideal vibration isolators for electric screw presses.

What does a vibration isolator do for an electric screw press?

Vibration isolators play a crucial role in protecting electric screw presses by reducing vibrations that can lead to machinery malfunction or excessive wear. These isolators work by creating a buffer between the machine and its mounting surface, absorbing and dampening vibration forces.

A well-chosen vibration isolator can extend the life of the machine by reducing mechanical strain, noise, and wear. Common solutions include spring vibration isolators, vibration isolator pads, and pneumatic vibration isolators, each offering distinct benefits for various use cases.

For electric screw presses, using vibration isolators ensures greater precision, lower maintenance needs, and overall improved performance.

What is the best way to isolate vibrations?

To effectively isolate vibrations, the choice of isolator must match the machine’s specific requirements, such as its weight, operational frequency, and environment. There are several methods for isolating vibrations, with the use of vibration isolators being the most efficient.

The best way to isolate vibrations is by installing spring vibration isolators, pneumatic vibration isolators, or vibration isolator pads. These devices absorb and dampen vibrations, ensuring stability and reducing noise during the machine’s operation.

For optimal vibration isolation in electric screw presses, an active vibration isolation table may also be considered, offering a dynamic solution for minimizing disruptive vibrations.

What is a good vibration isolator?

A good vibration isolator must provide effective damping, durability, and adaptability to different operational conditions. It should reduce both the intensity and transmission of vibrations while remaining robust enough to withstand continuous usage.

A high-quality vibration isolator should efficiently minimize vibrations, be resistant to environmental factors, and have a long lifespan. Spring vibration isolators and pneumatic vibration isolators are some of the best options available for electric screw presses, delivering reliable performance in a variety of settings.

Choosing a good vibration isolator involves assessing the machine’s specific needs and selecting a solution that offers the best combination of flexibility and strength.

What is the purpose of a vibration isolator?

The primary purpose of a vibration isolator is to prevent vibrations from being transmitted from one component to another, protecting sensitive equipment from excessive stress. For electric screw presses, vibration isolators act as a safeguard, reducing vibrations and the wear they cause.

By reducing vibration transfer, vibration isolators minimize machine damage, prevent noise pollution, and improve operational precision. Options like spring vibration isolators and pneumatic vibration isolators help achieve this by cushioning machinery from the impacts of vibration forces.

Overall, the purpose of a vibration isolator is to enhance equipment longevity and maintain a stable working environment.

What is the difference between a vibration absorber and a vibration isolator?

Though often confused, vibration absorbers and vibration isolators serve different purposes. A vibration absorber dissipates energy to reduce vibration magnitude, while a vibration isolator reduces the transfer of vibration between connected parts.

Vibration absorbers are most effective at specific frequencies, acting as a damping device. Vibration isolators, such as spring vibration isolators, are designed to separate machinery from its base, reducing the transmission of vibrational energy.

For electric screw presses, vibration isolators are the preferred solution to minimize the transfer of disruptive vibrations and ensure operational stability.

How do I choose a vibration isolator?

Choosing the right vibration isolator involves several factors, including the machine’s weight, the frequency of vibrations, and the surrounding environment. Electric screw presses, for example, require isolators that can handle high-frequency vibrations and provide strong mechanical support.

When selecting a vibration isolator, consider options such as spring vibration isolators and vibration isolator pads, both of which offer effective solutions for vibration control. Pneumatic vibration isolators are another viable option, particularly for applications where high precision and dynamic performance are critical.

Custom solutions, such as active vibration isolation tables, can further improve vibration control based on specific operational needs.

What are the disadvantages of dynamic vibration absorbers?

While dynamic vibration absorbers are effective in certain applications, they do have some drawbacks. Their design complexity makes them difficult to install and maintain, and they are often limited to specific frequencies. This means that dynamic absorbers may not perform well in environments with varying vibration frequencies.

Additionally, dynamic absorbers may require more frequent maintenance and adjustments, which can lead to higher operational costs. In contrast, spring vibration isolators and pneumatic vibration isolators offer a broader range of vibration control with less complexity and maintenance.

For electric screw presses, where consistent performance and reliability are key, vibration isolators are generally the more suitable choice.

How do vibration isolators improve the lifespan of electric screw presses?

Vibration isolators play a key role in extending the lifespan of electric screw presses by reducing the mechanical stress and damage caused by constant vibrations. By isolating the machine from its surroundings, these devices prevent wear and tear on key components.

Spring vibration isolators and vibration isolator pads are particularly effective in enhancing equipment longevity. They minimize vibration impact, reduce noise, and stabilize the machine, allowing it to operate at peak performance for longer periods.

Overall, vibration isolators can significantly lower maintenance costs and downtime, contributing to the long-term efficiency of electric screw presses.

Summary

Choosing the right vibration isolator for an electric screw press is crucial to improve performance and extend the machine’s lifespan.