Air rubber vibration isolators, also known as air springs, are flexible damping components that use compressed air as the working medium. Compared to traditional metal springs or hydraulic cylinders, they provide better adaptability, quieter operation, and smoother force transmission.

Structure and Working Principle

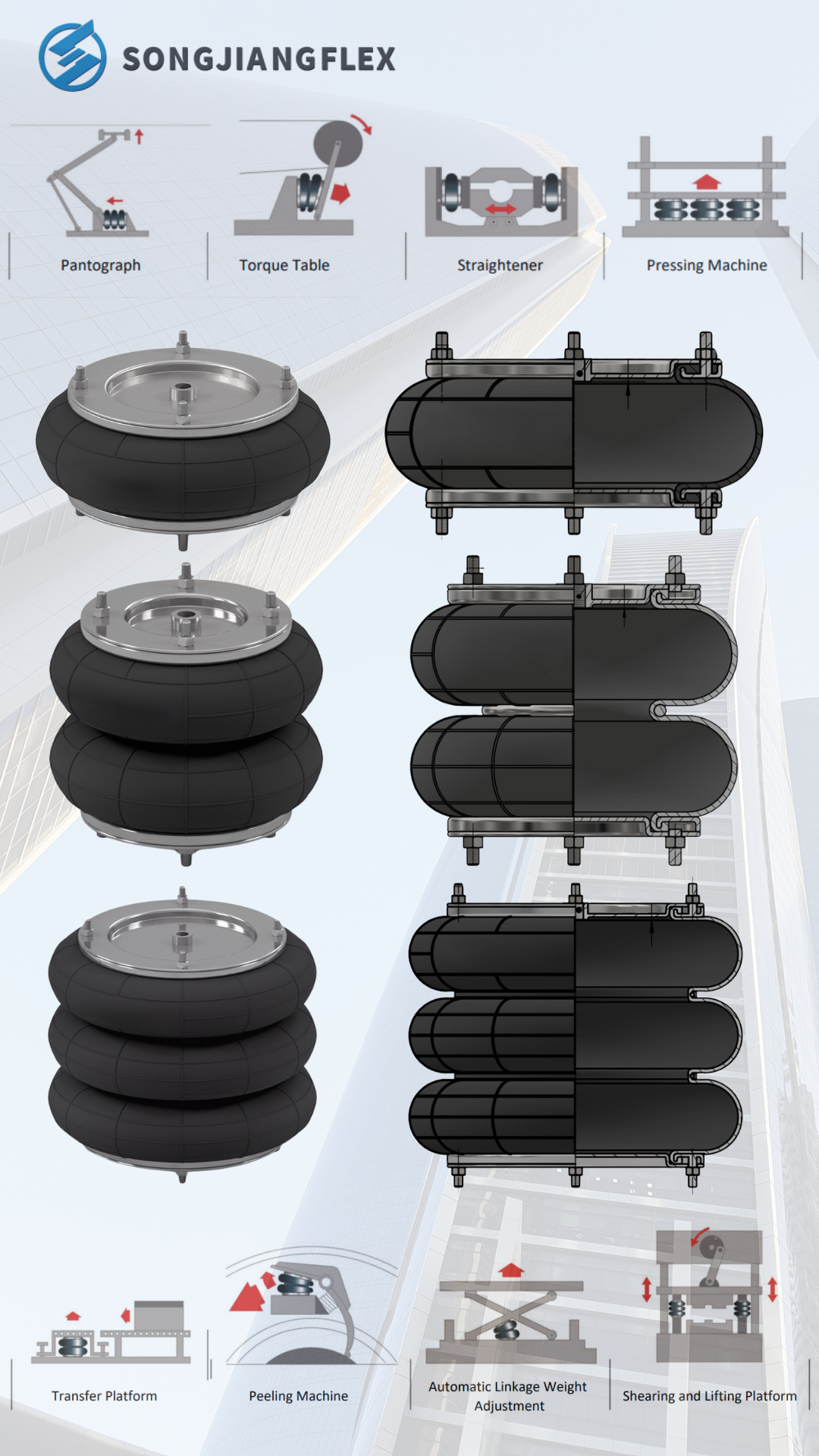

An air rubber isolator consists mainly of a reinforced rubber membrane and end plates. When compressed air is introduced, the internal pressure expands the rubber body, forming a flexible air chamber that absorbs vibration and compensates for motion.

By adjusting the internal air pressure, the stiffness and damping characteristics can be tuned to meet different application needs.

Performance Range

Air rubber vibration isolators can handle a wide range of working loads and motions. Typical specifications include:

-

Lifting Force: 0.5 kN – 440 kN

-

Diameter: 60 mm – 950 mm

-

Maximum Stroke: up to 455 mm

-

Working Medium: Standard industrial compressed air

-

Connection Type: Standard threaded connections

Typical Applications

Air rubber isolators are widely used in equipment that requires smooth motion, vibration reduction, or height adjustment. Common applications include:

-

Scissor lift platforms

-

Peeling and trimming machines

-

Railway pantographs (overhead collectors)

-

Conveyor lateral guide systems

-

Load-balancing linkages

These isolators are especially suited for installations with complex geometries, exposure to environmental stress (e.g., solar radiation), or the need for oil-free damping.

Advantages of Air Rubber Isolators

-

Adjustable stiffness via internal air pressure

-

Quiet operation, no metal-to-metal contact

-

Clean damping, free from oil or grease

-

Long stroke capability for large displacement

-

Durable and low-maintenance

Selection Considerations

When choosing an air rubber vibration isolator, the following parameters should be considered:

-

Load weight (kN)

-

Required stroke/travel

-

Diameter and space constraints

-

Air supply capability

-

Working environment (e.g., temperature, UV exposure)

Different application scenarios may require custom specifications, especially in automation or dynamic systems.

Service Life and Maintenance

Air rubber isolators typically have a long service life, especially when operated under clean, dry, and stable compressed air conditions. Periodic inspection of air pressure and rubber integrity is recommended.

Conclusion

Air rubber vibration isolators offer a clean, adjustable, and efficient solution for vibration control and motion compensation in industrial systems. Their versatile design makes them suitable for a broad range of modern engineering applications.