Product Introduction: What Is a Titanium Expansion Joint?

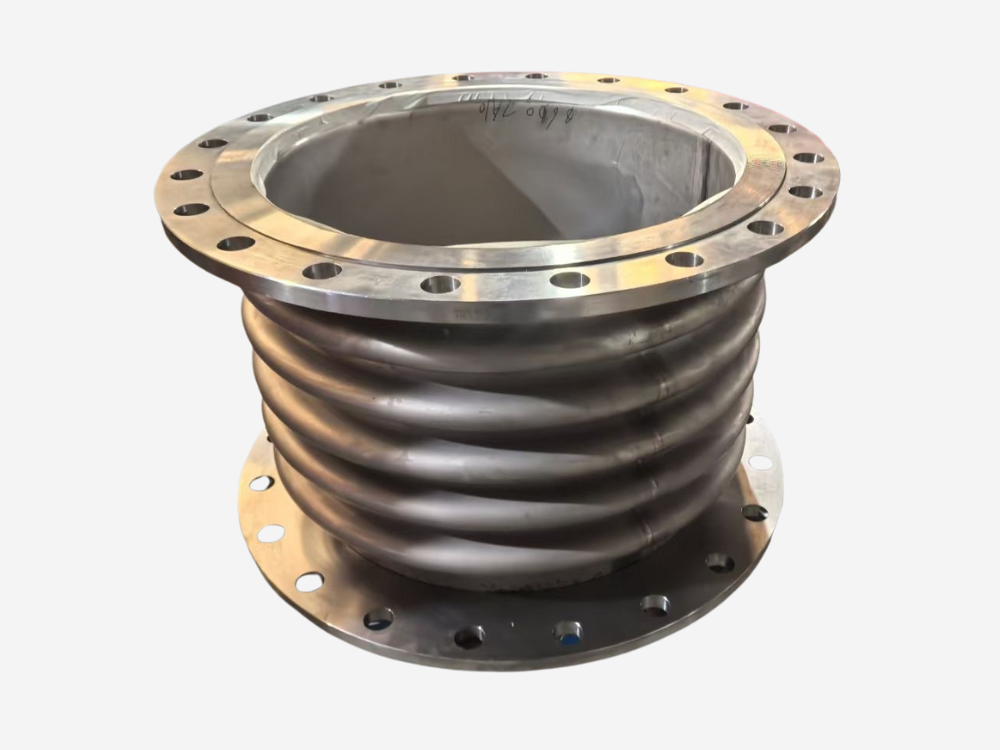

A Titanium Expansion Joint is a metallic expansion joint primarily made from titanium.

It is widely used in industries such as chemical processing, pulp and paper, marine engineering, power generation, and pharmaceuticals thanks to its exceptional corrosion resistance, lightweight design, high strength, and excellent heat resistance.

The joint consists of titanium corrugated bellows, end flanges, and connecting pipe sections.

Using the vanstoning process, the titanium bellows are flared over the flange faces, ensuring that all wetted parts are made of titanium while the flanges can be made from carbon steel or stainless steel for cost-effectiveness.

Key Features of Titanium Expansion Joints

-

Outstanding Corrosion Resistance

Titanium offers superior resistance to chloride ions, chlorine, and chloride solutions, making it ideal for highly corrosive environments such as bleaching plants, chlor-alkali facilities, and seawater desalination systems. -

Lightweight and Long Service Life

Compared to 316L and 317L stainless steel, titanium bellows last much longer when exposed to corrosive media, reducing maintenance costs and downtime. -

Advanced Fabrication Technology

Manufactured using precision forming and vanstoning techniques, ensuring excellent sealing performance, high strength, and reliable compensating capability. -

Superior Flexibility and Vibration Absorption

Effectively absorbs thermal expansion, pipeline vibration, and installation misalignment, protecting your pipeline system from mechanical stress and ensuring stable operation.

Technical Specifications of Titanium Expansion Joints

-

Material: Pure titanium (TA1 / TA2), flanges available in carbon steel or stainless steel

-

Pressure Rating: Customizable (commonly 1.0 MPa, 1.6 MPa, 2.5 MPa)

-

Connection Type: Flange connections (GB/T9119-2010 or other standards)

-

Applicable Media: Chlorides, acids, alkalis, seawater, and other corrosive fluids

-

Sizes: Customizable in diameter, length, and compensation range based on project requirements

Typical Applications of Titanium Expansion Joints

-

🏭 Pulp & paper bleaching pipeline systems

-

⚗️ Chlor-alkali chemical plant pipelines

-

🌊 Seawater desalination plants and marine engineering projects

-

🚢 Shipboard piping systems

-

💊 Pharmaceutical and food processing equipment

Titanium’s excellent suitability for highly corrosive conditions significantly enhances the durability and lifespan of piping expansion joints, reducing maintenance frequency and operational costs.

Selection Tips for Titanium Expansion Joints

-

Choose titanium expansion joints for chloride-rich, chlorine-containing, or seawater environments

-

Use them in high-temperature or high-vibration pipeline systems for stable performance

-

Consider switching to titanium when stainless steel expansion joints fail prematurely due to corrosion

-

Consult your supplier for custom sizes, lengths, pressure ratings, and flange types to meet your specific project needs

Installation and Maintenance Guidelines

-

Always avoid twisting or overstretching the titanium bellows during installation

-

Ensure precise alignment of connected pipes to prevent side loads on the bellows

-

Protect the bellows from welding heat and sparks during construction work

-

Install chloride ion removal devices if the water contains more than 25 mg/L of chloride to prevent pitting corrosion

-

Conduct regular inspections for leaks, cracks, or deformation to ensure safe and long-term operation

Conclusion: The Best Choice for Extreme Corrosion Resistance

Titanium Expansion Joints offer a reliable, durable, and high-performance solution for highly corrosive and demanding industrial environments where stainless steel cannot last long.

By choosing titanium, you can reduce maintenance costs, improve operational safety, and extend the lifespan of your pipeline systems.

We also provide customized titanium expansion joints to match your exact project requirements.

📩 Contact us today for a free consultation and quotation!